Three-dimensional printing device capable of realizing electric field induction assisted electrospray

An electric field induction and three-dimensional printing technology, which is applied in processing and manufacturing, liquid material additive processing, additive processing, etc., can solve problems such as difficult to manufacture three-dimensional structures, limited nozzle hole processing, and difficult to realize submicron and below structure processing. , to achieve the effect of fast forming speed and high printing resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

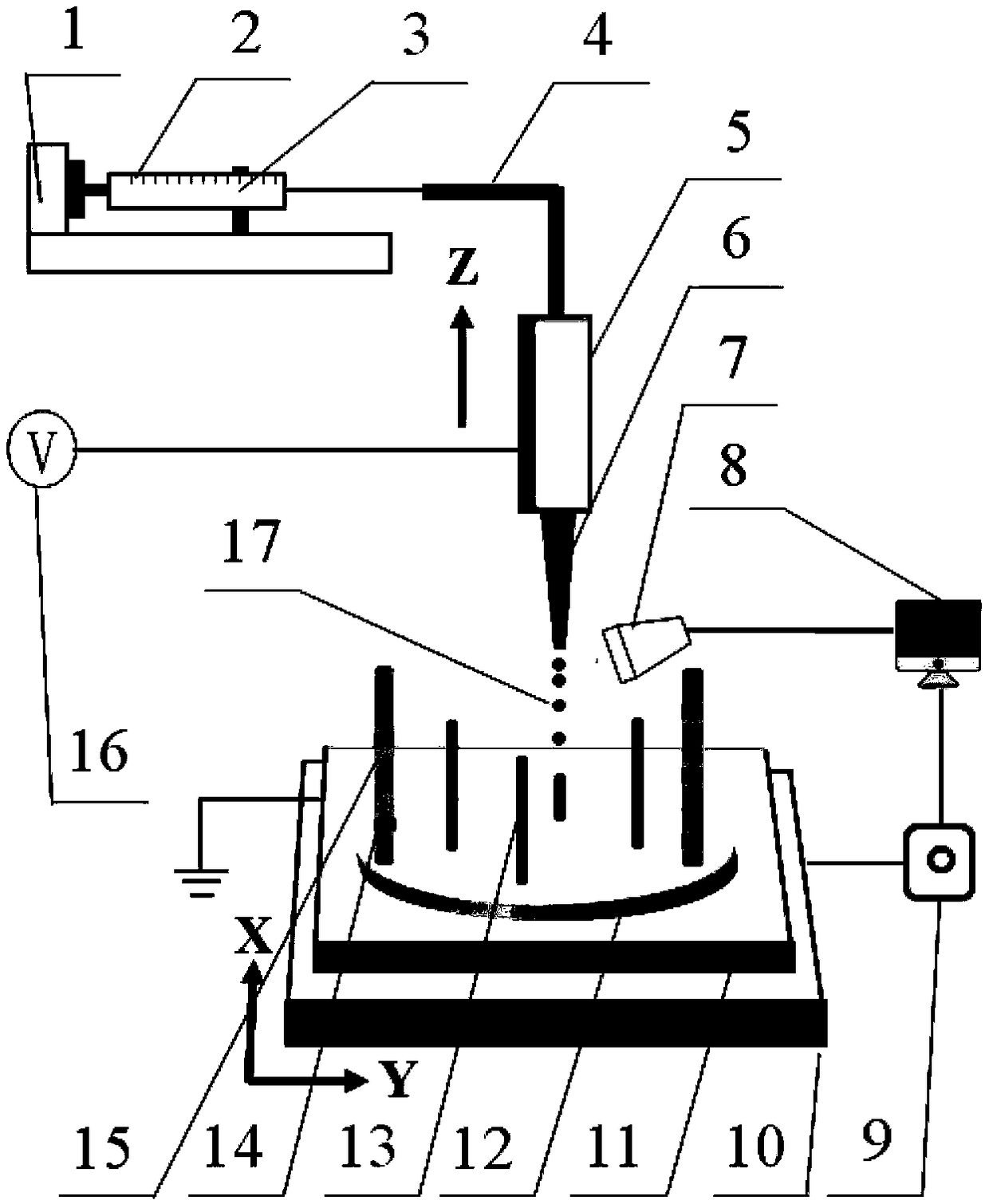

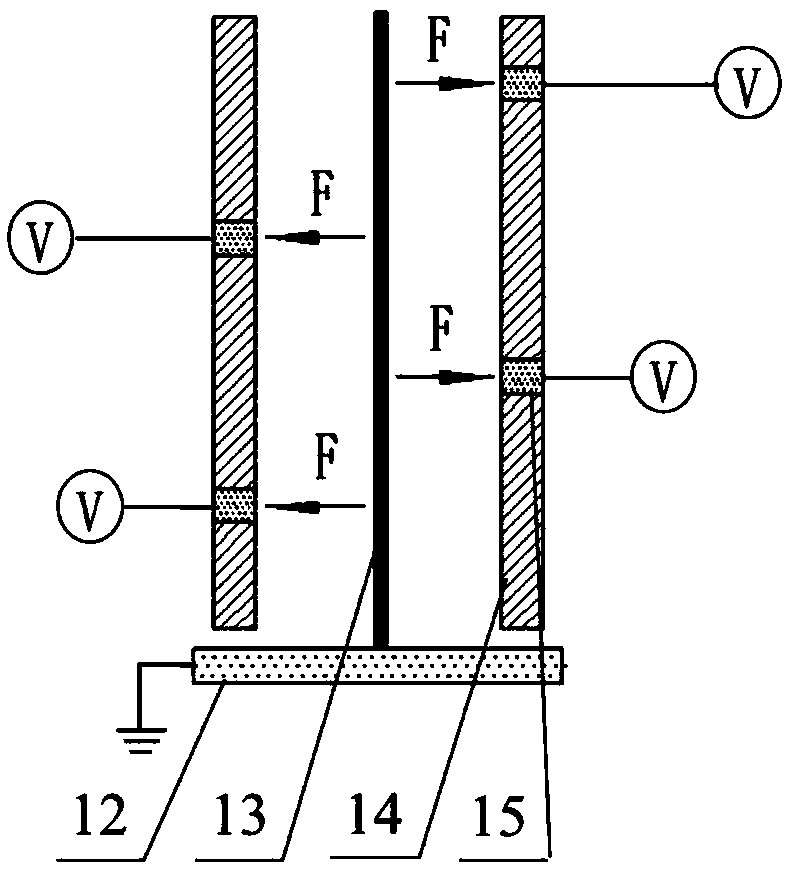

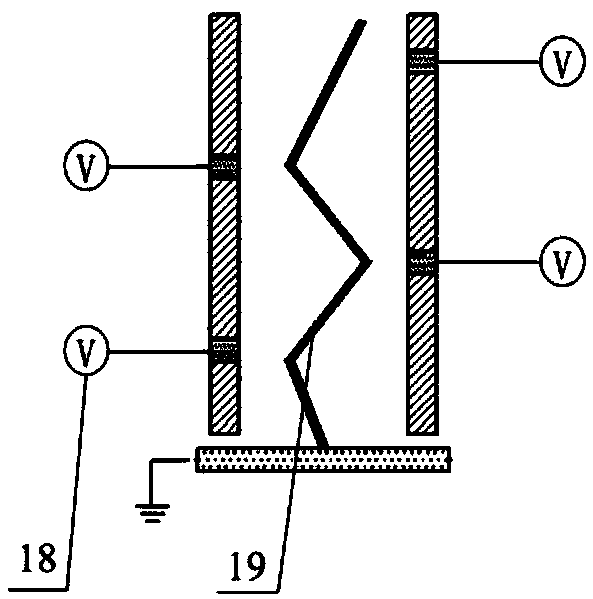

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. An embodiment of a three-dimensional printing device using electric field induction assisted electrospray mainly includes an electrospray printing module and an electric field induction forming module.

[0024] The precision syringe 2 has a volume range of 25-1000 μL and is placed on the precision syringe pump 1. The precision syringe 2 inhales the silver sol functional material solution 3, and passes through the catheter 4. 5μLmin -1 The flow rate of the functional material solution 3 is transported to the nozzle of the injection needle 6; the injection needle clamp 5 is fixed on the Z axis for holding the injection needle 6, and the injection needle 6 is made of stainless steel or quartz material, and the inner diameter is 5- 500 μm; the camera 7 presents the jet behavior in the printing process in the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com