Microcrystalline wax-modified cold patch asphalt mixture and preparation method thereof

A technology of cold patching asphalt and microcrystalline wax, which is applied in the field of asphalt pavement repair materials, can solve the problems of affecting the physical and mental health of construction workers, insufficient water peeling resistance and cohesiveness, and short service life, so as to overcome poor performance Excellent, not limited by climatic conditions, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

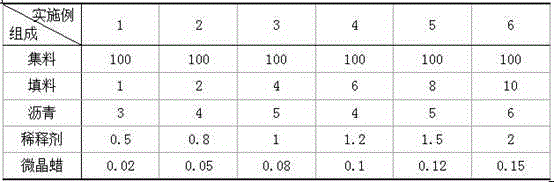

[0032] The preparation method of the cold-patch asphalt mixture of the microcrystalline wax modification of above-mentioned embodiment 1-6, it comprises the steps:

[0033] 1) According to the ingredients shown in Table 1 (aggregate is 1100g),

[0034] 2) Stir the aggregate and filler into an aggregate mixture;

[0035] 3) Heat the asphalt to 100-160°C, first add microcrystalline wax, stir to dissolve it completely in the asphalt, then add diluent and stir evenly to obtain asphalt mixture; wait until the temperature of the asphalt mixture drops to 20-50°C , and then stir the aggregate mixture and asphalt mixture evenly to obtain the microcrystalline wax-modified cold-patch asphalt mixture.

[0036] The performance of the cold-patch asphalt mixture modified by the microcrystalline wax prepared in Examples 1-6 is:

[0037] ①. Water peeling resistance: water immersion test (60 ℃ water bath for 24 hours) shows that the stone material shows that the coated asphalt film has almost...

Embodiment 7

[0045] It is basically the same as Example 4, except that the aggregate is limestone and the gradation is AC-16. The filler is lime. The asphalt is ABS modified asphalt. Described diluent is made up of solvent and additive, and its mass ratio is, solvent:additive=1:0.05; Wherein the solvent is diesel oil, and additive is soybean oil. Described microcrystalline wax is commercially available No. 70 industrial microcrystalline wax.

Embodiment 8

[0047] It is basically the same as Example 4, except that the aggregate is basalt rock, and the gradation is AC-16. The filler is fly ash. The asphalt is ABS modified asphalt. Described thinner is made up of solvent and additive, and its mass ratio is, solvent: additive=1: 0.5; Wherein solvent is kerosene, and additive is cottonseed oil.

[0048] The microcrystalline wax is a commercially available microcrystalline wax for industrial use, which is No. 75, No. 85 and No. 90 grades mixed in a mass ratio of 1:1:1.

[0049] The performance of the cold-patch asphalt mixture modified by microcrystalline wax prepared in Examples 7-8 is:

[0050] ①. Water peeling resistance: water immersion test (60 ℃ water bath for 24 hours) shows that the stone material shows that the coated asphalt film has almost no peeling off, and the asphalt coating rate is 99%.

[0051] ②. Low temperature working temperature and frost resistance: Keep it in the refrigerator at -10°C for 24 hours, take it ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com