Environment-friendly anticorrosive paint and preparation method thereof

An anti-corrosion coating and environmental protection technology, applied in the field of coatings, can solve the problem that anti-corrosion coatings are not suitable for construction and repair, achieve excellent anti-corrosion performance and chemical resistance, increase toughness, and improve the effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Correspondingly, an embodiment of the present invention provides a method for preparing an environmentally friendly anti-corrosion coating, comprising the following steps:

[0041] S01. Take each component according to the formula of the above-mentioned environmental protection anticorrosion coating;

[0042] S02. Add low-viscosity solvent-free epoxy resin into the mixing tank, then add diluent, toughening resin, toner, seasoning, low-viscosity epoxy ester resin, and thixotropic agent in sequence, and stir separately to form paint main agent;

[0043] S03. Add the modified amine resin into the mixing tank, and stir to form a curing agent;

[0044] S04. The main agent and curing agent are mixed to form an environmentally friendly anti-corrosion coating.

[0045] Specifically, in the above-mentioned step S01, the formulation components and contents of the environmentally friendly anti-corrosion paint have been stated above, and will not be repeated here in order to save...

Embodiment 1

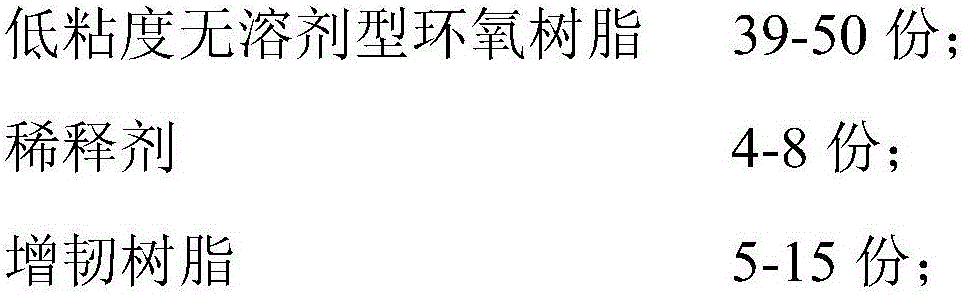

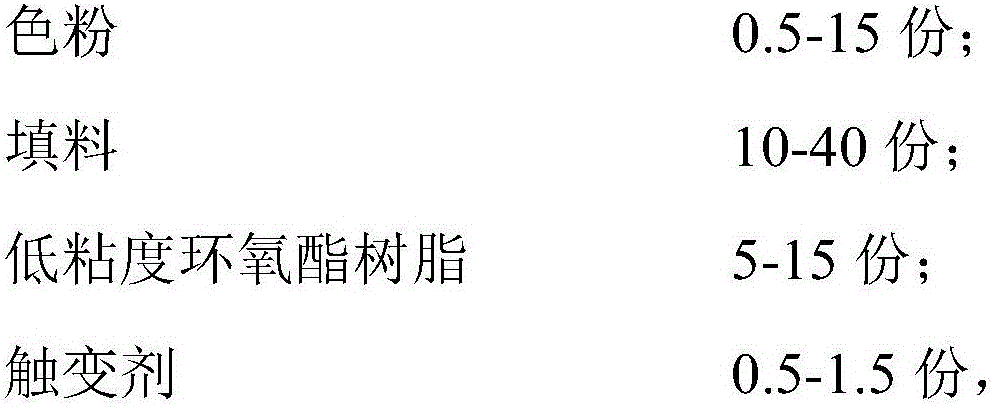

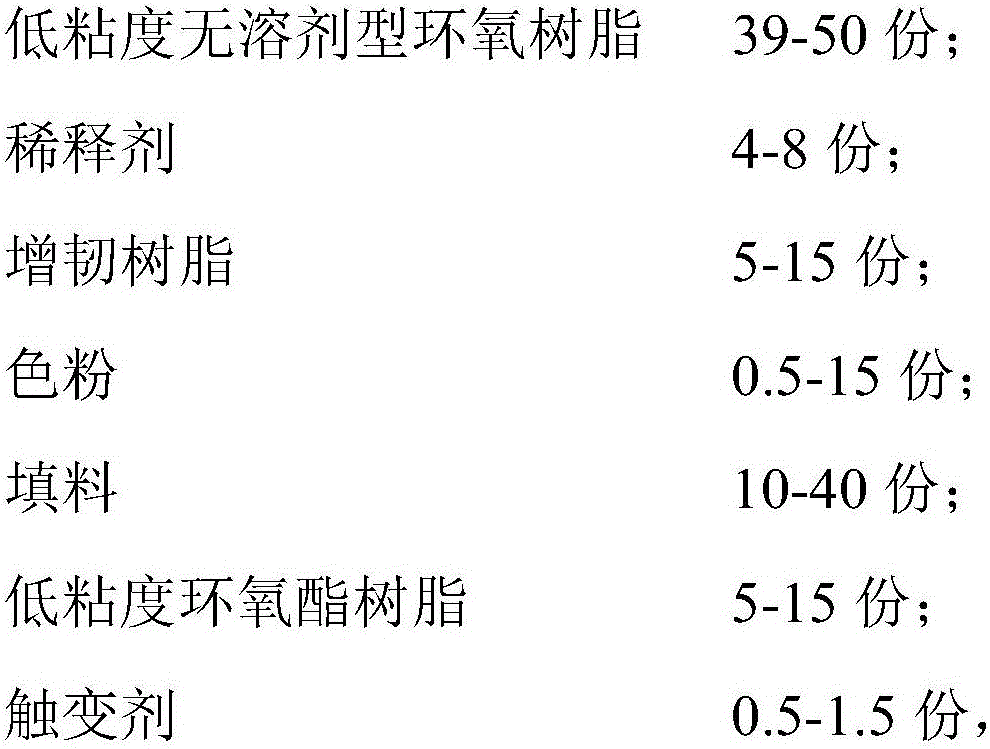

[0052] A kind of environment-friendly anticorrosion paint, comprises main agent and curing agent, with the parts by weight of said main agent being 100 parts by weight, including each component in parts by weight as shown in Example 1 of Table 1.

[0053] The preparation method of described environment-friendly anticorrosion coating, comprises the following steps:

[0054] S11. Take each component according to the formula of the above-mentioned environmental protection anticorrosion coating;

[0055] S12. Add the low-viscosity solvent-free epoxy resin into the mixing tank, then add the diluent into the mixing tank, and stir at a low speed (50RPM) to form a uniform first mixture; Add the resin to the first mixture, and stir at a low speed (50RPM) to form a uniform second mixture; add the toner to the second mixture, and stir at a low speed (50RPM) to form a uniform The third mixture: add the filler to the third mixture, and stir at a low speed (50RPM) to form a uniform fourth ...

Embodiment 2-11

[0059] The environmental protection anticorrosion paint, its component and its content respectively as including as shown in table 1 embodiment 2-11.

[0060] The preparation method of described environment-friendly anticorrosion coating is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com