Aqueous permeable concrete sealing and curing agent

A sealing curing agent and permeable technology, used in the field of building materials, can solve the problems of ash and sand, low strength and wear resistance of concrete floors, improve strength, improve impermeability and fouling resistance, and avoid ash. sand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

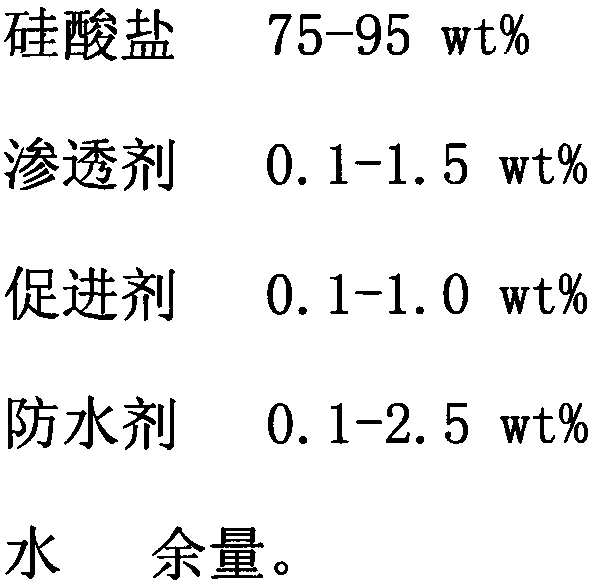

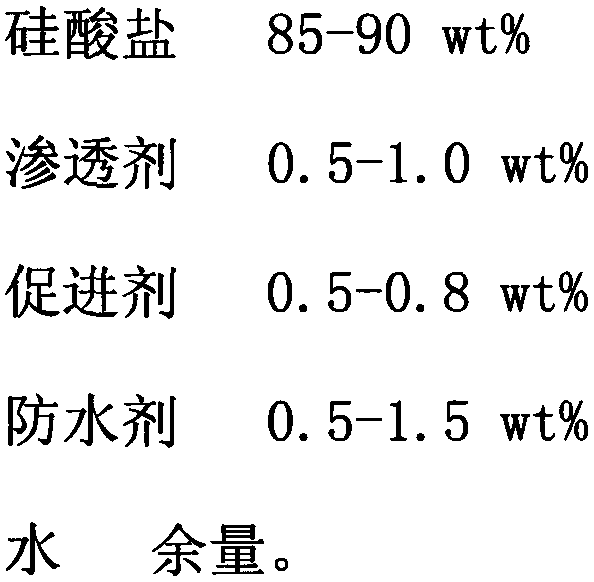

Method used

Image

Examples

Embodiment 1

[0023] In the water-based permeable concrete sealing and curing agent of the present invention, silicate is the main component, and the silicate is sodium silicate, accounting for 90% by weight; the penetrating agent accounts for 0.5% by weight, and the penetrating agent adopts dodecyl sulfonate Accelerator accounts for 0.5% by weight, and the accelerator adopts organic amines; the waterproof agent accounts for 0.8% by weight, and the waterproof agent adopts octyltriethoxysilane aqueous emulsion; water is the balance, accounting for 8.2% by weight .

[0024] The water-based sealing and curing agent is diluted with water at 1:4, coated and soaked on the concrete surface, and after 4 hours, the residual material is removed, dried in the air, finely ground and polished. After treatment, the wear resistance, impermeability and stain resistance, and gloss of the concrete floor have been greatly improved.

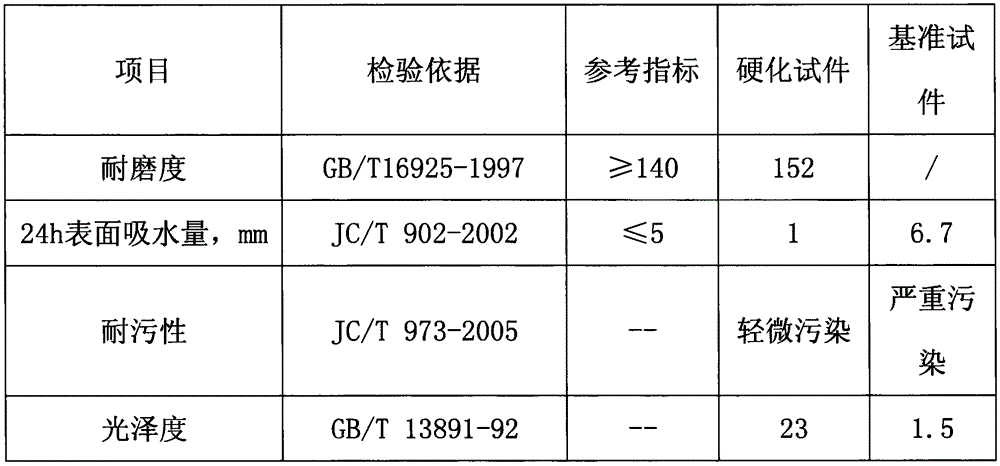

[0025] Table 1 shows the performance parameters of the concrete coated with...

Embodiment 2

[0029] In the water-based permeable concrete sealing and curing agent of the present invention, silicate is the main component, and the silicate is lithium silicate, accounting for 85% by weight; the penetrating agent accounts for 0.5% by weight, and the penetrating agent adopts fluorocarbon surfactant ; Accelerator accounts for 1.0% by weight, and sulfate is used as the accelerator; Water repellent accounts for 1.0% by weight, and methyl silicate is used for water repellent; Water is the balance, accounting for 12.5% by weight.

[0030] The water-based sealing and curing agent is diluted with water at 1:4, coated and soaked on the concrete surface, and after 4 hours, the residual material is removed, dried in the air, finely ground and polished. After treatment, the wear resistance, impermeability and stain resistance, and gloss of the concrete floor have been greatly improved.

[0031] Table 2 shows the performance parameters of the concrete coated with the water-based per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com