Substrate specially for digital card-making and its preparing method

A substrate and digital technology, which is applied to the special substrate for digital card making and the preparation of the substrate, and the field of digital printing cards, can solve problems such as inapplicability, and achieve high durability, high definition and accurate color reproduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

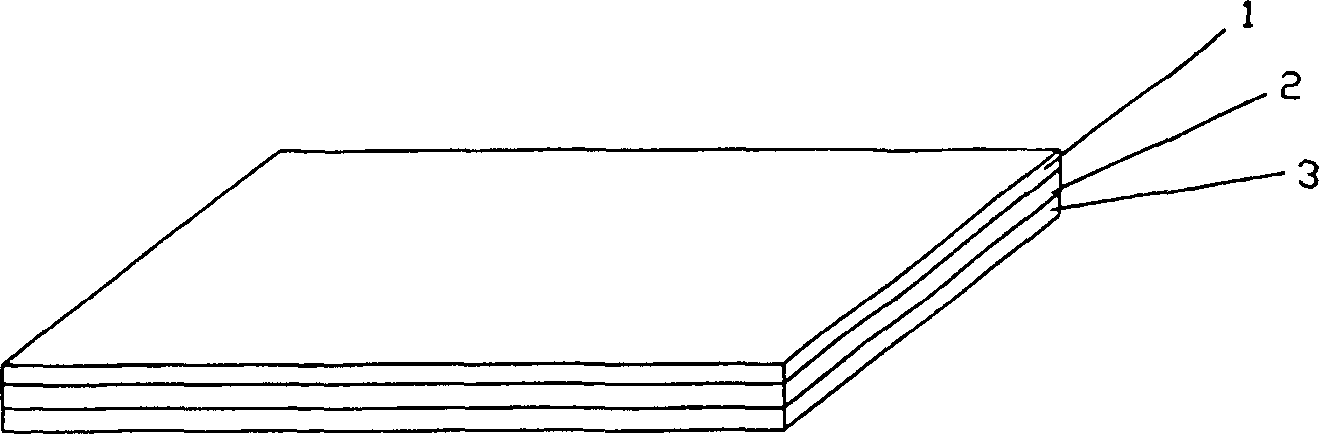

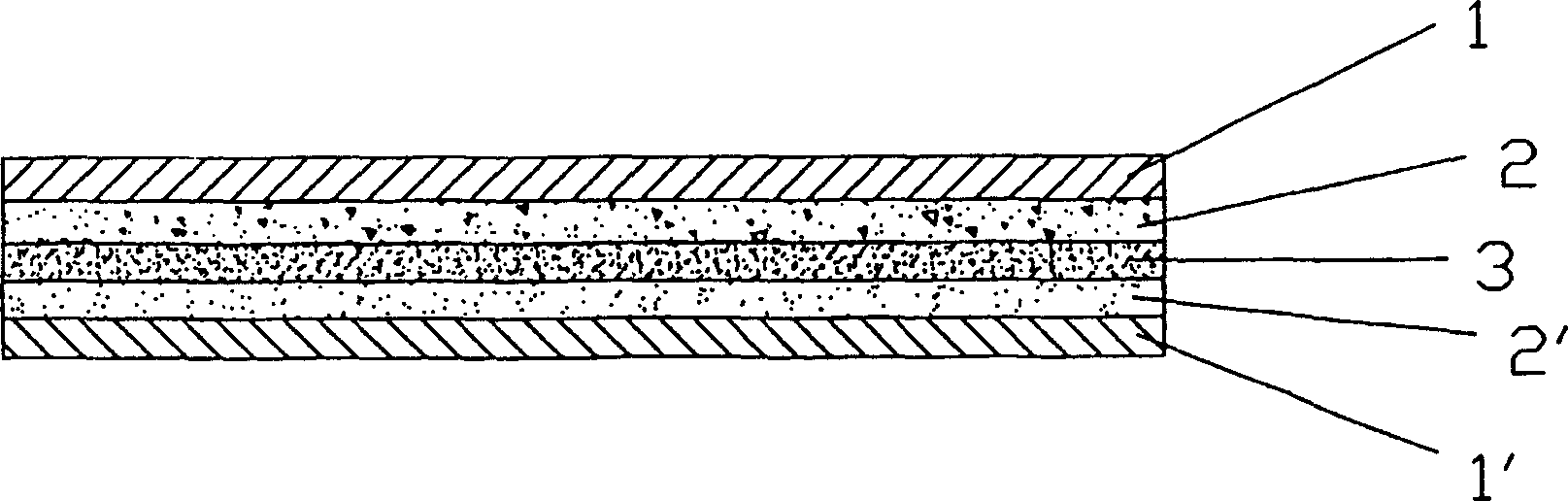

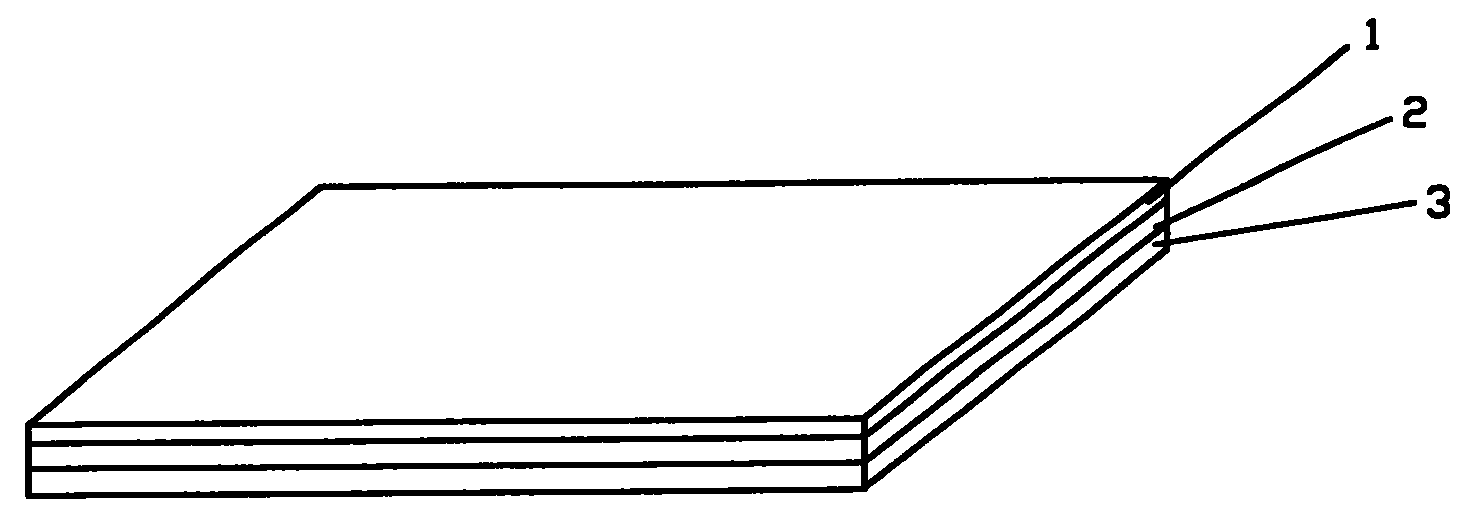

[0009] The difference between the digital card substrate provided by the present invention and the currently commonly used digital card substrate is that its structure includes a polymer substrate and an adhesive layer and an ink-absorbing layer that are sequentially coated on the surface of the substrate, that is, the substrate It includes a polymer base material, an adhesive layer is coated on the surface of the base material, and an ink absorbing layer is coated on the surface of the adhesive layer. Wherein: the macromolecule substrate comprises polyvinyl chloride (PVC), methacrylate-butadiene-styrene copolymer (MBS), polyethylene terephthalate (PET) and polycarbonate ester (PC) translucent substrate, or selected from degradable PVC, polyvinyl chloride and acrylonitrile-butadiene-styrene copolymer blend material (PVC / ABS), polyvinyl chloride and calcium carbonate hybrid material ( PVC / CaCO 3 ), PET and ABS opaque substrates. These base materials of different materials can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com