Composite material for weaving

A composite material and fabric layer technology, applied in the field of textile composite materials, can solve the problems of obvious crystallization tendency, processing performance, poor elastic strength and adhesion, poor weather resistance, etc., and achieve high breaking strength and tearing strength, strong physical and mechanical properties. , the effect of high protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Polyvinylidene chloride (PVDC) is a kind of plastic, in addition to the general properties of plastics, it also has high barrier properties. At present, PVDC has a large number of applications in food packaging. For example, the casings of ham sausage products are currently made of PVDC film. So far, although there are some patent applications, most of them are used in packaging products to achieve the function of moisture-proof and fresh-keeping. For example, the utility model with application number 90210463.2 mainly uses PDVC for paper packaging; the invention with application number 00119751.7 mainly It uses PDVC in liquid packaging; patent No. 03234637.9 mainly uses PDVC as the packaging of medicines.

[0017] However, there is currently no application of textile composites for safety protection, especially for protection against toxic gases. The present invention is described in detail below.

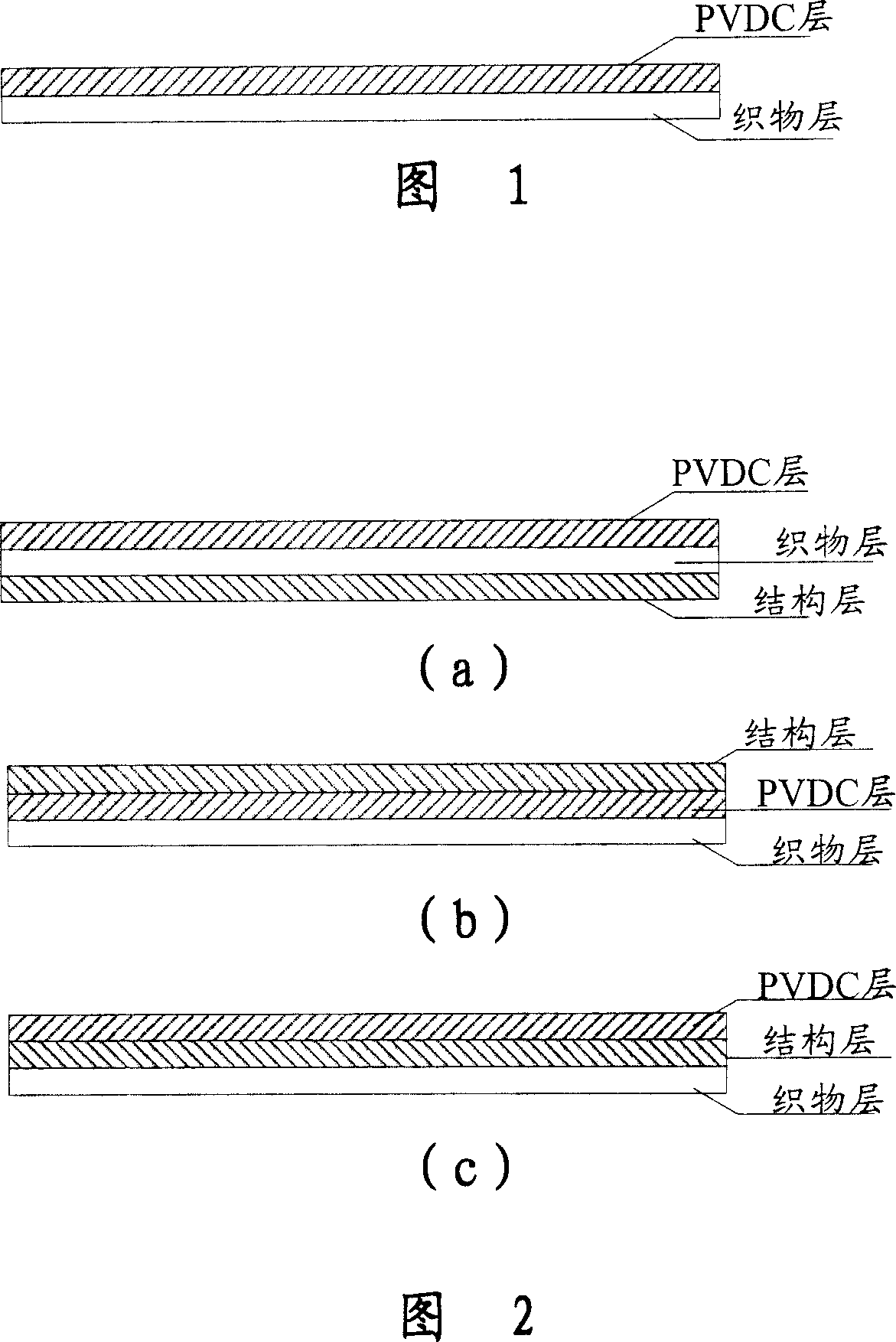

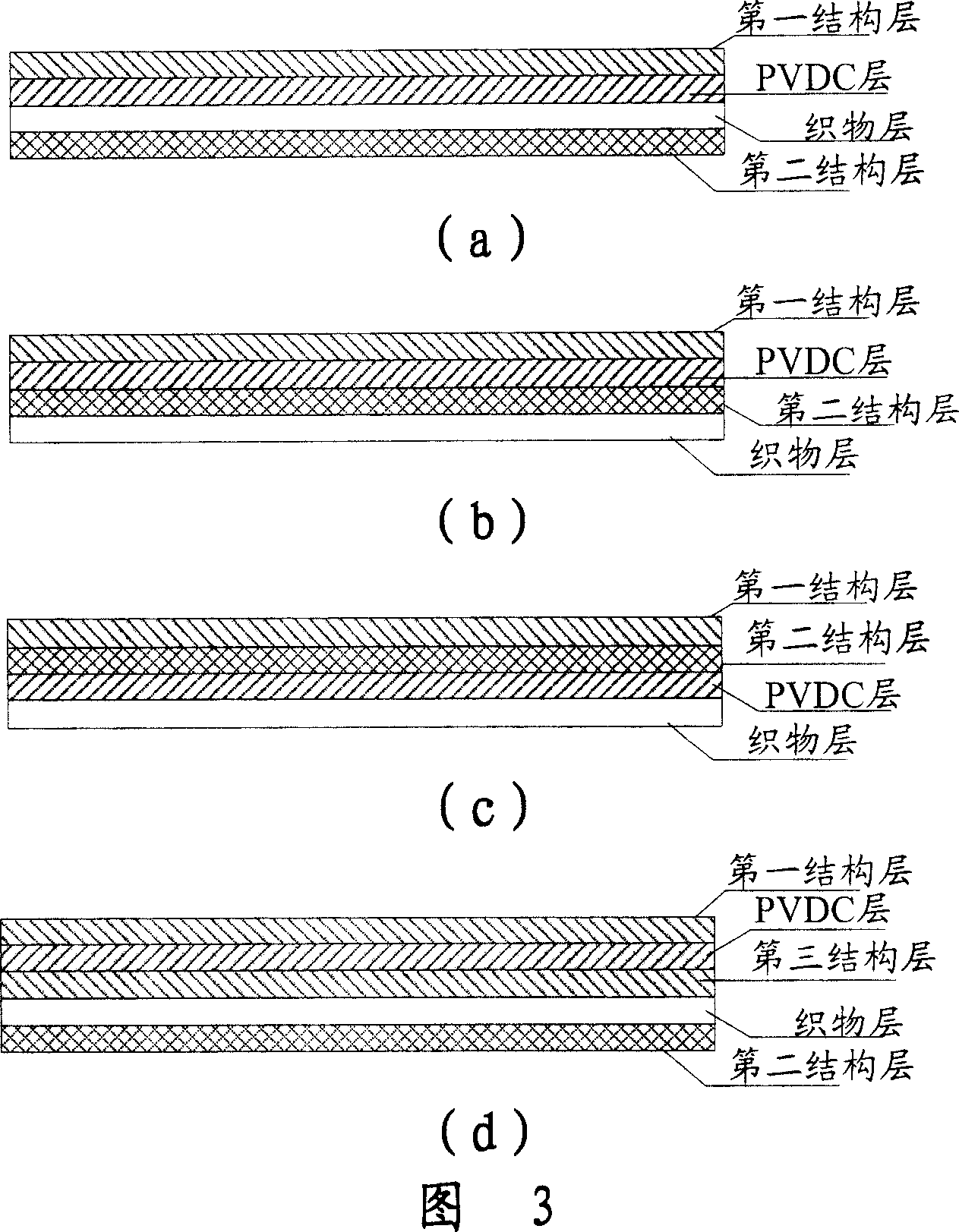

[0018] The textile composite material of the present invention inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com