Process for preparing modified concavo-convex bar soil of cation surface activating agent

A technology of modifying attapulgite and surfactant, which is applied in dyeing low molecular organic compound treatment, fibrous filler, etc., to achieve the effects of reducing adsorption capacity, increasing removal rate, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1. The impact of the kind of cationic surfactant on adsorption performance

[0022] Add 50ml of water to each of the four beakers, and number them sequentially 2-5, then add octadecyltrimethylammonium chloride, cetyltrimethylammonium chloride, cetyltrimethylammonium Methyl ammonium bromide, dodecyl trimethyl ammonium chloride, dodecyl dimethyl benzyl ammonium chloride, stirring with a glass rod to make it completely dissolved, then add 5g of the pretreated concave-convex to each beaker The bar clay was ultrasonically treated with a screen current of 0.6A for 5 minutes to prepare four parts of organically modified attapulgite clay, which were dried and crushed for use. Determination of the removal rate of phenol. And measure the removal rate of phenol by the attapulgite without organic modification, the number is 1, compare the adsorption performance, the results are shown in Table 1:

[0023] acid treatment

octadecyltrimethyl chloride

...

Embodiment 2

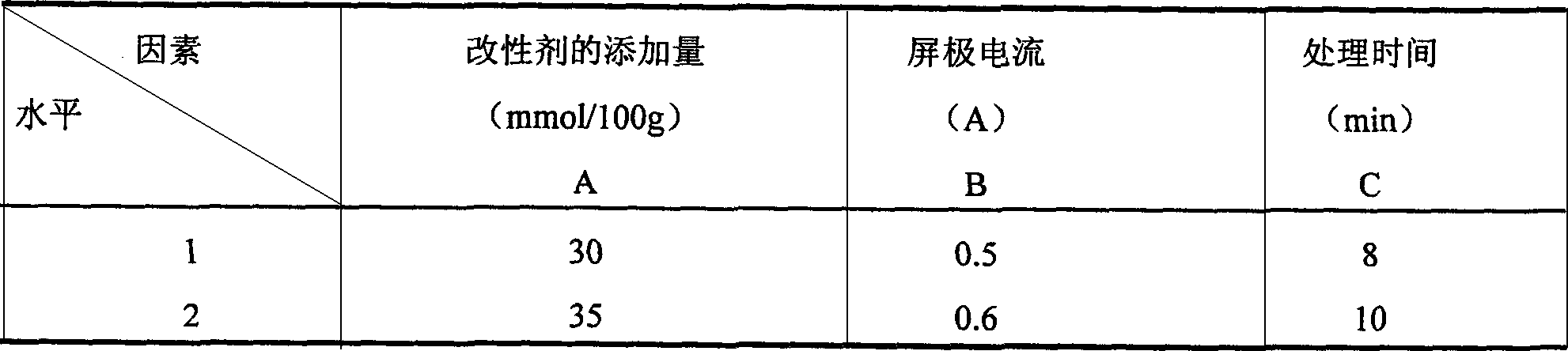

[0026] Embodiment 2. Determination of cationic surfactant modified attapulgite process conditions

[0027] Influence of Addition Amount of Cationic Surfactant on Adsorption Performance

[0028] Weigh octadecyltrimethylammonium chloride in proportions of 5mmol / 100g, 20mmol / 100g, 30mmol / 100g, 40mmol / 100g, 50mmol / 100g, and 70mmol / 100g, and add to six beakers filled with 50ml of water , stir the glass rod to make it completely dissolve, add 5g of pretreated attapulgite to each beaker, and use a 0.6A screen current for ultrasonic treatment for 5 minutes to prepare six kinds of organically modified attapulgite. Dried and crushed. Finally, the absorbance value was measured to calculate the removal rate of phenol.

[0029]The results show that the more the addition of octadecyl trimethyl ammonium chloride, the more obvious the modification effect of attapulgite, and when the addition of octadecyl trimethyl ammonium chloride is less, the addition The change of the concentration has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com