Method for hydro-thermal preparation of hydroxyapatite powder by calcium silicate precursor

A technology of hydroxyapatite and calcium silicate, used in chemical instruments and methods, prostheses, phosphorus compounds, etc., can solve the problems of HAp powder morphology and chemical composition that are rarely reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare 0.5mol / L calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and sodium silicate (Na 2 SiO 3 9H 2 O) Aqueous solution. An equal volume of calcium nitrate aqueous solution was added dropwise to the sodium silicate aqueous solution with stirring. After the dropwise addition was complete, stirring was continued for 24 hours. After that, filter, wash and dry to obtain calcium silicate hydrate powder.

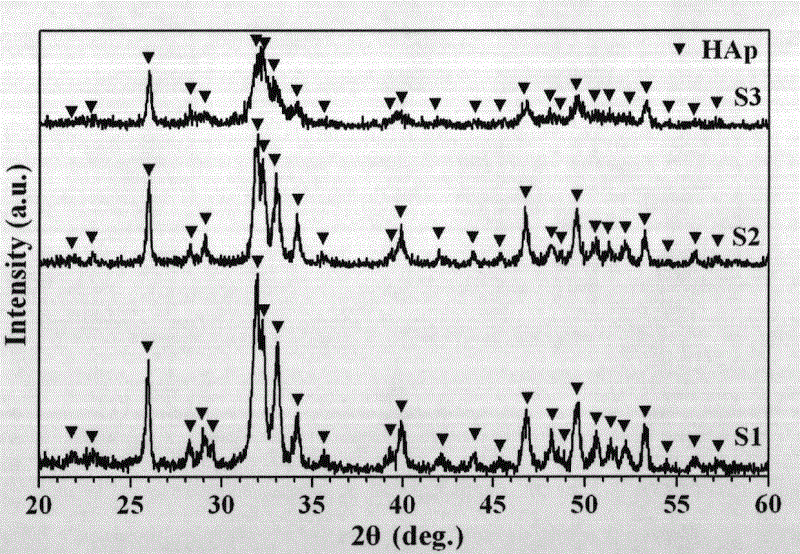

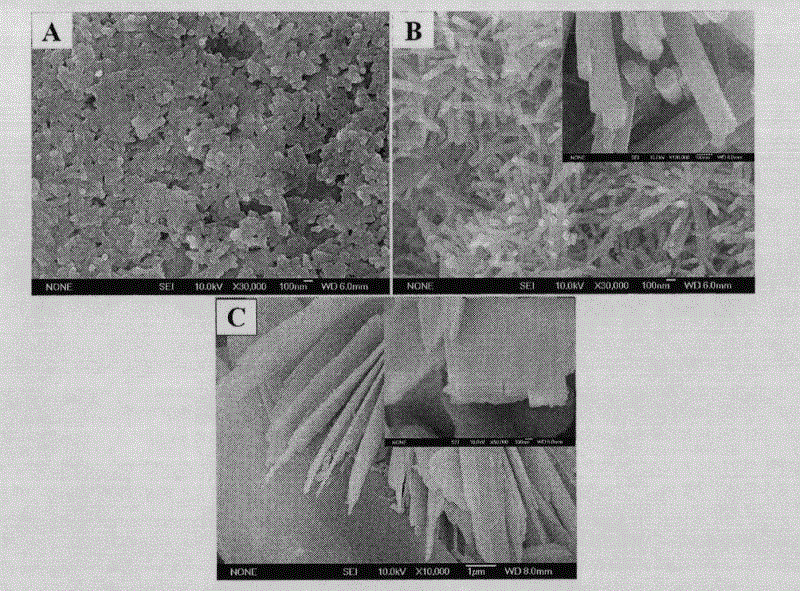

[0032] The prepared calcium silicate hydrate powder 1g and 85mL concentration are 0.2mol / L Na 3 PO 4 Mix the aqueous solution (the molar ratio of calcium to phosphorus is about 0.4), transfer to a 100mL reactor after mixing, and conduct hydrothermal treatment at 180°C for 24 hours. After the hydrothermal reaction, filter and wash to obtain the product. The X-ray diffraction pattern confirms that the product is pure hydroxyapatite powder (such as figure 1 Shown in S1); Scanning electron microscopy shows that the product is a nanoparticle, and the particle size is about 90 ...

Embodiment 2

[0034] The calcium silicate hydrate powder prepared in Example 1 was calcined at 800° C. for 2 hours to obtain calcium silicate powder. Mix 1 gram of calcined calcium silicate powder with 85 mL of 0.2 mol / L Na 3 PO 4 The aqueous solutions were mixed (the molar ratio of calcium to phosphorus was about 0.5), and after mixing, they were transferred to a 100mL reactor, and hydrothermally treated at 180°C for 24 hours. After the hydrothermal reaction, filter and wash to obtain the product. The X-ray diffraction pattern confirms that the product is pure hydroxyapatite powder (such as figure 1 Shown in S2); scanning electron microscopy shows that the product is a nanowire with a diameter of about 100 nanometers and a length of 2 microns (such as figure 2 shown in B). Chemical composition analysis showed that the mass percent contents of Na and Si in hydroxyapatite powder were 1.58% and 0.89%, respectively. It shows that the prepared product is hydroxyapatite powder doped with N...

Embodiment 3

[0036] The calcium silicate hydrate powder prepared in Example 1 was calcined at 800° C. for 2 hours to obtain calcium silicate powder. Mix 1 gram of calcined calcium silicate powder with 85 mL of NaH with a concentration of 0.2 mol / L 2 PO 4 The aqueous solutions were mixed (the molar ratio of calcium to phosphorus was about 0.5), and after mixing, they were transferred to a 100mL reactor, and hydrothermally treated at 180°C for 24 hours. After the hydrothermal reaction, filter and wash to obtain the product. The X-ray diffraction pattern confirms that the product is pure hydroxyapatite powder (such as figure 1 Shown in S3); Scanning electron microscopy shows that the product is a nanosheet, the thickness of the nanosheet is about 100 nanometers, the width is about 1-2 microns, and the length can reach 20 microns (such as figure 2 C shown). Chemical composition analysis showed that the mass percent contents of Na and Si in hydroxyapatite powder were 1.47% and 0.94%, respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com