Array substrate, manufacturing method of array substrate, display panel and manufacturing method of display panel

A technology of an array substrate and a manufacturing method, which is applied in the display field and can solve problems such as low printing resolution and high difficulty of printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

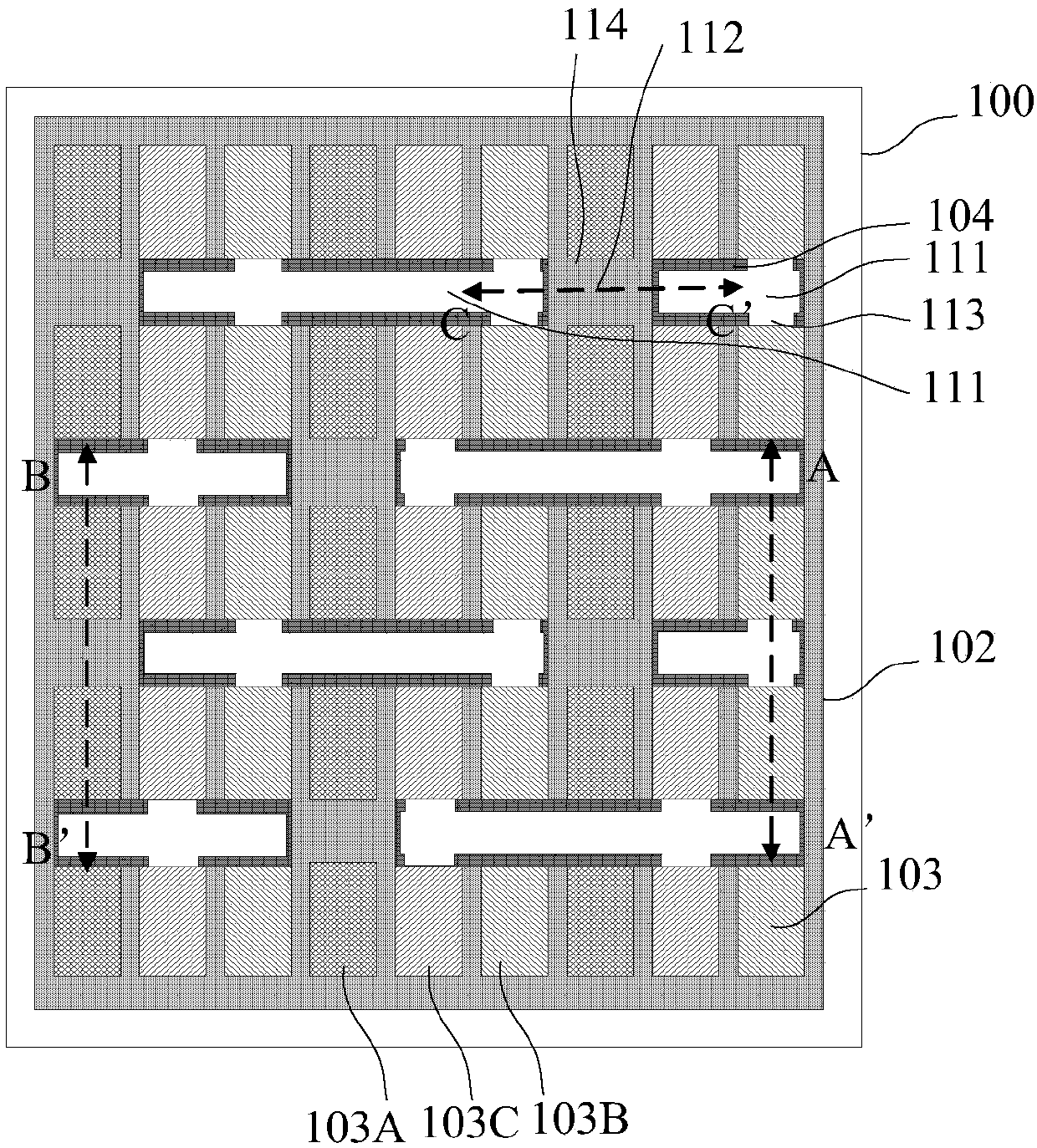

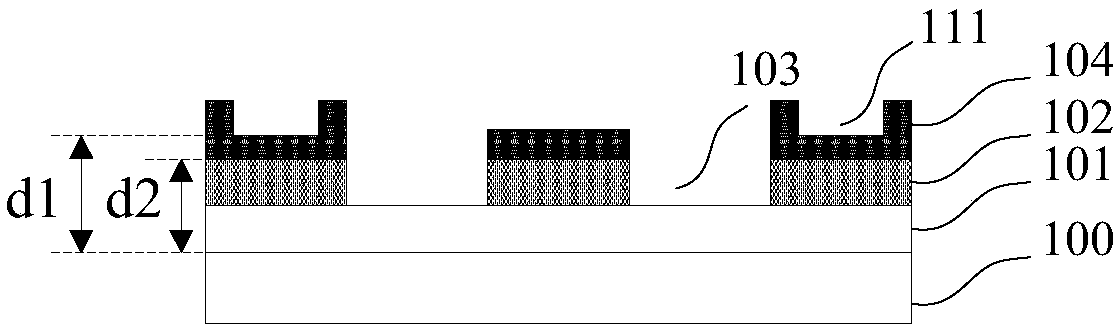

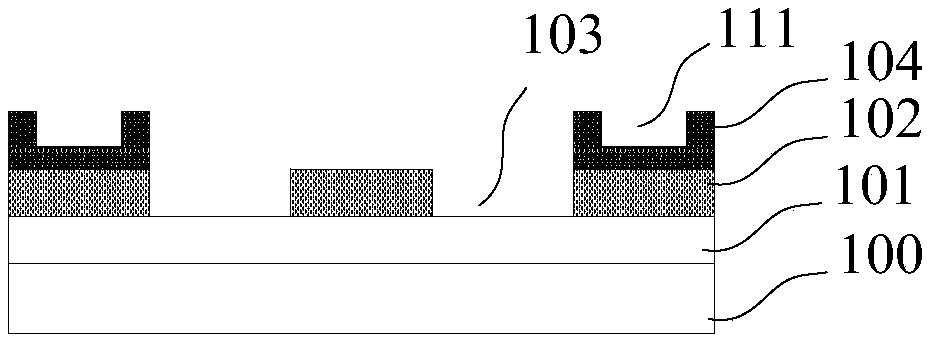

[0046] figure 1 is a schematic structural diagram of an array substrate according to an embodiment of the present invention, figure 2 for figure 1 The partial sectional view of the array substrate shown along section A-A', image 3 for figure 1 The partial cross-sectional view of the array substrate shown along section B-B'.

[0047] combine figure 1 , figure 2 with image 3 As shown, the embodiment of the present invention provides an array substrate, including: a base substrate 100, an electrode layer 101 formed on the base substrate 100, and a first pixel defining layer 102. The first pixel defining layer 102 connects the base substrate 100 is divided into a plurality of sub-pixel regions 103; a second pixel-defining layer 104 is formed on the first pixel-defining layer 102 between at least two adjacent rows of sub-pixel regions 103, and the second pixel-defining layer 104 is provided with multiple a first groove 111, a second groove 112 is arranged between two adjac...

Embodiment 2

[0083] The embodiment of the present invention also provides a display panel, the display panel includes Figure 1 to Figure 6 Either one of the array substrates shown.

[0084] For the specific description of the array substrate, reference may be made to the description of Embodiment 1, which will not be repeated in this embodiment of the present invention.

[0085] In the embodiment of the present invention, the display panel further includes a light-emitting layer formed in the sub-pixel region 103. By inkjet printing, the first light-emitting layer is formed in the sub-pixel region 103A of the first color, and the sub-pixel of the second color A second light-emitting layer is formed in the region 103B, and a third light-emitting layer is formed in the sub-pixel region 103C of the third color.

[0086] In an embodiment of the present invention, the display panel includes an array substrate, adopts a double-layer pixel defining layer structure, and forms a second pixel defi...

Embodiment 3

[0088] refer to Figure 7 , which shows a flow chart of a method for manufacturing an array substrate according to an embodiment of the present invention, which may specifically include the following steps:

[0089] Step 701, forming an electrode layer on a base substrate.

[0090] In the embodiment of the present invention, the electrode layer 101 is formed on the base substrate 100 .

[0091] Wherein, the electrode layer 101 is generally an anode layer, and its material is ITO (Indium Tin Oxide, indium tin oxide); the base substrate 100 can be a glass substrate, a quartz substrate, a metal substrate, a resin substrate, and the like.

[0092] Step 702, forming a first pixel defining layer on the electrode layer.

[0093] In the embodiment of the present invention, the first pixel defining layer 102 is formed on the electrode layer 101 through a patterning process.

[0094] Specifically, a first pixel defining layer film is first deposited on the electrode layer 101 , and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com