Black aluminum composite board and preparation method thereof

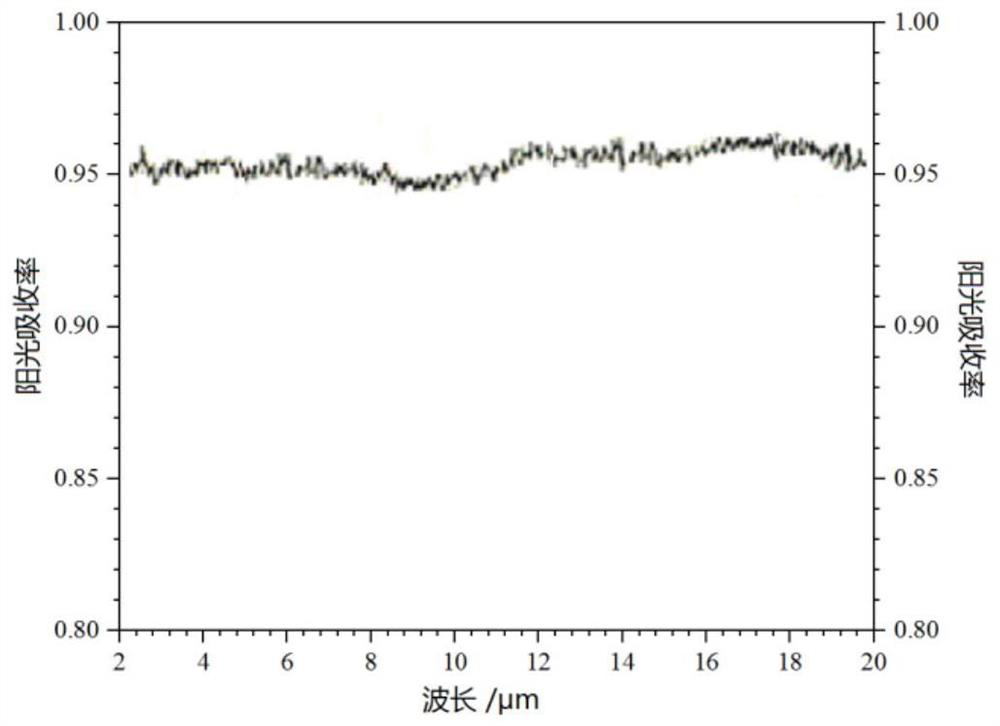

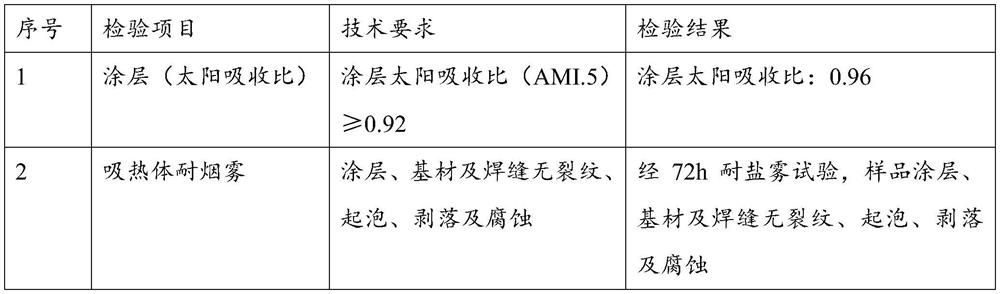

A technology of aluminum composite board and composite powder, which is applied in the field of solar energy, can solve the problems of attenuation of heat absorption efficiency and short life, and achieve the effects of simplifying the production process, no peeling and corrosion, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A black aluminum composite plate, the weight percentage of each raw material is composed of: aluminum alloy 55%, graphite 11%, carbon black 16%, silicon carbide 8%, Fe 3 O 4 5%, MnO 2 3%, Co 2 O 3 2%.

[0033] The preparation steps of the black aluminum composite panel are as follows:

[0034] (1) High-energy ball milling of black inorganic powder, black metal oxide powder and aluminum alloy powder to nano-scale particles respectively;

[0035] (2) the above-mentioned nano-scale particle powder is uniformly mixed and stirred according to the above-mentioned proportion to form nano-black aluminum composite powder;

[0036] (3) Press the nano-black aluminum composite powder into a black aluminum composite panel blank in a vacuum hot pressing sintering furnace, and the pressing pressure is 15T;

[0037] (4) The vacuum hot pressing sintering furnace is heated to 500°C, so that the black aluminum composite panel blank is in a semi-melting and semi-solidified state u...

Embodiment 2

[0043] A black aluminum composite plate, the weight percentage of each raw material is composed of: aluminum alloy 45%, graphite 13%, carbon black 19%, silicon carbide 10%, Fe 3 O 4 5%, MnO 2 3%, CuO 2%, Co 2 O 3 3%.

[0044] The preparation steps of the black aluminum composite panel are as follows:

[0045] (1) High-energy ball milling of black inorganic powder, black metal oxide powder and aluminum alloy powder to nano-scale particles respectively;

[0046] (2) the above-mentioned nano-scale particle powder is uniformly mixed and stirred according to the above-mentioned proportion to form nano-black aluminum composite powder;

[0047] (3) Press the nano-black aluminum composite powder into a black aluminum composite panel blank in a vacuum hot pressing sintering furnace, and the pressing pressure is 1.8T;

[0048] (4) The vacuum hot pressing sintering furnace is heated to 520°C, so that the black aluminum composite slab blank is in a semi-melting and semi-solidifie...

Embodiment 3

[0051] A black aluminum composite plate, the weight percentage of each raw material is composed of: aluminum alloy 45%, graphite 13%, carbon black 19%, silicon carbide 10%, Fe 3 O 4 2%, MnO 2 1%, CuO 2%, Co 2 O 3 3%.

[0052] The preparation steps of the black aluminum composite panel are as follows:

[0053] (1) High-energy ball milling of black inorganic powder, black metal oxide powder and aluminum alloy powder to nano-scale particles respectively;

[0054] (2) the above-mentioned nano-scale particle powder is uniformly mixed and stirred according to the above-mentioned proportion to form nano-black aluminum composite powder;

[0055] (3) Pressing the nano-black aluminum composite powder into a black aluminum composite panel blank in a vacuum hot pressing sintering furnace, and the pressing pressure is 2T;

[0056] (4) The vacuum hot pressing sintering furnace is heated to 520°C, so that the black aluminum composite panel blank is in a semi-molten and semi-solidified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com