2D force transducer in small measurement range

A technology of force sensor and small range, which is applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc. It can solve the problems of complex processing, small overall stiffness of elastic bodies, and small measurement range, so as to achieve high overall stiffness and safety. The effect of high performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and example the present invention will be further described:

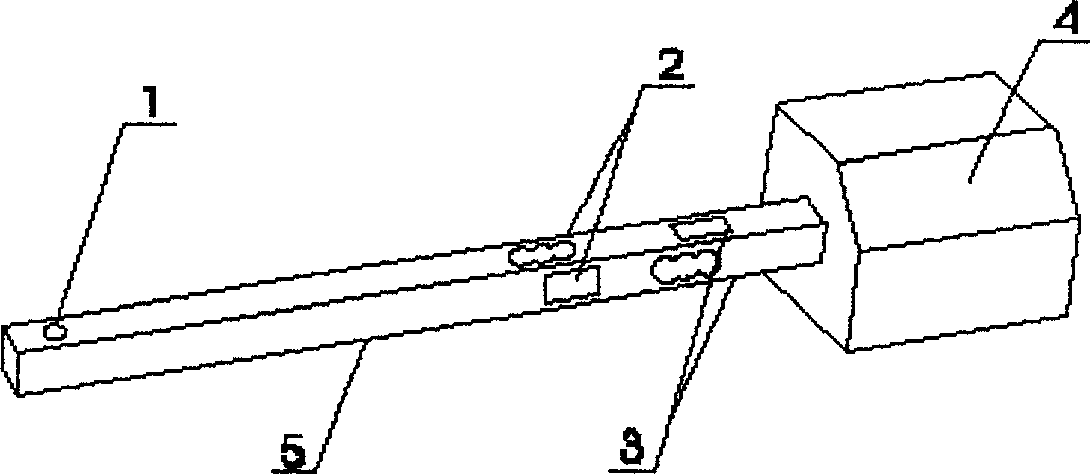

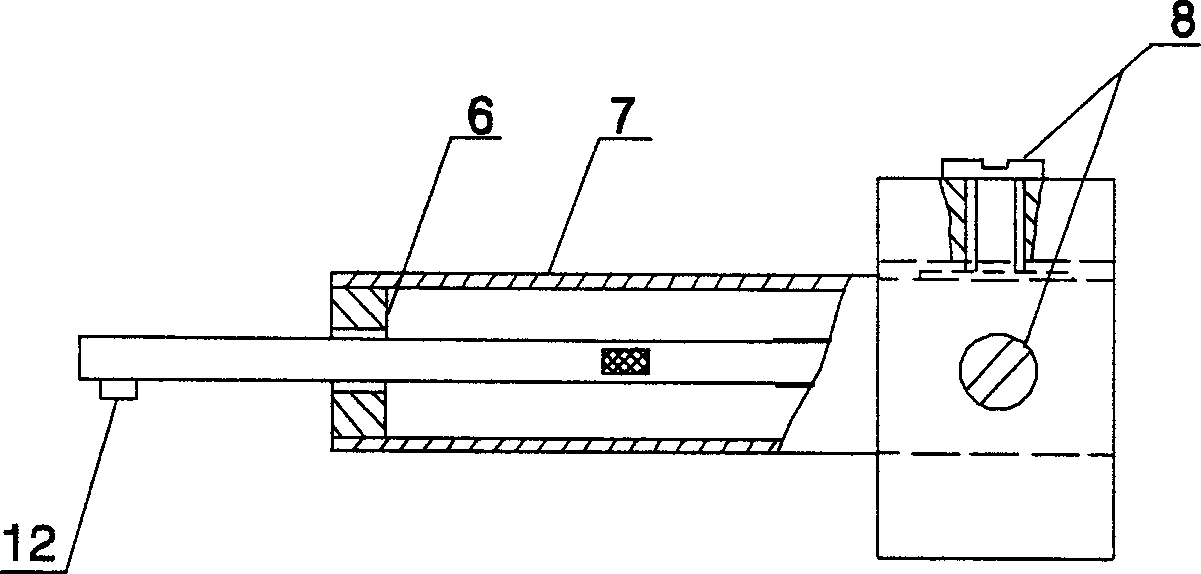

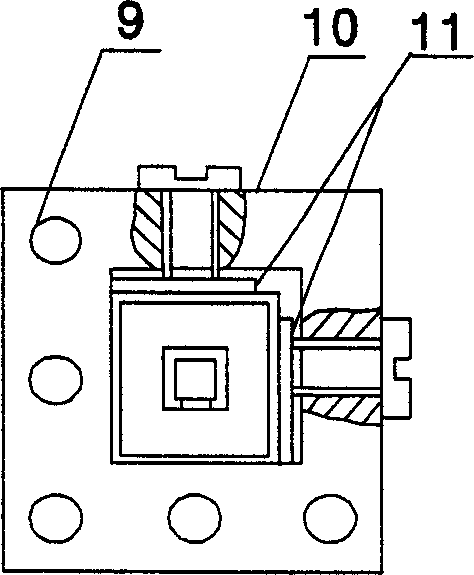

[0014] The elastic body of the two-dimensional small-range sensor of the present invention adopts a parallel beam structure, and holes are dug on the beam by using the principle of stress concentration to increase the overall rigidity of the elastic body. Such as figure 1 , 2 , The through hole 1 at the front end of the elastomer is used for clamping with the upper sample 12 . Two pairs of strain gauges, the front and rear pair of strain gauges 2 and the upper and lower pair of strain gauges 3, are respectively pasted on the outer surface of the front and rear holes and the outer surface of the upper and lower holes at the digging place of the elastic body cantilever 5, and the horizontal The front and rear strain gauges 2 for force testing and the upper and lower strain gauges 3 for vertical force testing, and two pairs of strain gauges form two sets of half-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com