Non-dispersive infrared light gas detection system

A gas detection system and infrared light technology, which is applied in the field of non-separation infrared light gas sensors, can solve the problems of low detection accuracy, poor stability, and poor real-time performance, and achieve the effects of high precision, small drift, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

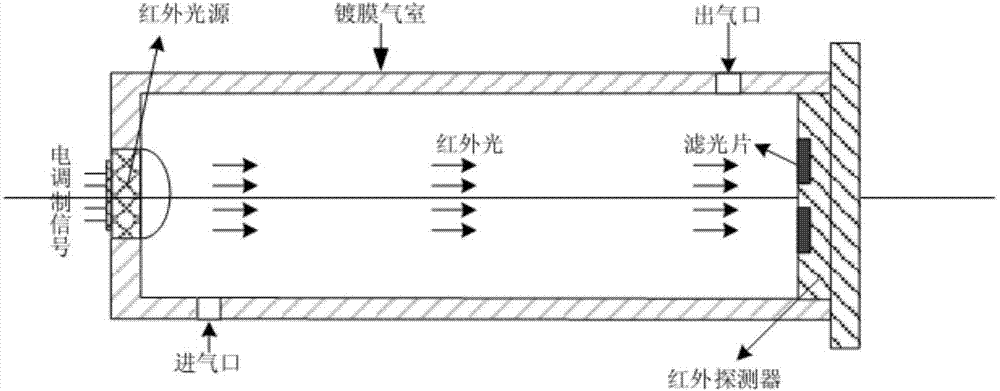

[0027] figure 1 It is a schematic diagram of the structure of the sampling gas chamber of the non-separation infrared light gas detection system of the present invention. In the figure, the electrical modulation signal and infrared light source provide infrared light of a single wavelength for gas detection; the inner wall of the coated gas chamber is made of gold-plated quartz glass tube material, which minimizes the loss of infrared light during propagation and increases corrosion resistance; The upper and lower air holes realize the circulation of the detection gas in the coating gas chamber; the infrared light passes through the filter to reach the infrared detector, and the infrared detector realizes the detection of the infrared light intensity after the gas absorption, and outputs the corresponding voltage according to the light intensity Signal.

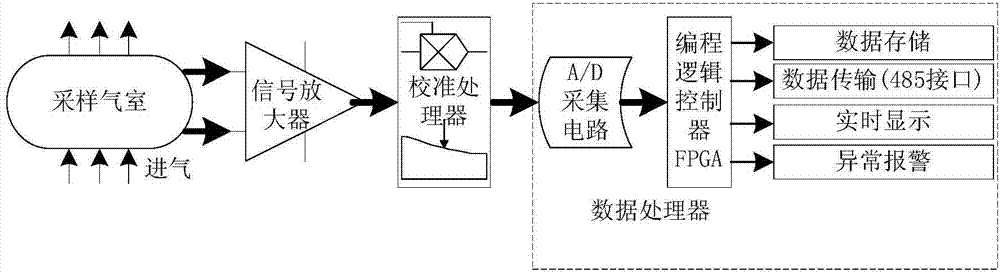

[0028] figure 2 It is a diagram of the working principle of the non-separation infrared light gas detection system of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com