Harmless treatment and comprehensive utilization method of silicon tetrachloride

A harmless treatment, silicon tetrachloride technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve separation difficulties, easy market saturation, and difficulty in meeting environmental protection discharge standards And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

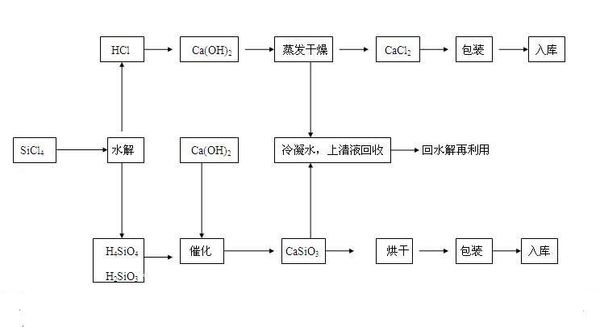

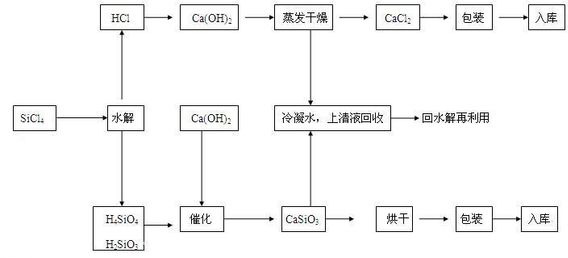

Image

Examples

Embodiment 1

[0028] A method for harmless treatment and comprehensive utilization of silicon tetrachloride, the specific process steps are as follows:

[0029] A. On the bottom and inner wall of the liquid storage tank generated by the hydrolysis reaction of silicon tetrachloride, paste nano-titanium dioxide immobilized catalyst tiles, the area is calculated as 3 square meters per cubic meter of liquid, and catalyze for 1 hour.

[0030] B. Add calcium hydroxide to the liquid after catalysis, and control the pH value at 8, that is, the reaction will generate calcium chloride and calcium silicate precipitation;

[0031] C. After the calcium chloride and calcium silicate precipitates generated in step B are separated by sedimentation, the calcium silicate precipitates are washed and dried to obtain hydrated calcium silicate, and the separated liquid is recovered and returned to the silicon tetrachloride hydrolysis process for reuse.

[0032] The preparation method of the nano-titanium dioxide...

Embodiment 2

[0035] A method for harmless treatment and comprehensive utilization of silicon tetrachloride, the specific process steps are as follows:

[0036] A. On the bottom and inner wall of the liquid storage tank generated by the hydrolysis reaction of silicon tetrachloride, paste nano-titanium dioxide immobilized catalyst tiles, the area is calculated as 5 square meters per cubic meter of liquid, and catalyze for 2 hours.

[0037] B. Add calcium hydroxide to the liquid after catalysis, and control the pH value at 9, that is, the reaction will generate calcium chloride and calcium silicate precipitation;

[0038] C. After the calcium chloride and calcium silicate precipitates generated in step B are separated by sedimentation, the calcium silicate precipitates are washed and dried to produce hydrated calcium silicate, and the separated liquid is recovered and returned to the silicon tetrachloride hydrolysis process for reuse.

[0039] The ceramic tiles are nano-titanium dioxide immob...

Embodiment 3

[0043] A method for harmless treatment and comprehensive utilization of silicon tetrachloride, the specific process steps are as follows:

[0044] A. On the bottom and inner wall of the liquid storage tank generated by the hydrolysis reaction of silicon tetrachloride, paste nano-titanium dioxide immobilized catalyst tiles, the area is calculated as 4 square meters per cubic meter of liquid, and catalyze for 3 hours.

[0045] B. Add calcium hydroxide to the liquid after catalysis, and the pH value is controlled at 10, that is, the reaction generates calcium chloride and calcium silicate precipitation;

[0046] C. After the calcium chloride and calcium silicate precipitates generated in step B are separated by sedimentation, the calcium silicate precipitates are washed and dried to produce hydrated calcium silicate, and the separated liquid is recovered and returned to the silicon tetrachloride hydrolysis process for reuse.

[0047] The ceramic tiles are nano-titanium dioxide immo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com