Large-strain rolling method for alloy or metal matrix composite wide thin plates

An aluminum-based composite material and a composite material technology, applied in the field of alloy or metal-based composite material forming and control, can solve the problem of limiting the application range of alloy or metal-based composite material wide sheet, reducing sheet elongation performance, and affecting production efficiency. and other problems, to achieve the effect of not increasing the preparation cost, saving energy consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The silicon carbide particle reinforced aluminum matrix composite material is used to roll a wide sheet, and the preparation process is as follows:

[0053] a. Using spray deposition rapid solidification technology to prepare silicon carbide particle-reinforced aluminum matrix composite material into an ingot;

[0054] b. Hot extruding the ingot into a plate with a thickness of 10 mm;

[0055] c. Heat the plate to 440-470°C, and roll the plate with a pass reduction of 10%;

[0056] d, repeat the heating and rolling process of step c until the plate thickness is 4mm;

[0057] e. The plate obtained in step d is continuously rolled to a thickness of 0.75mm at a pass reduction of 50%, without heat treatment between passes.

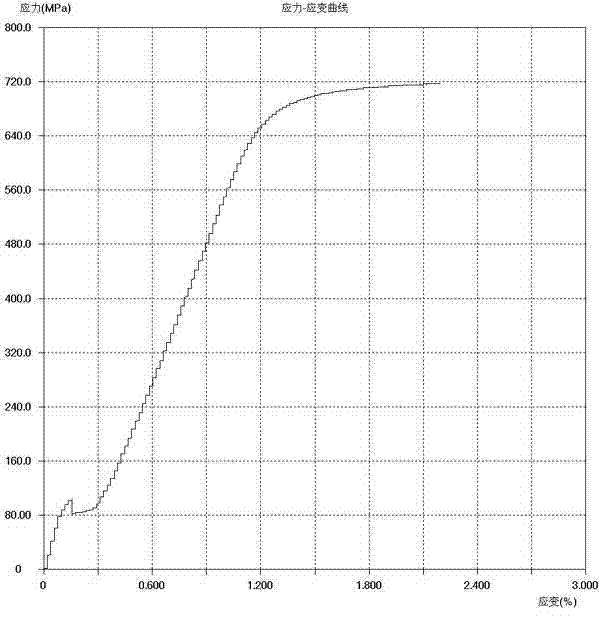

[0058] Depend on figure 1 It can be seen that the wide sheet of SiCp / 7075Al composite material prepared by the process of this embodiment is broken at 720 MPa, and the tensile strength reaches 720 MPa, which has good physical properties.

Embodiment 2

[0060] Titanium carbide particle-reinforced aluminum matrix composites are used, and the preparation process is as follows:

[0061] a. Using powder metallurgy technology to prepare titanium carbide particle-reinforced aluminum matrix composite material into an ingot;

[0062] b. Hot extruding the ingot into a plate with a thickness of 12 mm;

[0063] c. Heat the plate to 380-420°C, and roll the plate with a pass reduction of 8%;

[0064] d, repeat the heating and rolling process of step c until the plate thickness is 3mm;

[0065] e. The plate obtained in step d is continuously rolled to a thickness of 0.8mm at a pass reduction of 40%, without heat treatment between passes.

Embodiment 3

[0067] Using 5083Al aluminum alloy, the preparation process is as follows:

[0068] a. The 5083Al aluminum alloy is prepared into an ingot by casting technology;

[0069] b. Hot extruding the ingot into a plate with a thickness of 8 mm;

[0070] c. Heat the plate to 300-360°C, and roll the plate with a pass reduction of 5%;

[0071] d, repeat the heating and rolling process of step c until the plate thickness is 2mm;

[0072] e. The plate obtained in step d is continuously rolled to a thickness of 0.5 mm with a pass reduction of 30%, without heat treatment between passes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com