Calcium silicate hydrate gel solution early strength agent and preparation method thereof

A technology of hydrated calcium silicate and gel solution, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of complex preparation process, poor early strength effect, difficult storage, etc. The effect of increased pressure strength and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A calcium silicate hydrate (C-S-H) gel solution accelerator, its raw materials include: calcareous material, siliceous material, gel dispersant and water, wherein the molar ratio of calcium material and siliceous material is 0.3 ~3:1, the weight ratio of water to the total weight of calcareous material and siliceous material is 5~30:1, and the mass fraction of gel dispersant is 0.1%~2.0%.

[0025] Specifically, for the convenience of obtaining materials, the siliceous material is sodium silicate powder, and the calcium material is calcium nitrate crystal. Calculate sodium silicate powder, calcium nitrate crystal and The amount of water used, and accurately weighed for later use. Considering that the calcium silicate hydrate solution used as an early strength agent is in a flocculent gel state, it will precipitate and stratify under the action of water absorption and its own gravity, resulting in poor stability of the calcium silicate hydrate solution and affecting the ...

Embodiment 2

[0027] The raw material of calcium silicate hydrate gel solution early strength agent is: the molar ratio of calcium material and siliceous material is 1:1, the weight ratio of water to the total weight of calcium material and siliceous material is 8:1, The mass fraction of the gel dispersant is 0.50%. At this time, when preparing the calcium silicate hydrate gel solution, the aqueous solution of sodium silicate and the aqueous solution of calcium nitrate need to be stirred for 30 seconds respectively. Moreover, when the aqueous solution of sodium silicate reacts with the aqueous solution of calcium nitrate, it needs to be stirred for 180s. Finally, the product obtained is milky white gel liquid, which is calcium silicate hydrate gel mixed solution. At this time, the mass fraction of calcium silicate hydrate in the calcium silicate hydrate gel mixed solution is about 3.7%.

Embodiment 3

[0029] The raw material of calcium silicate hydrate gel solution early strength agent is: the molar ratio of calcareous material to siliceous material is 0.8:1, the weight ratio of water to the total weight of calcium material and siliceous material is 12:1, The mass fraction of the gel dispersant is 1.00%. At this time, when preparing the calcium silicate hydrate gel solution, the aqueous solution of sodium silicate and the aqueous solution of calcium nitrate need to be stirred for 35 seconds respectively. Moreover, when the aqueous solution of sodium silicate reacts with the aqueous solution of calcium nitrate, it needs to be stirred for 150s. Finally, the product obtained is milky white gel liquid, which is calcium silicate hydrate gel mixed solution. At this time, the mass fraction of calcium silicate hydrate in the calcium silicate hydrate gel mixed solution is about 2.6%.

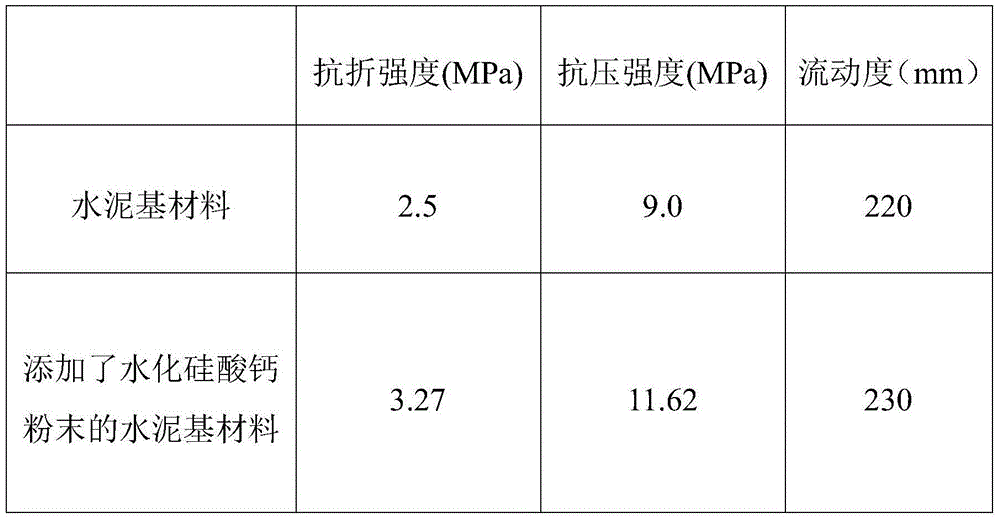

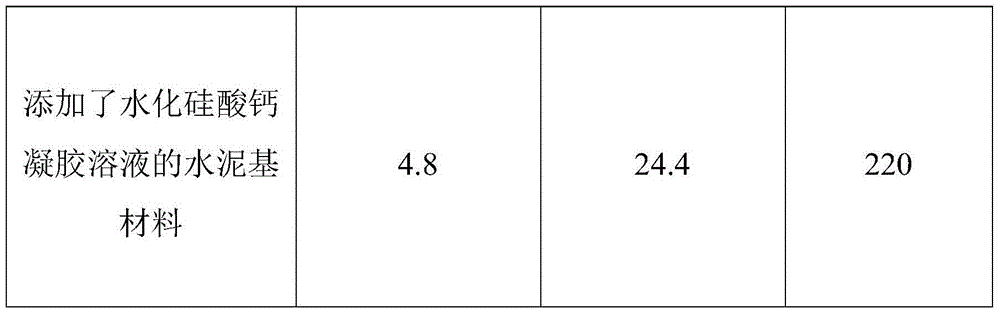

[0030] In particular, in order to facilitate the description of the early-strength effect of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com