Novel high-resolution printing method based on satellite droplet

A satellite droplet and high-resolution technology, which is applied in printing and other fields, can solve problems affecting printing quality and ink flying, and achieve high-efficiency and high-resolution printing, improved printing resolution, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

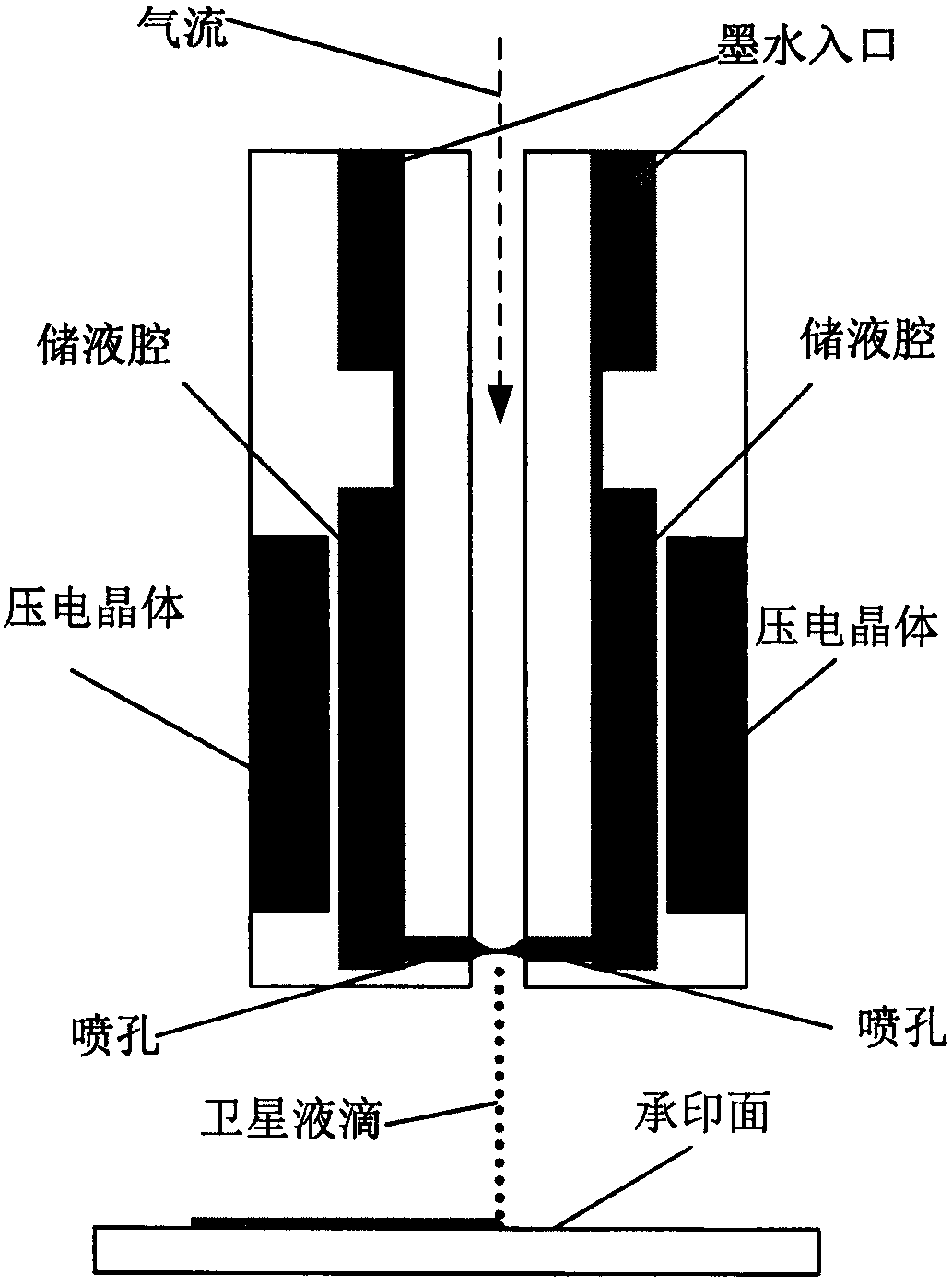

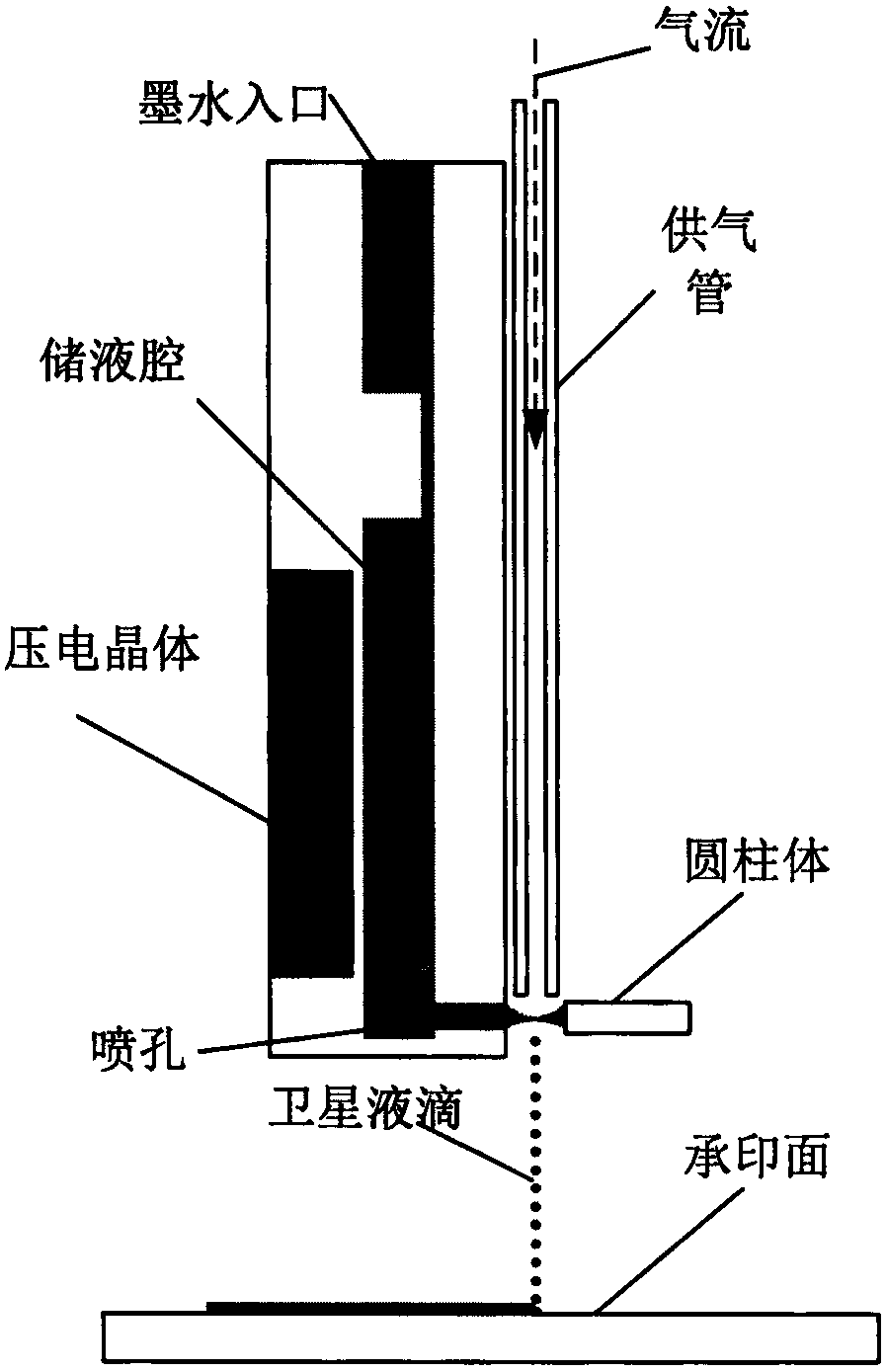

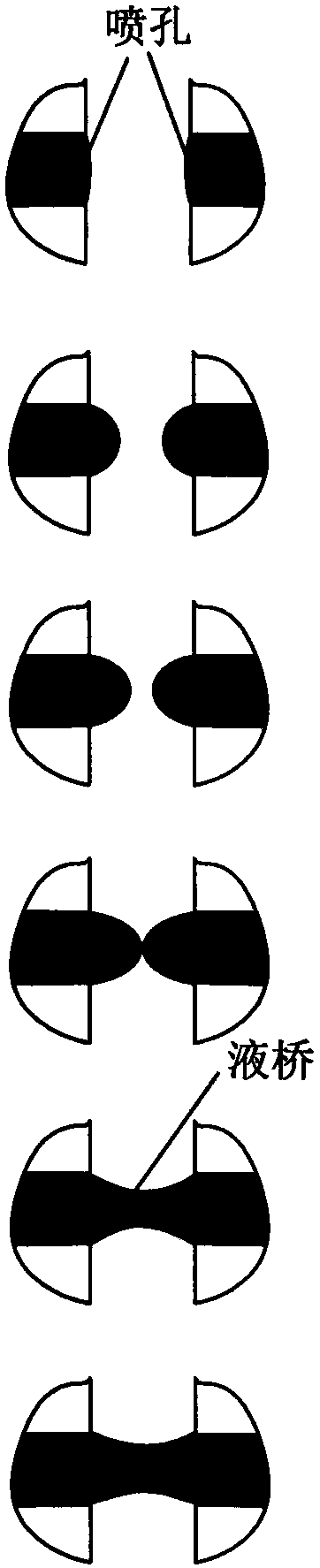

[0016] The present invention is achieved through the following technical solutions. In the present invention, two nozzle holes of the same size are placed opposite each other, and the ink in the liquid storage chamber is squeezed out from the nozzle hole through the piezoelectric crystal; the volume of the liquid storage chamber is changed through the deformation of the piezoelectric crystal, so that the ink is squeezed out from the nozzle hole out; by controlling the deformation amount and deformation speed of the piezoelectric ceramics, the extrusion amount of the ink is enough to form a liquid bridge, but it is not separated from the nozzle hole; after the liquid bridge is formed, the piezoelectric crystal reversely deforms, and the liquid The ink in the bridge is sucked into the liquid storage chamber through the nozzle hole, causing the liquid bridge to break and form satellite droplets; then the satellite droplets are blown off the printing surface by an airflow of approp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com