Food-packaging film with preservation effect

A technology of food packaging film and anti-corrosion effect, applied in the field of food packaging film, can solve the problems of white pollution, impact on the environment, accumulation, etc., achieve the effect of strong physical and mechanical properties, protect the ecological environment, and avoid white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

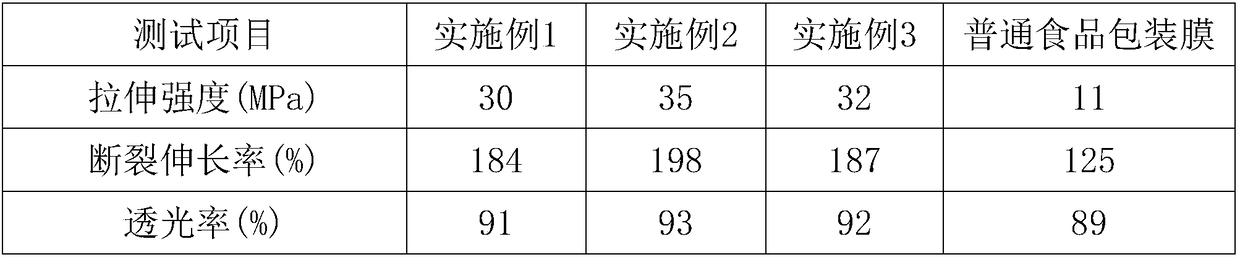

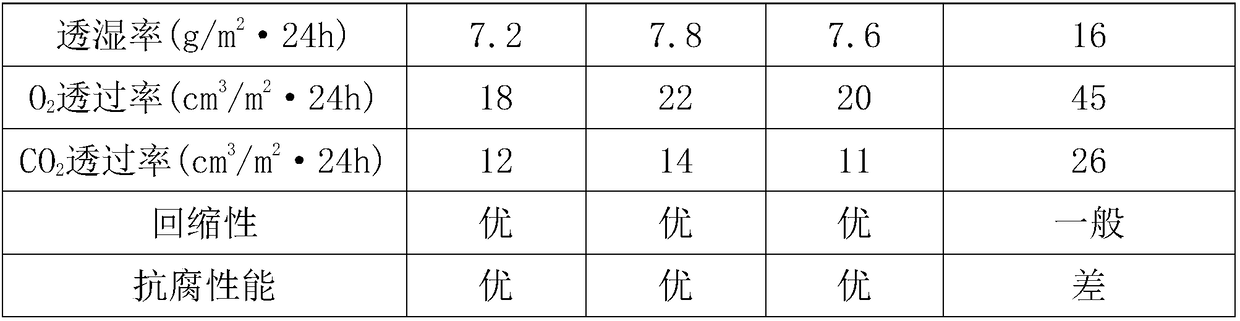

Examples

Embodiment 1

[0020] A food packaging film with antiseptic effect is characterized in that it is made of the following raw materials in parts by mass: 40 parts of seaweed, 30 parts of bamboo, 20 parts of starch, 10 parts of coconut oil, 12-16 parts of zinc stearate, 5 parts of polyvinyl alcohol, 8 parts of sodium carboxymethyl cellulose, 8 parts of glycerin, 6-9 parts of sodium bicarbonate, 5 parts of konjac glucomannan, 5 parts of carnauba wax, 3 parts of sodium citrate, 2 parts of bamboo charcoal , 3 parts of agar, 3 parts of genipin, 2 parts of polyglycerol fatty acid ester, 800 parts of water.

[0021] The preparation method of the food packaging film with antiseptic effect comprises the following steps:

[0022] (1) Clean the seaweed and bamboo with a cleaning agent, put the bamboo in a steam pot and steam for 20 minutes, mix and pulverize the seaweed and bamboo into a mixed slurry;

[0023] (2) The mixed slurry of seaweed and bamboo and coconut oil are added in the ultrasonic extract...

Embodiment 2

[0031] A food packaging film with antiseptic effect, characterized in that it is made of the following raw materials in parts by mass: 60 parts of seaweed, 50 parts of bamboo, 30 parts of starch, 15 parts of coconut oil, 16 parts of zinc stearate, polyethylene 8 parts alcohol, 12 parts carmellose sodium, 16 parts glycerin, 9 parts sodium bicarbonate, 8 parts konjac glucomannan, 8 parts carnauba wax, 5 parts sodium citrate, 5 parts bamboo charcoal, 6 parts agar , 5 parts of genipin, 3 parts of polyglycerol fatty acid ester, 1000 parts of water.

[0032] The preparation method of the food packaging film with antiseptic effect comprises the following steps:

[0033] (1) Clean the seaweed and bamboo with a cleaning agent, put the bamboo in a steam pot and steam for 30 minutes, mix and pulverize the seaweed and bamboo into a mixed slurry;

[0034] (2) The mixed slurry of seaweed and bamboo and coconut oil are added in the ultrasonic extraction tank, then adding 5 times the volume ...

Embodiment 3

[0042] A food packaging film with antiseptic effect, characterized in that it is made of the following raw materials in parts by mass: 50 parts of seaweed, 40 parts of bamboo, 25 parts of starch, 13 parts of coconut oil, 14 parts of zinc stearate, polyethylene 6 parts alcohol, 10 parts carmellose sodium, 12 parts glycerin, 8 parts sodium bicarbonate, 7 parts konjac glucomannan, 7 parts carnauba wax, 4 parts sodium citrate, 4 parts bamboo charcoal, 5 parts agar , 4 parts of genipin, 3 parts of polyglycerol fatty acid ester, and 900 parts of water.

[0043] The preparation method of the food packaging film with antiseptic effect comprises the following steps:

[0044] (1) Clean the seaweed and bamboo with a cleaning agent, put the bamboo in a steam pot and steam for 30 minutes, mix and pulverize the seaweed and bamboo into a mixed slurry;

[0045] (2) The mixed slurry of seaweed and bamboo and coconut oil are added in the ultrasonic extraction tank, then adding 5 times the volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com