A treatment method for solidification and stabilization of electrolytic manganese slag

A technology of stabilization treatment and stabilization treatment agent, which is applied in the field of electrolytic manganese slag solidification and stabilization treatment, can solve the problems of high price and poor fixation effect of ammonia nitrogen, and achieve the goal of reducing dosage, reducing the cost of solidification treatment, and strong physical and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh electrolytic manganese slag, add solidification and stabilization treatment agent (82.8% ferronickel slag, 17.2% sodium phosphate) by weight of electrolytic manganese slag, mix and stir for 5 minutes; then add water with 30% weight of electrolytic manganese slag, mix and stir for 5 minutes , The solidified and stabilized electrolytic manganese slag is sent to the slag warehouse for storage, in which the ferronickel slag is ground through an 80-mesh sieve, and the sieve residue is 4%.

[0017] The solidified and stabilized electrolytic manganese slag is leached by the "HJ 557-2010" method, and the toxicity leaching result is lower than the standard limit of "GB 8978-1996".

Embodiment 2

[0019] Weigh the electrolytic manganese slag, add solidification and stabilization treatment agent (76.5% ferronickel slag, 23.5% sodium phosphate) with 17% weight of electrolytic manganese slag, mix and stir for 6 minutes; then add water with 25% weight of electrolytic manganese slag, mix and stir for 3 minutes , The solidified and stabilized electrolytic manganese slag is sent to the slag warehouse for storage, in which the ferronickel slag is ground through an 80-mesh sieve with a sieve allowance of 3%.

[0020] The solidified and stabilized electrolytic manganese slag is leached by the "HJ 557-2010" method, and the toxicity leaching result is lower than the standard limit of "GB 8978-1996".

Embodiment 3

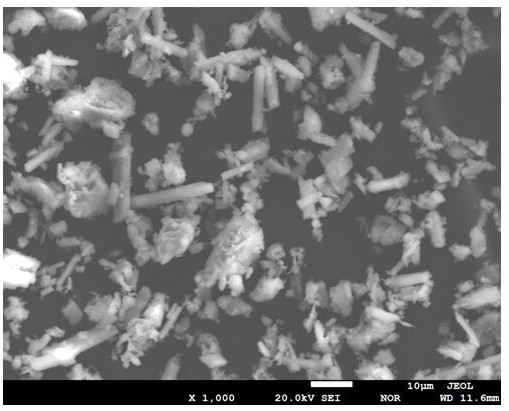

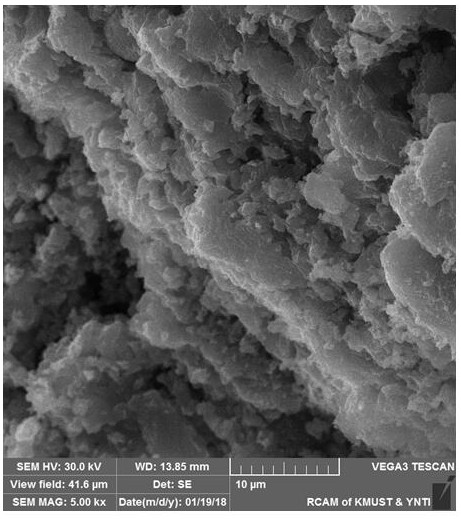

[0022] Weigh the electrolytic manganese slag, add solidification and stabilization treatment agent (68.4% ferronickel slag, 31.6% sodium phosphate) by weight of electrolytic manganese slag, mix and stir for 8 minutes; then add water with 33% weight of electrolytic manganese slag, mix and stir for 5 minutes , The solidified and stabilized electrolytic manganese slag is sent to the slag warehouse for storage, in which the ferronickel slag is ground through an 80-mesh sieve, and the sieve residue is 4%. The SEM photo of the solidified and stabilized electrolytic manganese slag is shown in figure 2 , it can be seen from the figure that after the electrolytic manganese slag is solidified and stabilized, its irregular particles and columnar particles ( figure 1 ) is integrated with the product gel to form a hardened body with a dense structure ( figure 2 ).

[0023] The solidified and stabilized electrolytic manganese slag is leached by the "HJ 557-2010" method, and the toxicity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com