Deviation rectifying method and structure for inclined prestress pipe pile

A technology of prestressed pipe piles and inclined directions, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of high cost, uncontrollable, hidden safety hazards, etc., and achieve improved safety performance, low cost, and easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

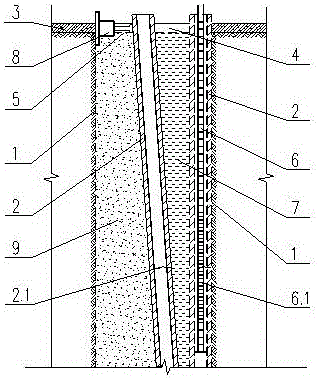

[0025] A deviation correction method for inclined prestressed pipe piles of the present invention is that the method is to incline pipe piles 2 (such as figure 1 When rectifying the deviation of the pipe pile drawn by the solid line in the middle, follow the steps below:

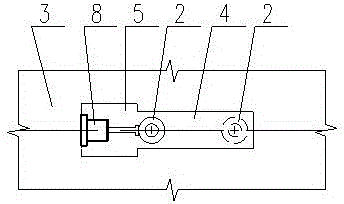

[0026] Step 1, cushion repair: Excavate the original geological soil layer 1 around the inclined pipe pile 2, so that the pile head end face of the pipe pile 2 is 200-350mm higher than the original geological soil layer, and then the excavated original geological soil layer Concrete is poured on the layer 1 to lay the repair cushion 3. When laying the repair cushion 3, a guide groove 4 is prefabricated on the repair cushion 3, so that the pile head of the pipe pile 2 can pass through the guide groove 4. A jack installation groove 5 for placing a jack is reserved on the repa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com