Piezoelectric ink-jet printing device with outer surface electrode layer

一种喷墨打印、器件的技术

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

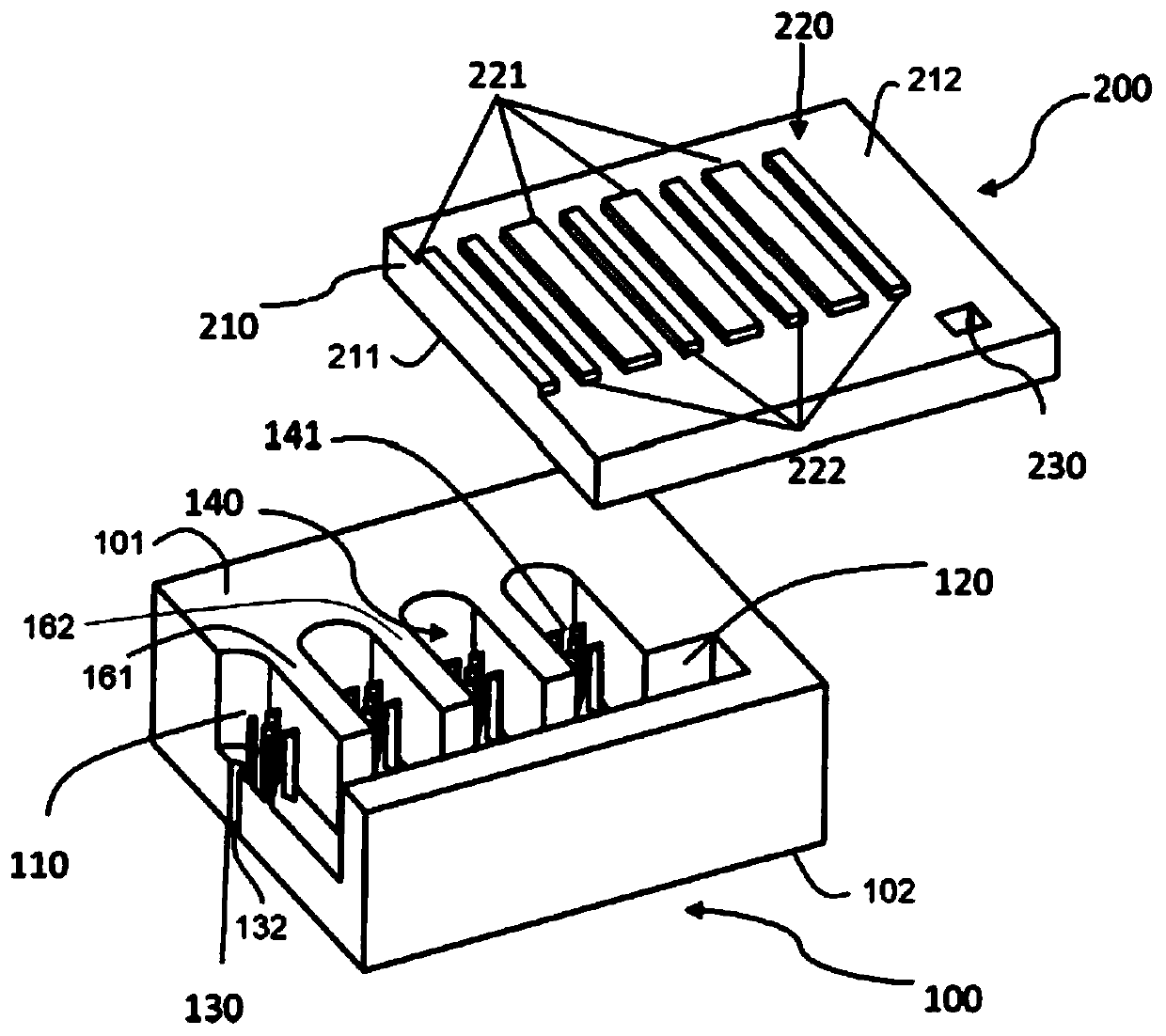

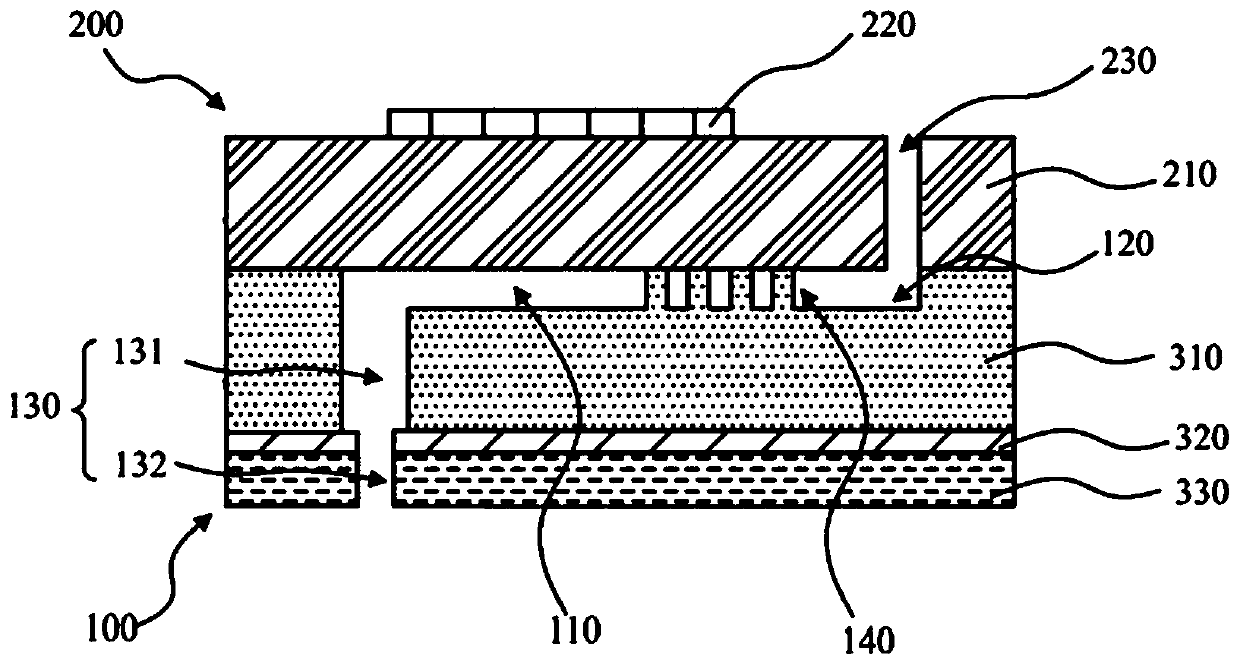

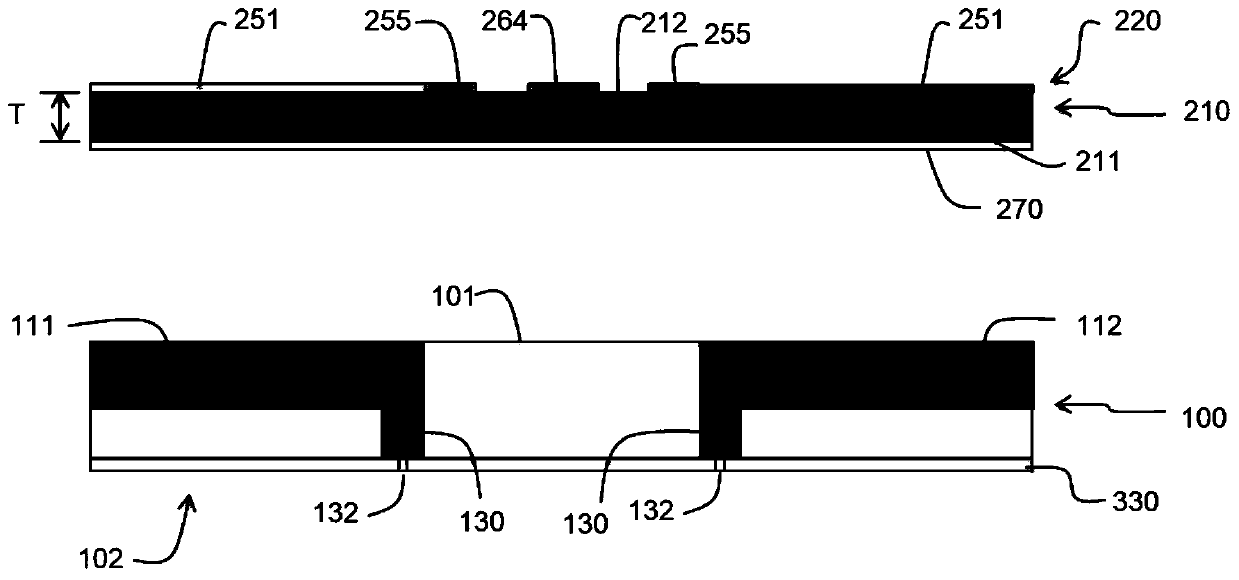

[0025] The present invention includes various combinations of the embodiments described herein. References to "specific embodiments" and the like refer to features present in at least one embodiment of the invention. Separate references to "one embodiment" or "a particular embodiment" and the like do not necessarily refer to the same embodiment or embodiments; however, unless explicitly indicated or obvious to those skilled in the art, these embodiments are not Mutually exclusive. When referring to "one method" or "multiple methods" and similar terms, the use of the singular or plural number is non-limiting. It is specifically noted that the use of "or" has no exclusive meaning in this article unless it is clearly indicated otherwise or required by the context. Words such as "above", "below", "above" or "below" are intended to describe the gap between features located in different planes Positional relationship, but it should be understood that in a device orientation, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com