Leaching repair system for heavy metal contaminated soil

A technology for polluted soil and remediation system, applied in heavy metal contaminated soil leaching and remediation system, heavy metal contaminated soil leaching and remediation field, can solve the problems of strong toxicity, long remediation period, easy to be absorbed by organisms, etc., to achieve strong removal ability and energy saving High efficiency and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

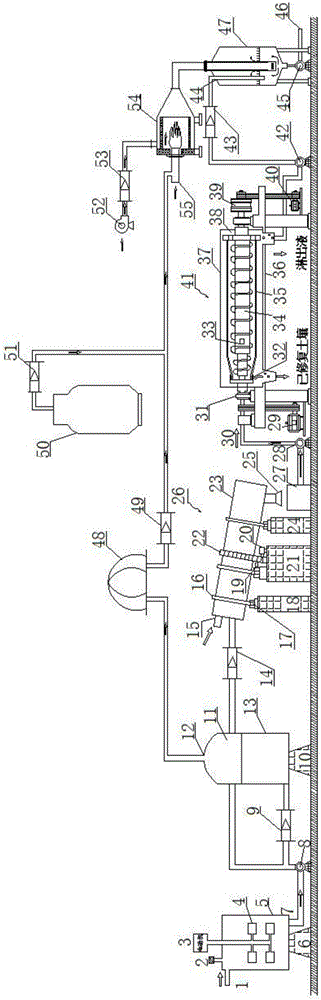

[0024] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0025] like figure 1 As shown, the heavy metal contaminated soil leaching repair system includes a rotary drum heavy metal leaching reactor 26, and also includes an agricultural and forestry waste hydrolysis acidification tank 5, and the agricultural and forestry waste hydrolysis acidification tank 5 is connected to the inlet of the first water pump 8, and the first water pump The outlet of 8 is connected to the liquid inlet of the rotary drum heavy metal rinsing reactor 26 through the second flowmeter 14, and the rotary drum heavy metal leaching reactor 26 includes a rinsing product outlet 25 and a polluted soil inlet 15, and the leaching product outlet 25 is below A mud-water mixing tank 27 is provided, and the mud-water mixing tank 27 is connected with the input end of the decanter centrifuge 41 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com