Composite curing agent forchemical nickel plating waste liquid evaporation concentrated solution as well as preparation method and application of composite curing agent

A technology of composite curing agent and evaporative concentrated solution, which is applied in chemical instruments and methods, metallurgical wastewater treatment, neutralization water/sewage treatment, etc., can solve the problem of increasing solid waste outsourcing costs, increasing the cost of curing agent, and the amount of curing agent used Large and other problems, to achieve the effect of reducing the amount of outsourcing, increasing the specific surface area and adsorption capacity, and fast curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Present embodiment is the preparation of composite curing agent, and its steps are:

[0049] S1 Acid modification of bentonite:

[0050] Immerse bentonite in 0.5mol / L HCl solution for 12 hours to ensure that the Ca contained in bentonite 2 + , Mg 2+ 、Al 3+ Plasma dissolution can also achieve the purpose of dredging the pore size;

[0051] S2 Wash the slurry with deionized water to neutrality and then dry it in an oven at 95°C;

[0052] S3 Place the dried bentonite in a muffle furnace that has been evacuated and filled with nitrogen to protect it, and raise the temperature to 300°C at a rate of 5°C / min and keep it for 3h. After the calcination is completed and cooled, pass it through a 200-mesh nylon screen.

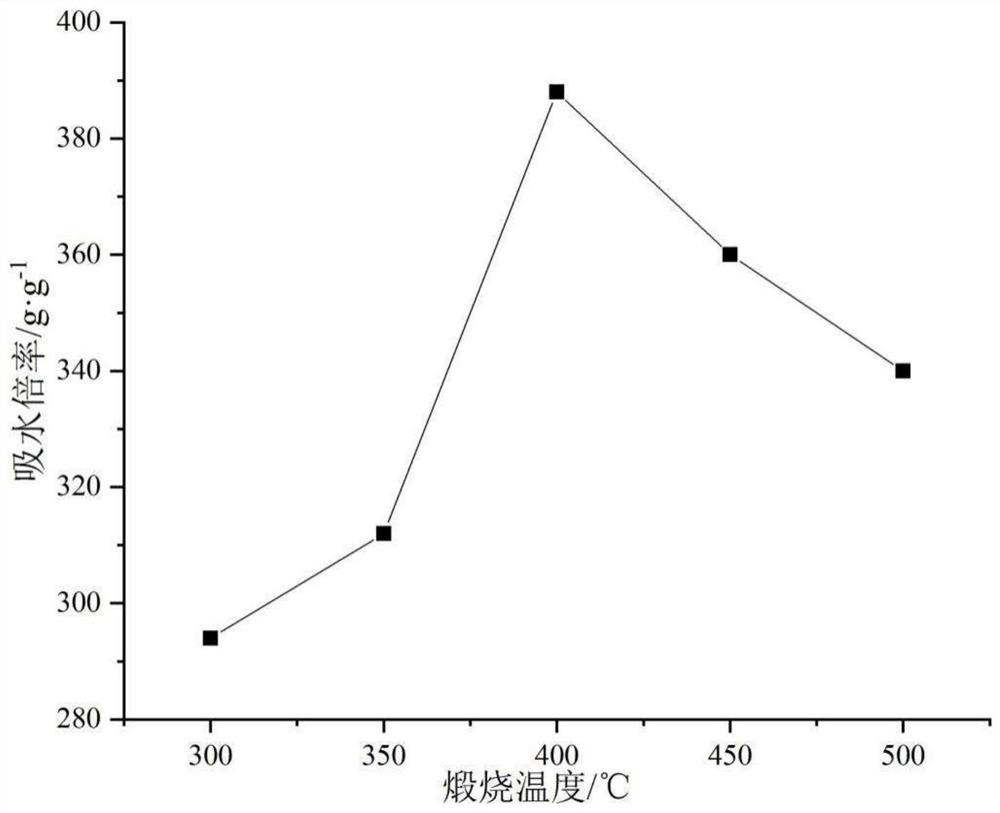

[0053] see figure 1 , the water absorption rate of the modified bentonite in this process was tested to be 294g·g -1 .

[0054] In S4, 6 kg of modified bentonite, 1 kg of polyferric chloride, 1 kg of soda lime passed through a 100-mesh screen, and 2 kg of c...

Embodiment 2

[0056] Present embodiment is the preparation of composite curing agent, and its steps are:

[0057] S1 Acid modification of bentonite:

[0058] Immerse bentonite in 0.5mol / L HCl solution for 12 hours to ensure that the Ca contained in bentonite 2 + , Mg 2+ 、Al 3+ Plasma dissolution can also achieve the purpose of dredging the pore size;

[0059] S2 Wash the slurry with deionized water to neutrality and then dry it in an oven at 95°C;

[0060] S3 Place the dried bentonite in a muffle furnace that has been evacuated and filled with nitrogen, and raise the temperature to 350°C at a rate of 5°C / min and keep it for 3h. After the calcination is completed and cooled, pass it through a 200-mesh nylon screen.

[0061] see figure 1 , the water absorption rate of the modified bentonite in this process was tested to be 312g·g -1 .

[0062] In S4, 3.5 kg of modified bentonite, 3.5 kg of polyferric chloride, 1.5 kg of soda lime and 1.5 kg of cement passed through a 100-mesh screen a...

Embodiment 3

[0064] Present embodiment is the preparation of composite curing agent, and its steps are:

[0065] S1 Acid modification of bentonite:

[0066] Immerse bentonite in 0.5mol / L HCl solution for 12 hours to ensure that the Ca contained in bentonite 2 + , Mg 2+ 、Al 3+ Plasma dissolution can also achieve the purpose of dredging the pore size;

[0067] S2 Wash the slurry with deionized water to neutrality and then dry it in an oven at 95°C;

[0068] S3 Place the dried bentonite in a muffle furnace that has been evacuated and filled with nitrogen, and raise the temperature to 400°C at a rate of 5°C / min and keep it for 3h. After the calcination is completed and cooled, pass it through a 200-mesh nylon screen.

[0069] see figure 1 , the water absorption rate of the modified bentonite in this process was tested to be 388g·g -1 . The water absorption rate at this temperature is the highest.

[0070] In S4, 4.5kg of modified bentonite, 1.5kg of polyferric chloride, 1kg of soda li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com