System for improving TSV etching process and etching endpoint monitoring method

An endpoint monitoring and process technology, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as short overlap time, misjudgment of plasma emission intensity, and inability to accurately detect endpoints, etc. Achieve effective monitoring, improve efficiency, extend weight and work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings of the specification. Of course, the present invention is not limited to this specific embodiment, and general replacements well known to those skilled in the art are also covered by the protection scope of the present invention.

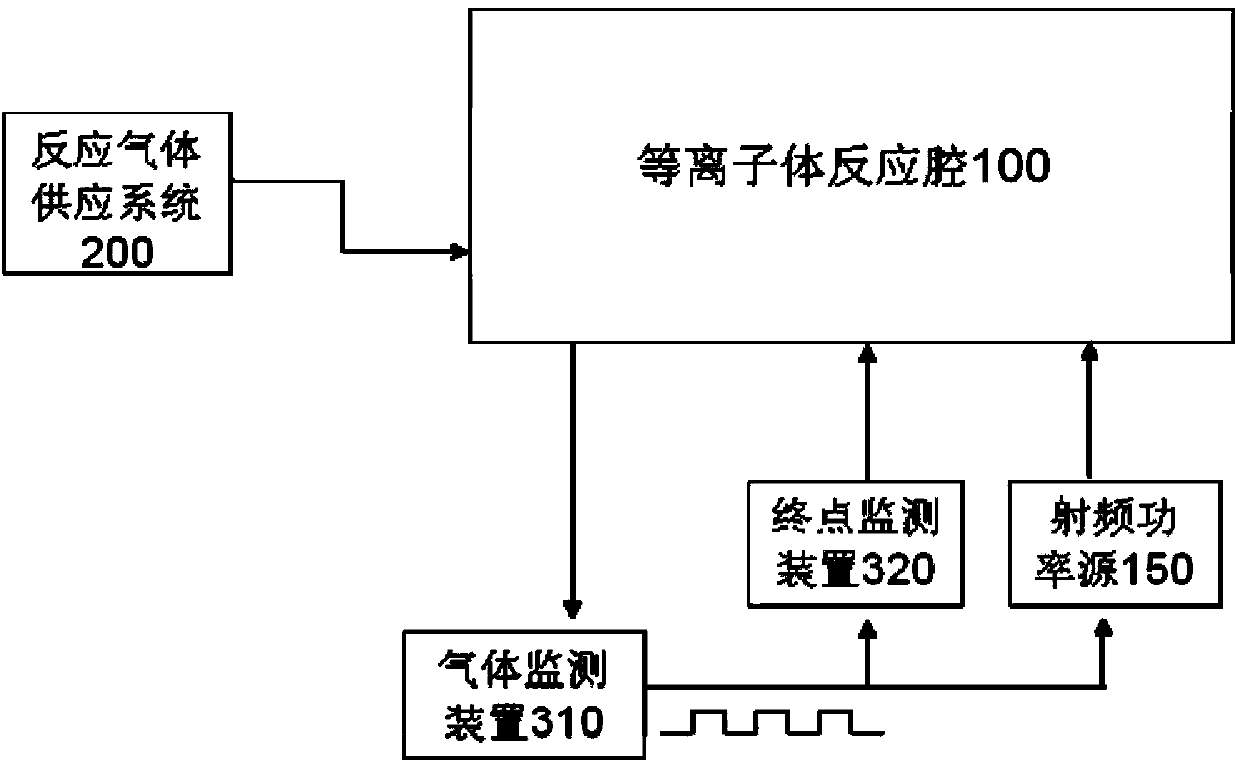

[0026] Such as figure 1 As shown, the present invention shows a system for improving the TSV etching process, including a plasma reaction chamber 100, the plasma reaction chamber 100 is connected to a reaction gas supply system 200 and a radio frequency power source 150, and the plasma reaction chamber 100 is also connected to a The gas monitoring device 310 and an endpoint monitoring device 320 are connected to the RF power source 150 and the endpoint monitoring device 320 and transmit synchronization signals to the RF power source 150 and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com