Encapsulation method for optical fibre grating add-and-subtract quick strain sensor

A technology of strain sensor and optical fiber grating, which is applied in the field of sensing, can solve problems such as large difference between the sensitization coefficient and the theoretical value, a single way of increasing or decreasing sensitization, and difficult engineering applications, so as to avoid uneven bonding, simple structure, and eliminate effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

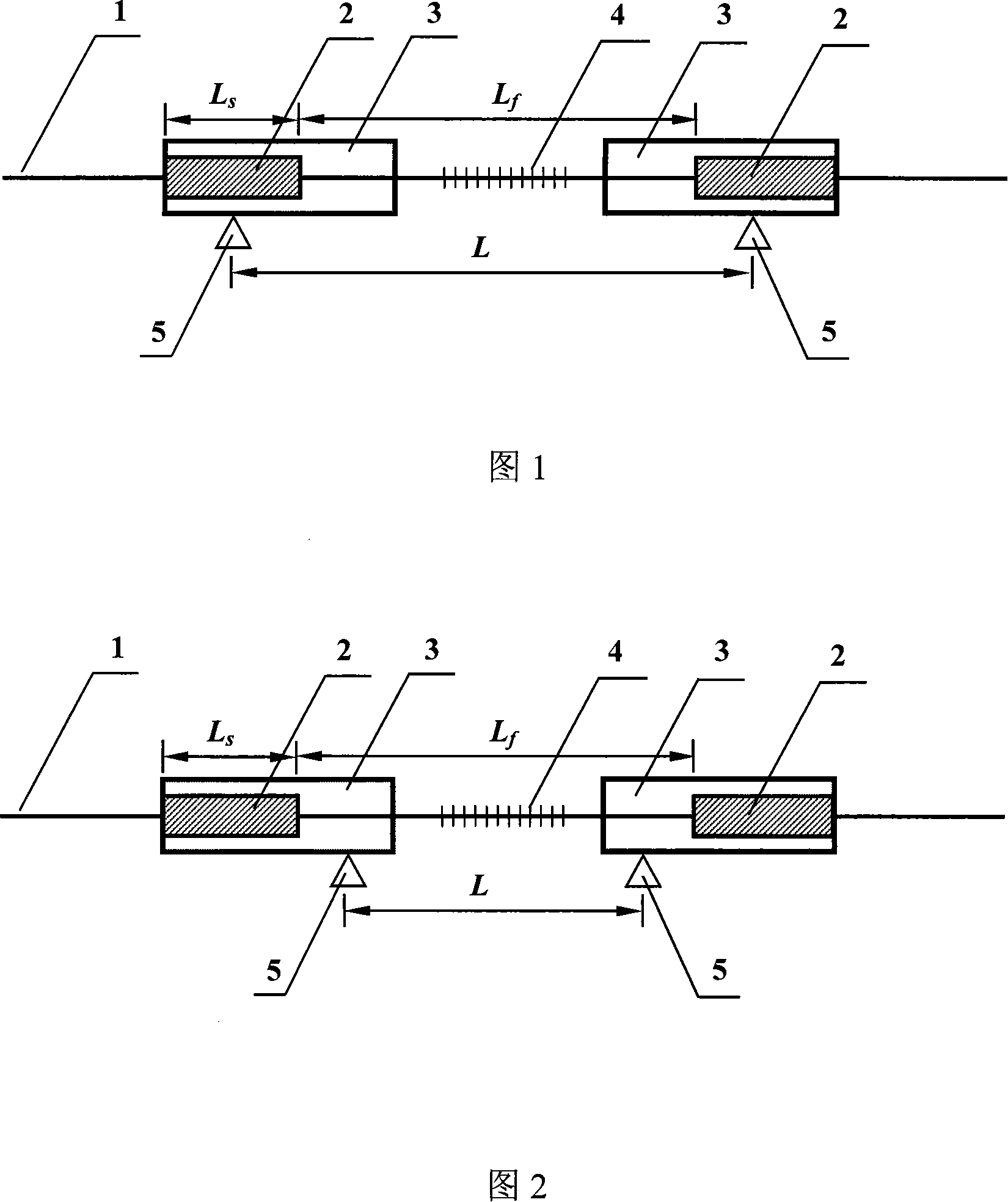

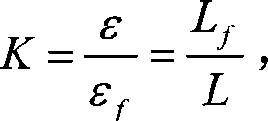

[0024] The schematic diagrams of the packaging structure of the fiber grating increase and decrease sensitive strain sensor proposed by the present invention are shown in accompanying drawings 1 and 2 . The specific method of packaging is to first peel off the coating layer on the surface of the optical fiber 1 at one end of the fiber grating 4, place the optical fiber 1 in the packaging component 2, and adjust its position with a precision optical fiber adjustment frame so that the stripped area of the optical fiber 1 is in the center , and then pour the adhesive to bond the optical fiber 1 in the packaging part 2. After the adhesive is cured, treat the optical fiber 1 and the packaging part 2 at the other end in the same way; then insert the two clamping parts 3 into the two ends of the fiber grating In the packaging par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com