Ceramic solar panel pressed by ceramic powder and provided with access pipe orifice

A technology of ceramic powder and solar heat collector, which is applied in the field of solar heat collectors, can solve the problems of easy attenuation of sunlight absorption rate, reduction of heat exchange area, and reduction of heat collection efficiency, so as to improve the efficiency of light-to-heat conversion and reduce the amount of raw materials , the effect of high heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

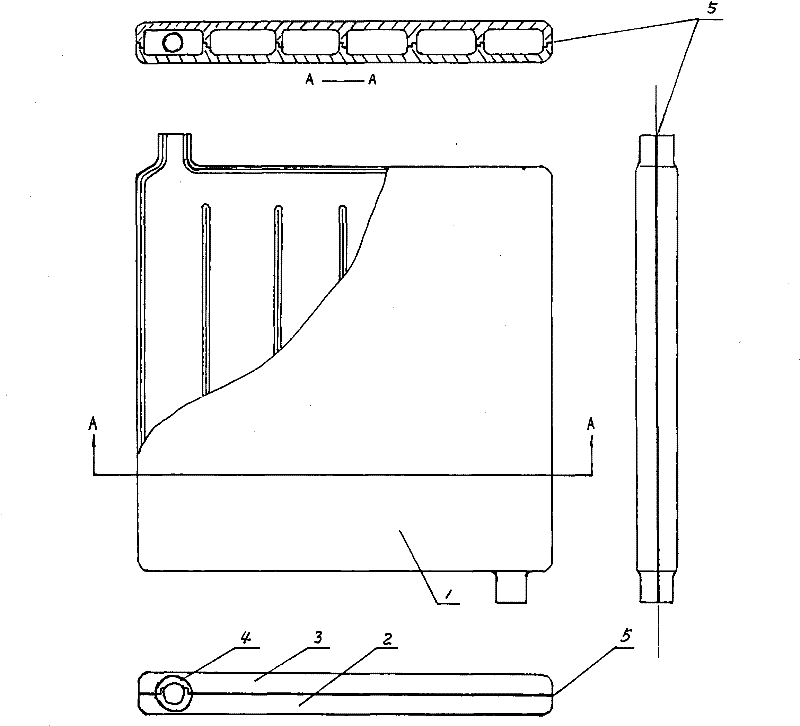

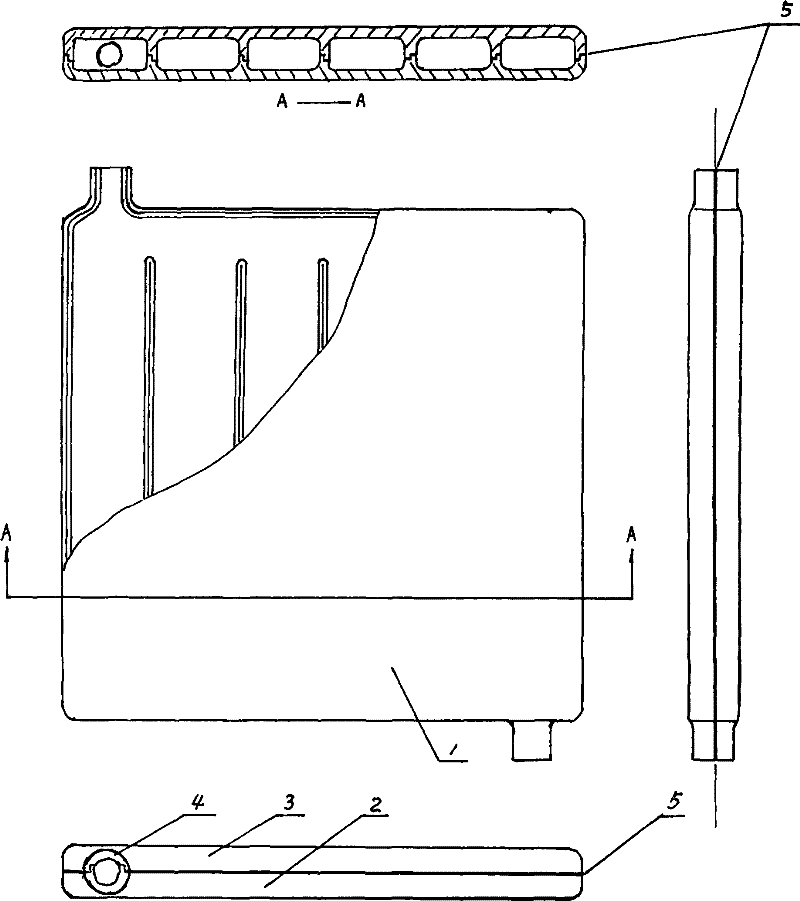

[0041] 1. The upper half box and lower half box biscuits with half pipe mouth and supporting ribs are pressed and formed with ceramic powder, and are bonded with low melting point ceramic mud to form a hollow ceramic plate with a flat box structure with inlet and outlet nozzles. Blank, the edge of the semi-box-shaped green blank has steps, and the vanadium-titanium black porcelain slurry is sprayed on the sunny surface, dried and sintered at 1210°C to become a flat box-type black porcelain composite ceramic solar panel with inlet and outlet nozzles.

[0042] 2. The upper half box and lower half box biscuits with half pipe mouth and support ribs pressed and formed with ceramic powder, with a wall thickness of 3 mm, are bonded with ordinary ceramic mud to form a flat box structure with inlet and outlet pipe mouths. Hollow ceramic plate green body, semi-box-shaped green body with steps on the edge, spray vanadium-titanium black porcelain slurry on its sunny surface, dry and sinter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com