Dynamic monitoring method and device of stress sensitization fiber bragg grating of locking rods of railway turnout switch machine

A technology of optical fiber grating and locking rod, which is applied in the measurement, transmission system, electrical components, etc. of the change force of the optical properties of the material when it is stressed, and can solve the problem that the light source of the lens and camera is easily polluted by dust and oil, etc. problems, to achieve high reliability, strong anti-interference ability, and good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

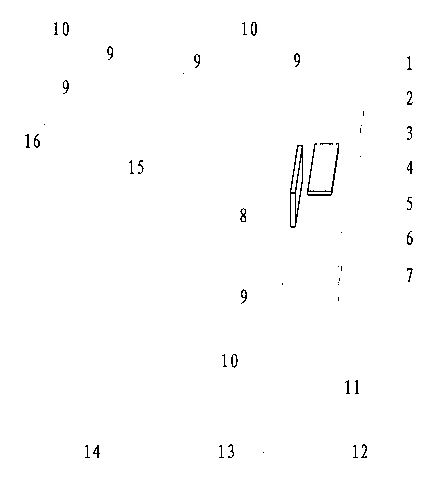

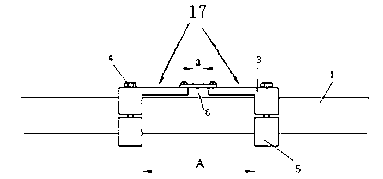

[0039] like figure 1 As shown, the present invention "Fiber Bragg Grating Dynamic Monitoring Method for Stress Sensitization of Locking Rod of Railway Turnout Switch Machine" uses fiber grating strain gauges to monitor the dynamic load of the locking rod.

[0040] The single locking lever stress detection device includes: switch machine locking lever 1 (for the detection target); a stainless steel protection box 2; two sets of strain-increased clamping devices (including two semicircular extended ) 3, four clamping block fixing bolts 4, two semicircular lower clamping blocks 5); a fiber grating strain gauge 6; four small screws 7; a fiber grating temperature compensation sheet 8.

[0041] The entire monitoring system also has: several transmission optical fibers 9; several optical fiber connection boxes 10; a multi-core armored optical cable 11; a demodulator 12; a data processing terminal 13; Two locking lever sensors 15 to be tested; the next locking lever sensor 16 to be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com