Preparation method of anode material for lithium ion batteries

A lithium-ion battery and negative electrode material technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems that high conductivity and high tap density cannot be achieved, and the stacking density does not play a big role, so as to achieve the optimization of electrochemistry Performance, reduction of volatilization, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The synthetic method of lithium-ion battery negative electrode material described in the present embodiment specifically comprises the following steps:

[0022] (1) At room temperature, make a mixed solution of butyl titanate, terephthalic acid, methanol and dimethylformamide according to the molar ratio of 1:2:15:60, and mechanically stir and ultrasonically vibrate for a long enough time Time to mix the medicines evenly.

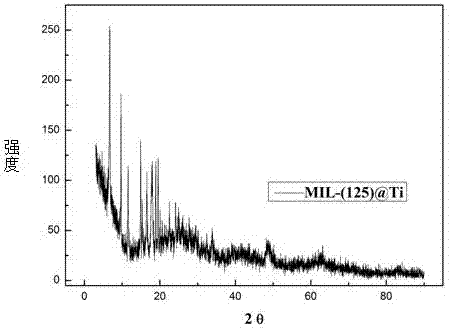

[0023] (2) Transfer the homogeneously mixed solution in (1) to a polytetrafluoroethylene-lined autoclave whose temperature has risen to 150°C, and keep it for 12 hours to obtain MOFs (MIL-125@Ti) .

[0024] (3) Suction filter the turbid liquid obtained from the reaction in (2), then vacuum-dry the obtained filter cake overnight at a temperature above 80 degrees Celsius, and finally grind the dried product with an agate mortar until it passes through a 300-mesh sieve.

[0025] (4) Calcinate the ground powder in (3) at 380°C for 4 hours in the air to...

Embodiment 2

[0029] (1) At room temperature, make a mixed solution of n-butyl titanate, formic acid, diaminoterephthalic acid and dimethylformamide in a molar ratio of 1:1.5:20:60, and mechanically stir and ultrasonically vibrate long enough for the medicines in it to mix well.

[0030] (2) Transfer the homogeneously mixed solution in (1) to a polytetrafluoroethylene-lined autoclave whose temperature has risen to 120 ° C, and keep it for 24 hours to obtain MOFs (MIL-125-NH 2 @Ti).

[0031] (3) Suction filter the turbid liquid obtained from the reaction in (2), then vacuum-dry the obtained filter cake overnight at a temperature above 80 degrees Celsius, and finally grind the dried product with an agate mortar until it passes through a 300-mesh sieve.

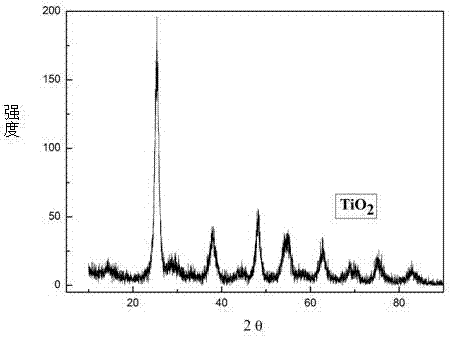

[0032] (4) Calcinate the ground powder in (3) at 480°C for 2 hours in the air to obtain porous titanium dioxide (TiO 2 ).

[0033] (5) The ground TiO in (4) 2 The powder and the lithium source are mixed well and evenly at a molar ratio of...

Embodiment 3

[0036] (1) At room temperature, make a mixed solution of isopropyl titanate, methanol, terephthalic acid and dimethylformamide in a molar ratio of 1:1.5:25:60, and mechanically stir and ultrasonically vibrate for a long enough time time to mix the medicines evenly.

[0037] (2) Transfer the homogeneously mixed solution in (1) to a polytetrafluoroethylene-lined autoclave whose temperature has risen to 120°C, and keep it for 36 hours to obtain MOFs (MIL-125@Ti) .

[0038] (3) Suction filter the turbid liquid obtained from the reaction in (2), then vacuum-dry the obtained filter cake overnight at a temperature above 80 degrees Celsius, and finally grind the dried product with an agate mortar until it passes through a 300-mesh sieve.

[0039] (4) Calcinate the ground powder in (3) at 580°C for 2 hours in the air to obtain porous titanium dioxide (TiO 2 ).

[0040] (5) The ground TiO in (4) 2 The powder and the lithium source are mixed well and evenly at a molar ratio of 0.8:1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

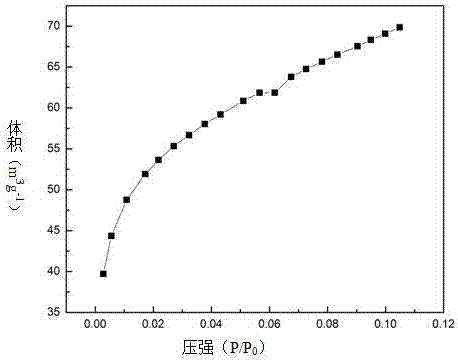

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com