Method for spring sizing by using metal transition superplasticity

A metal phase transformation and superplastic technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as unqualified spring size, and achieve the effect of small stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

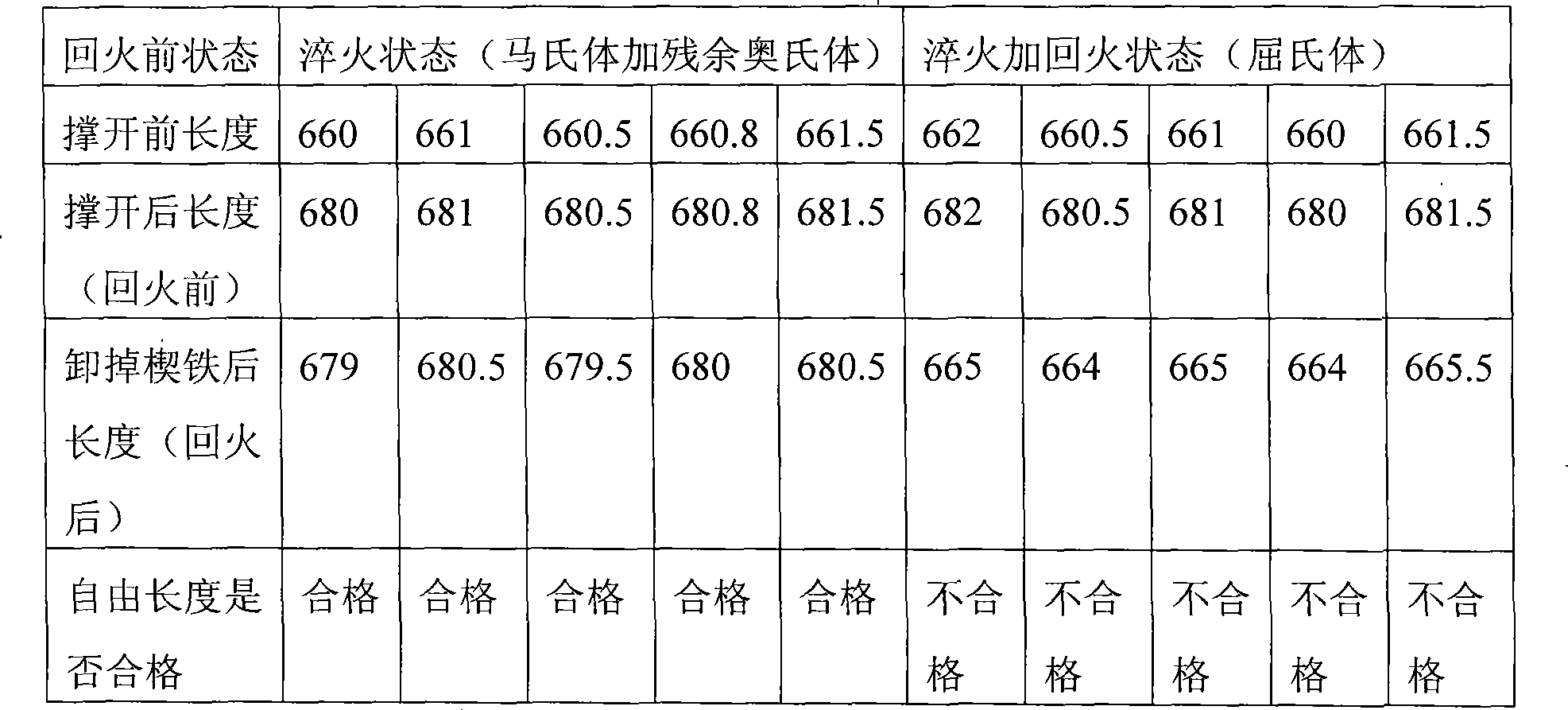

[0006] Specific implementation mode 1: This implementation mode is completed by the following steps: 1. Use tools and process equipment to continuously apply force to the out-of-tolerance part of the spring to fix it within the tolerance range; 2. Put the spring together with the tools into the furnace for heat treatment, The spring undergoes a phase change during the heat treatment process, and the spring utilizes the superplasticity of the spring to undergo plastic deformation during the phase change; 3. Remove the process equipment after being released from the furnace.

specific Embodiment approach 2

[0007] Embodiment 2: The tools and process equipment in this embodiment are hammer iron and wedge iron. Use a hammer to insert a wedge iron between the spring coils so that the spring is in a state of free length.

specific Embodiment approach 3

[0008] Embodiment 3: The heat treatment in this embodiment is normalizing, quenching and tempering, wherein the tempering temperature is 440° C., and the holding time is 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com