Zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material and preparation as well as application thereof

A technology of thermoplastic polyurethane and sheath material, applied in the direction of conductors, insulated conductors, electrical components, etc., can solve the problems of high price, narrow processing temperature, etc., and achieve the effect of wide extrusion processing temperature and strong physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

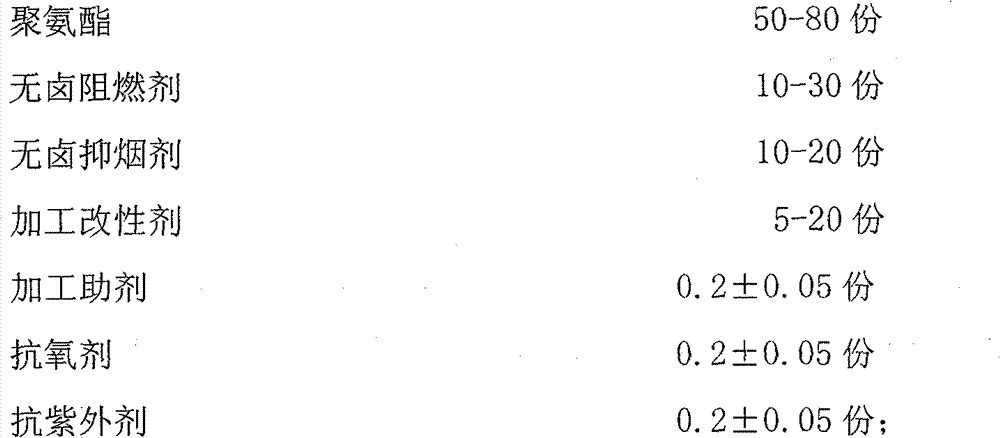

[0026] Polyurethane, halogen-free flame retardant, halogen-free smoke suppressant, processing modifier, processing aid, antioxidant and anti-ultraviolet agent, have the formula shown in Table 1, and the properties are shown in Table 2.

[0027] Table 1

[0028] raw material name

parts by weight

Polyurethane WHT-7185

60

trihydroxyhexyl cyanurate

15

Zinc borate

15

Acrylonitrile-styrene-butadiene copolymer

10

Magnesium stearate

0.2

Antioxidant KY-1076

0.2

UV-531

0.2

[0029] Preparation method: use polyurethane base material, add halogen-free flame retardant, halogen-free smoke suppressant, processing modifier, processing aid, antioxidant and anti-ultraviolet agent according to weight ratio, mix evenly, and extrude through twin-screw out of granulation. The temperature setting of the twin-screw extruder is: 140±5°C in barrel I zone, 150±5°C in barrel II zone, 160±5°C ...

Embodiment 2

[0033] Polyurethane, halogen-free flame retardant, halogen-free smoke suppressant, processing modifier, processing aid, antioxidant and anti-ultraviolet agent, have the formula shown in Table 3, and the properties are shown in Table 4.

[0034] table 3

[0035] raw material name

parts by weight

Polyurethane WHT-7185

55

[0036] FR-600

15

Zinc borate

15

Acrylonitrile-styrene-butadiene copolymer

15

Magnesium stearate

0.2

KY-1076

0.2

UV-531

0.2

[0037] Preparation method: use polyurethane base material, add halogen-free flame retardant, halogen-free smoke suppressant, processing modifier, processing aid, antioxidant and anti-ultraviolet agent according to weight ratio, mix evenly, and extrude through twin-screw out of granulation. The temperature setting of the twin-screw extruder is: 140±5°C in barrel I zone, 150±5°C in barrel II zone, 160±5°C in barrel II...

Embodiment 3

[0041] Polyurethane, halogen-free flame retardant, halogen-free smoke suppressant, processing modifier, processing aid, antioxidant and anti-ultraviolet agent, have the formula shown in Table 5, and the properties are shown in Table 6.

[0042] table 5

[0043] raw material name

parts by weight

Polyurethane WHT-7185

60

FR-600

20

[0044] magnesium hydroxide

10

Ethylene acrylic acid copolymer

10

Zinc stearate

0.2

KY-1076

0.2

UV-531

0.2

[0045] Preparation method: use polyurethane base material, add halogen-free flame retardant, halogen-free smoke suppressant, processing modifier, processing aid, antioxidant and anti-ultraviolet agent according to weight ratio, mix evenly, and extrude through twin-screw out of granulation. The temperature setting of the twin-screw extruder is: 140±5°C in barrel I zone, 150±5°C in barrel II zone, 160±5°C in barrel III zone,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com