High-RAP-content asphalt mixture formula and preparation method

A technology of asphalt mixture and manufacturing method, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of unstable molecular structure and arrangement of chemical components, low temperature performance of recycled asphalt mixture and Poor water stability, failure to meet the requirements of low temperature performance and water stability, etc., to achieve the effect of compact structure, increasing the amount of asphalt, and improving water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of asphalt mixture formula with high content of RAP, the mass percentage of its components is as follows:

[0031] 45% milling old material;

[0032] 48.3% aggregates, aggregates include coarse aggregates and fine aggregates, coarse aggregates are made of crushed stones, crushed gravel, and steel slag, and fine aggregates are made of natural sand, machine-made sand, and stone chips.

[0033] 1.5% mineral powder, the mineral powder is finely ground from strong basic rock in limestone or igneous rock.

[0034] 1.5% ordinary portland cement;

[0035] 0.3% of polyester fibers with a length of 6 mm;

[0036] 3.4% No. 90 base asphalt.

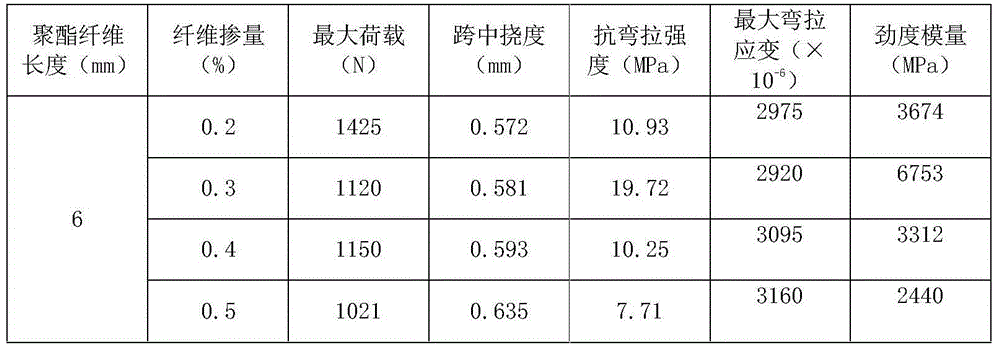

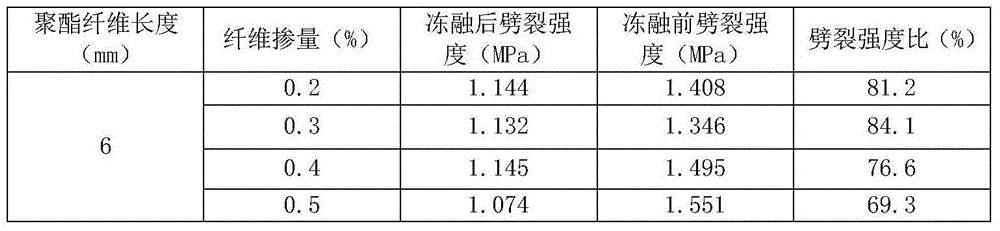

[0037] Experimental design: Design 4 test groups of recycled asphalt mixture. The main difference between these 4 test groups is that the amount of polyester fiber is 0.2%, 0.3%, 0.4%, and 0.5%.

[0038] The 0.3% test group is Example 1.

[0039] 0.2% The mass percentage of each component of the test group: 45% milling old material...

Embodiment 2

[0051] A kind of asphalt mixture formula with high content of RAP, its mass percentage is as follows:

[0052] 50% milling old material;

[0053] 43.3% of the aggregate, the aggregate includes coarse aggregate and fine aggregate, the coarse aggregate is composed of crushed stone, crushed gravel, and steel slag, and the fine aggregate is composed of natural sand, machine-made sand, and stone chips.

[0054] 1.5% mineral powder, the mineral powder is finely ground from strong basic rock in limestone or igneous rock.

[0055] 1.5% ordinary portland cement;

[0056] 0.3% of polyester fibers with a length of 6mm;

[0057] 3.4% No. 90 base asphalt.

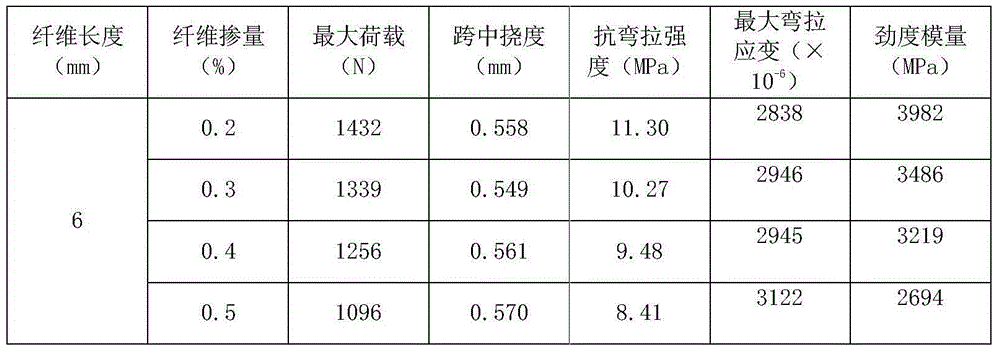

[0058] Experimental design: Design 4 test groups of recycled asphalt mixture. The difference between these 4 test groups is that the amount of polyester fiber is 0.2%, 0.3%, 0.4%, and 0.5%.

[0059] The 0.3% test group is Example 2.

[0060] 0.2% The mass percentage of each component of the test group: 50% old milling material; 43....

Embodiment 3

[0071] The manufacturing method of asphalt mixture with high RAP content, the steps are as follows:

[0072] (1) Preheat the old milling material at 110°C for 2 hours;

[0073] (2) Add the milling old material preheated in step (1) into the mixing pot, and the temperature of the mixing pot is 175°C;

[0074] (3) Then add the preheated aggregates into the mixing pot (the preheating temperature of the aggregates is 180°C, and the preheating time is 4 to 5 hours), and at the same time add polyester fibers with a length of 6mm, and mix for 90s;

[0075] (4) Add preheated No. 90 base asphalt (the preheating temperature of No. 90 base asphalt is 150-160°C), preheating time is 4-5 hours, and mixing for 90s;

[0076] (5) Add slag powder (the slag powder is ground from strong basic rock in limestone or magmatic rock, the preheating temperature is 180°C, and the preheating time is 4-5h) and mix for 90s.

[0077] The mass percent of each component of the asphalt mixture formula in embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com