Nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and preparation method and application thereof

A bifunctional catalyst, nitrogen-doped carbon technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor stability and self-aggregation, achieve good discharge performance, improve resistance Effects of CO poisoning and enrichment of active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

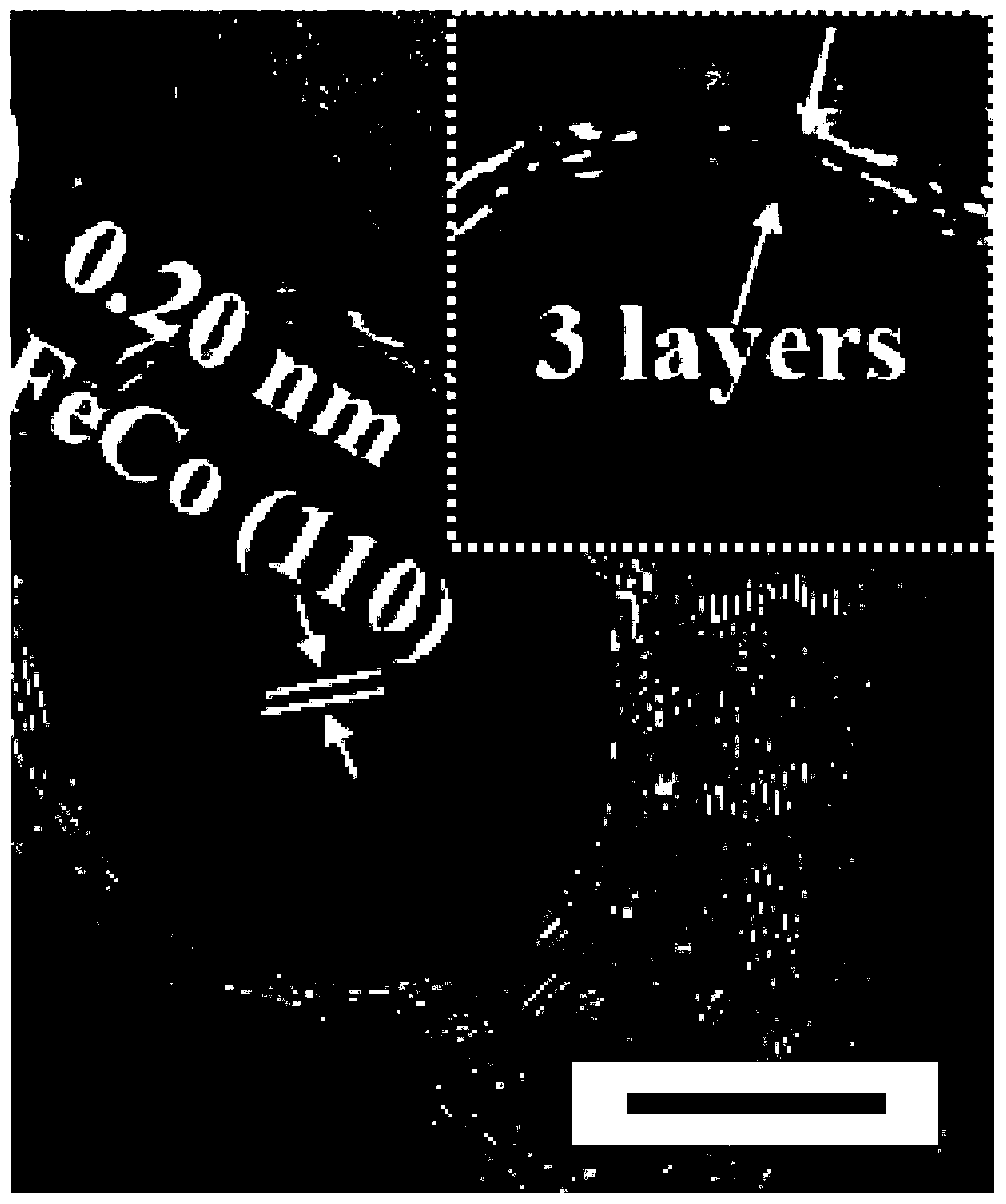

[0033] Example 1: Nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst supported by nitrogen-doped carbon nanotubes (Fe 1.2 Co@NC / NCNTs) synthesis:

[0034] (1) Pretreatment of carbon nanotubes:

[0035] Dissolve 100 mg of carbon nanotubes (CNTs) in 10 mL of acetone, stir at room temperature for 3 h, wash and dry; add the dried CNTs into the flask, and then add 100 mL of 10% HNO with a volume ratio of 2:1 3 and 10%H 2 o 2 Mixed solution, start stirring, heat up to 60°C, reflux and stir for 5h, suction filter after cooling, wash the filter cake with deionized water until neutral, dry in a vacuum oven at 50°C to constant weight, and dry the functional The NaCNTs samples were ground for later use.

[0036] (2) Grafting reaction of iron-cobalt organic ligands and melamine on the surface of functionalized carbon nanotubes:

[0037] Under the condition of stirring, 50 mg of FePc (ferric phthalocyanine) and 50 mg of CoPc (cobalt phthalocyanine) were ultrasonicall...

Embodiment 2

[0064] Example 2: Nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst supported by nitrogen-doped carbon nanotubes (Fe 2.8 Co@NC / NCNTs) synthesis:

[0065] (1) Pretreatment of carbon nanotubes:

[0066] Dissolve 200 mg of carbon nanotubes (CNTs) in 10 mL of acetone, stir at room temperature for 5 h, wash and dry; add the dried CNTs into the flask, and then add 100 mL of 10% HNO with a volume ratio of 3:1 3 and 35%H 2 o 2 Mixed liquid, start stirring, heat up to 80°C, reflux and stir for 5h, suction filter after cooling, wash the filter cake with deionized water until neutral, dry in a vacuum oven at 80°C to constant weight, and dry the functional The NaCNTs samples were ground for later use.

[0067] (2) Grafting reaction of iron-cobalt organic ligands and melamine on the surface of functionalized carbon nanotubes:

[0068] Under the condition of stirring, 100 mg of FePc (ferric phthalocyanide) and 30 mg of CoPc (cobalt phthalocyanine) materials were ultr...

Embodiment 3

[0073] Example 3: Nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst supported by nitrogen-doped carbon nanotubes (FeCo 2.5 @NC / NCNTs) synthesis:

[0074] (1) Pretreatment of carbon nanotubes:

[0075] Dissolve 50 mg of carbon nanotubes (CNTs) in 5 mL of acetone, stir at room temperature for 3 h, wash and dry; add the dried CNTs into the flask, and then add 50 mL of 5% HNO with a volume ratio of 2:1 3 and 10%H 2 o 2 Mixed solution, start stirring, heat up to 60°C, reflux and stir for 3h, suction filter after cooling, wash the filter cake with deionized water until neutral, dry in a vacuum oven at 50°C to constant weight, and dry the functional The NaCNTs samples were ground for later use.

[0076] (2) Grafting reaction of iron-cobalt organic ligands and melamine on the surface of functionalized carbon nanotubes:

[0077] Under the condition of stirring, 30mg of FePc (ferric phthalocyanine) and 100mg of CoPc (cobalt phthalocyanine) materials were ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com