Method for preparing silane coupler modified attapulgite

The technology of silane coupling agent and attapulgite is applied in the field of development and utilization of attapulgite to achieve the effect of good guiding, improving utilization value and utilization rate, and improving interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

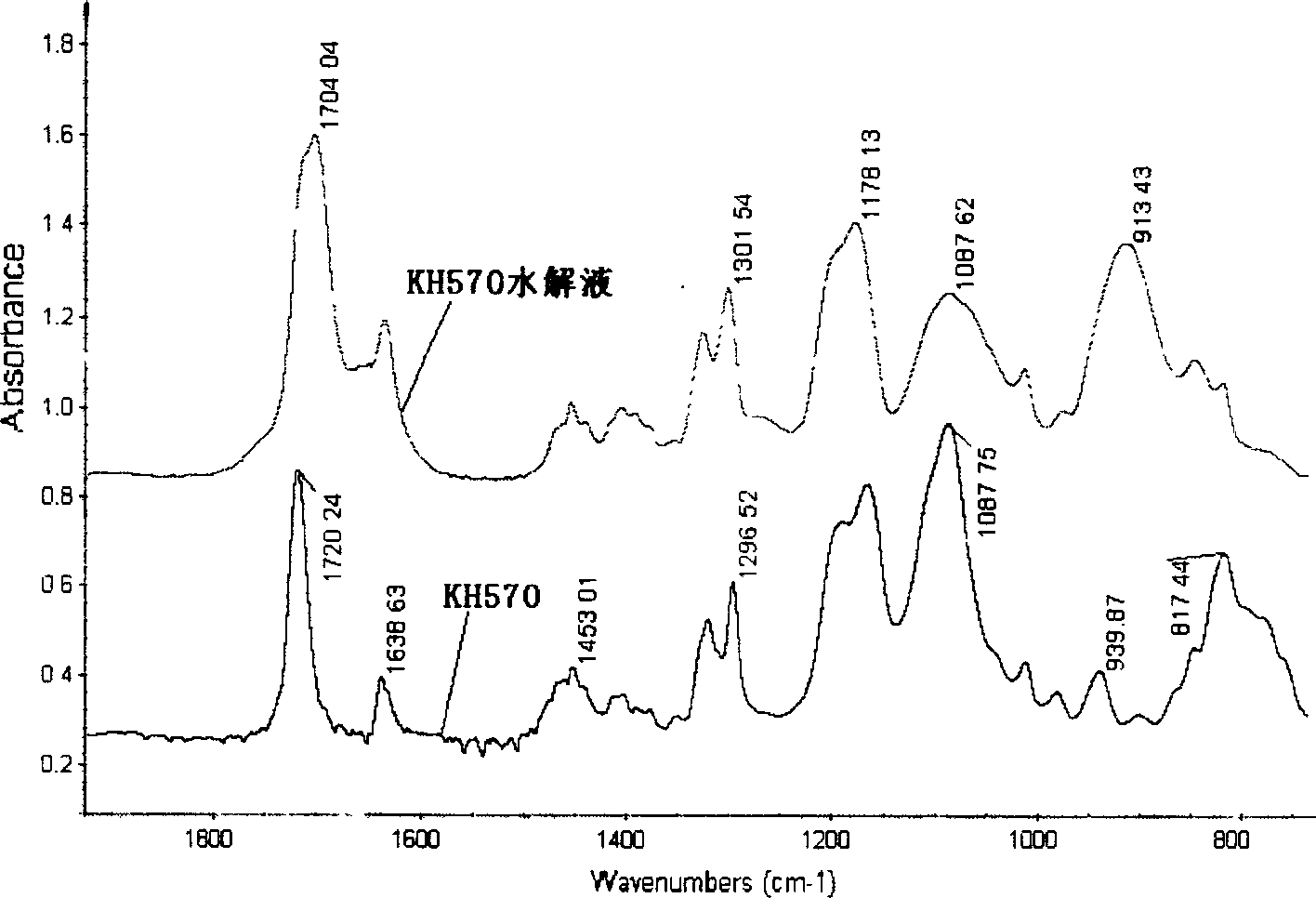

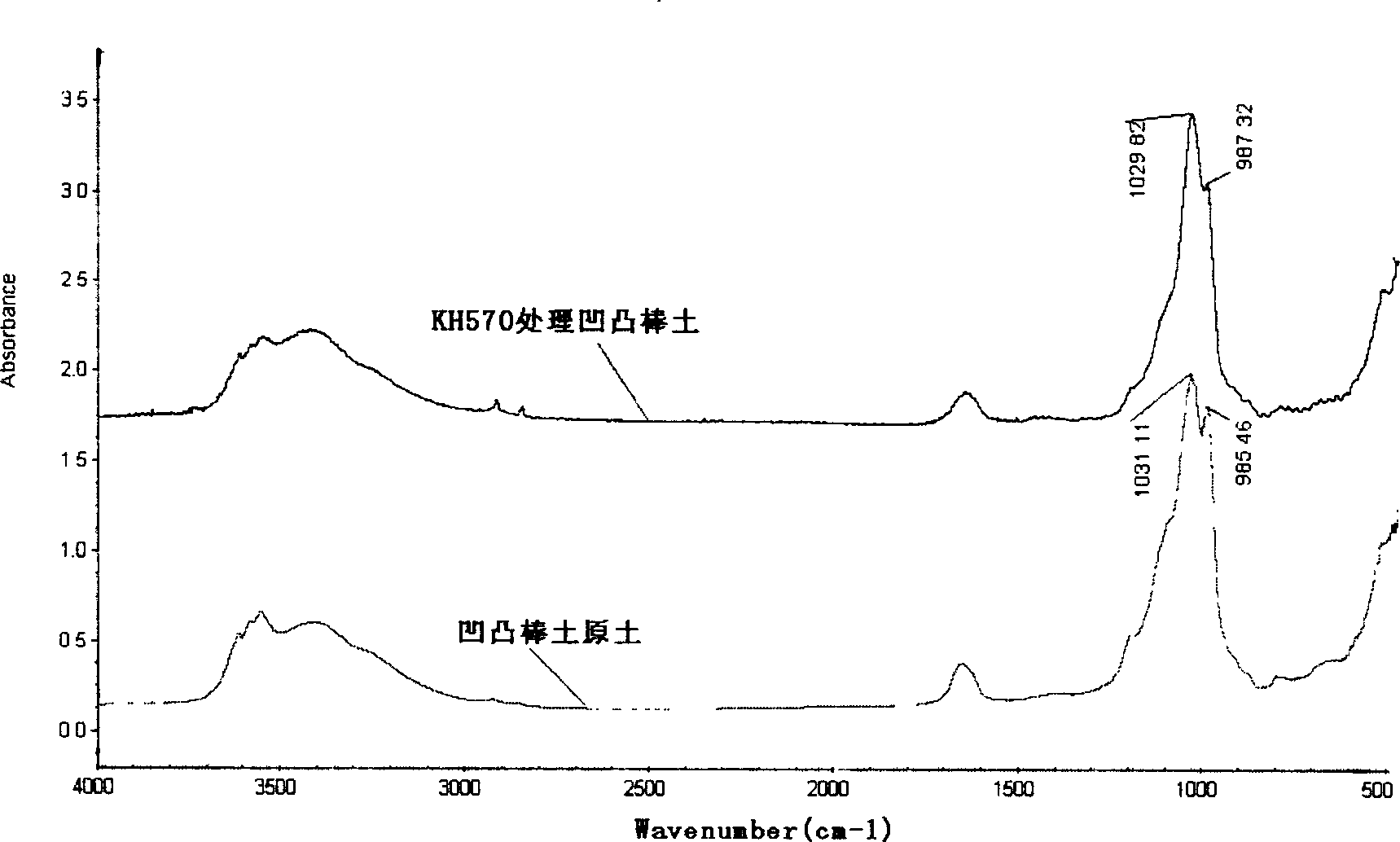

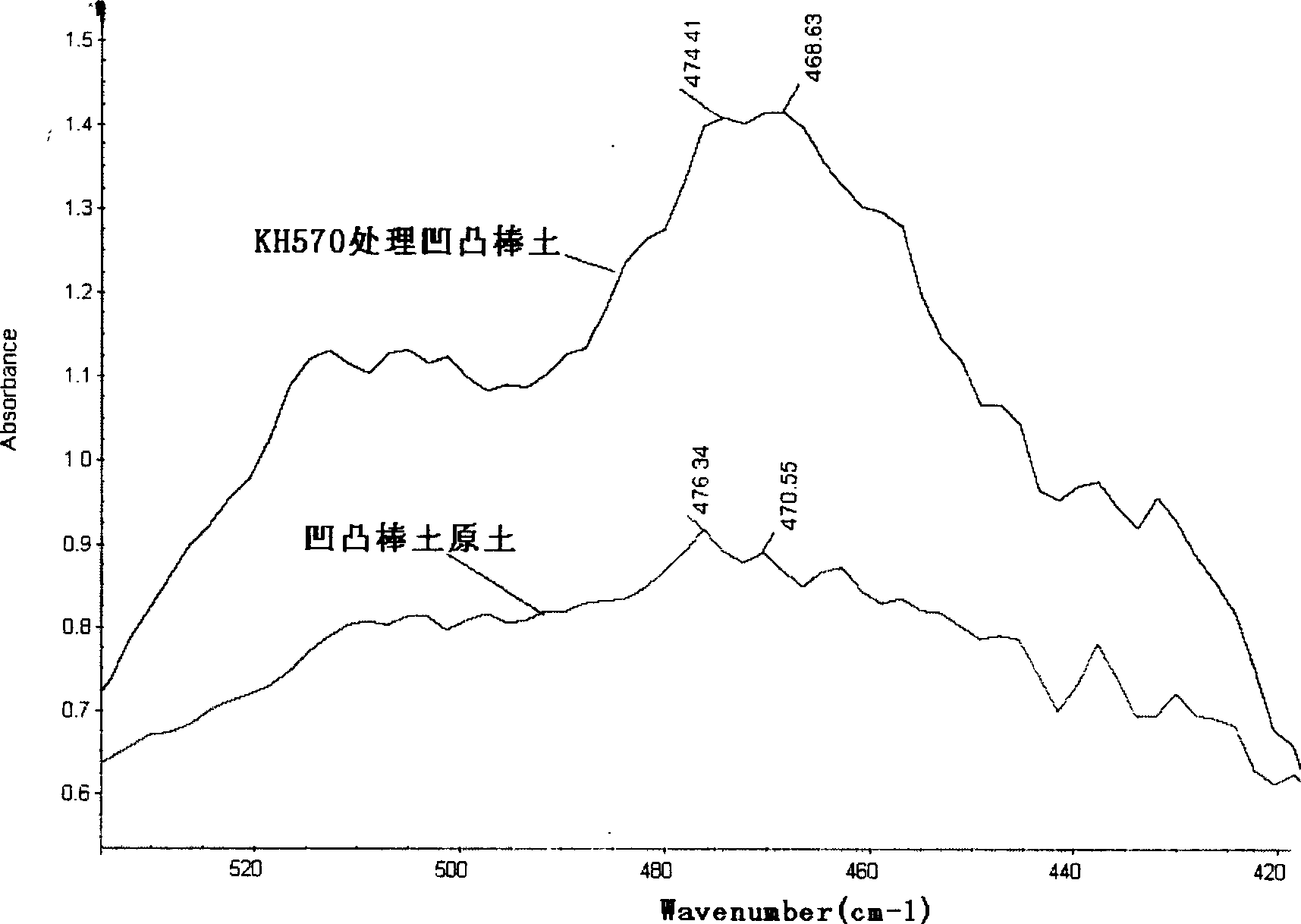

Image

Examples

Embodiment 1

[0030] The attapulgite used was raw ore of attapulgite collected from Xuyi, and the silane coupling agent was industrial grade KH570. The composition and content composition of attapulgite are shown in Table 1:

[0031] Element

MgO

Al 2 o 3

SiO 2

SO 2

K 2 o

CaO

TiO 2

MnO

Fe 2 o 3

Content (%)

8.2

11.9

63.8

1.0

1.9

1.6

1.4

0.5

9.7

[0032] (1) Acid treatment of attapulgite: 500 ml of 1 mol / l hydrochloric acid was added to 50 grams of attapulgite, stirred at 55°C for 60 minutes, then washed with deionized water to remove chloride ions, and then washed with 0.1 mol / l silver nitrate solution After detecting the absence of chloride ions, centrifugal dehydration, drying, and pulverization.

[0033] (2) Ultrasonic dispersion of attapulgite: Add 100 g of attapulgite to 200 ml of solution, and ultrasonically disperse for 10 minutes, in two steps of 5 minutes each time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com