Preparation technology allowing large-scale production of flexible biomass-based pressure sensors

A technology of pressure sensor and preparation process, which is applied in the field of wearable sensing, can solve the problems of incapable of large-scale production and high production cost, and achieve the effects of strong physical and mechanical properties, simplified production process, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

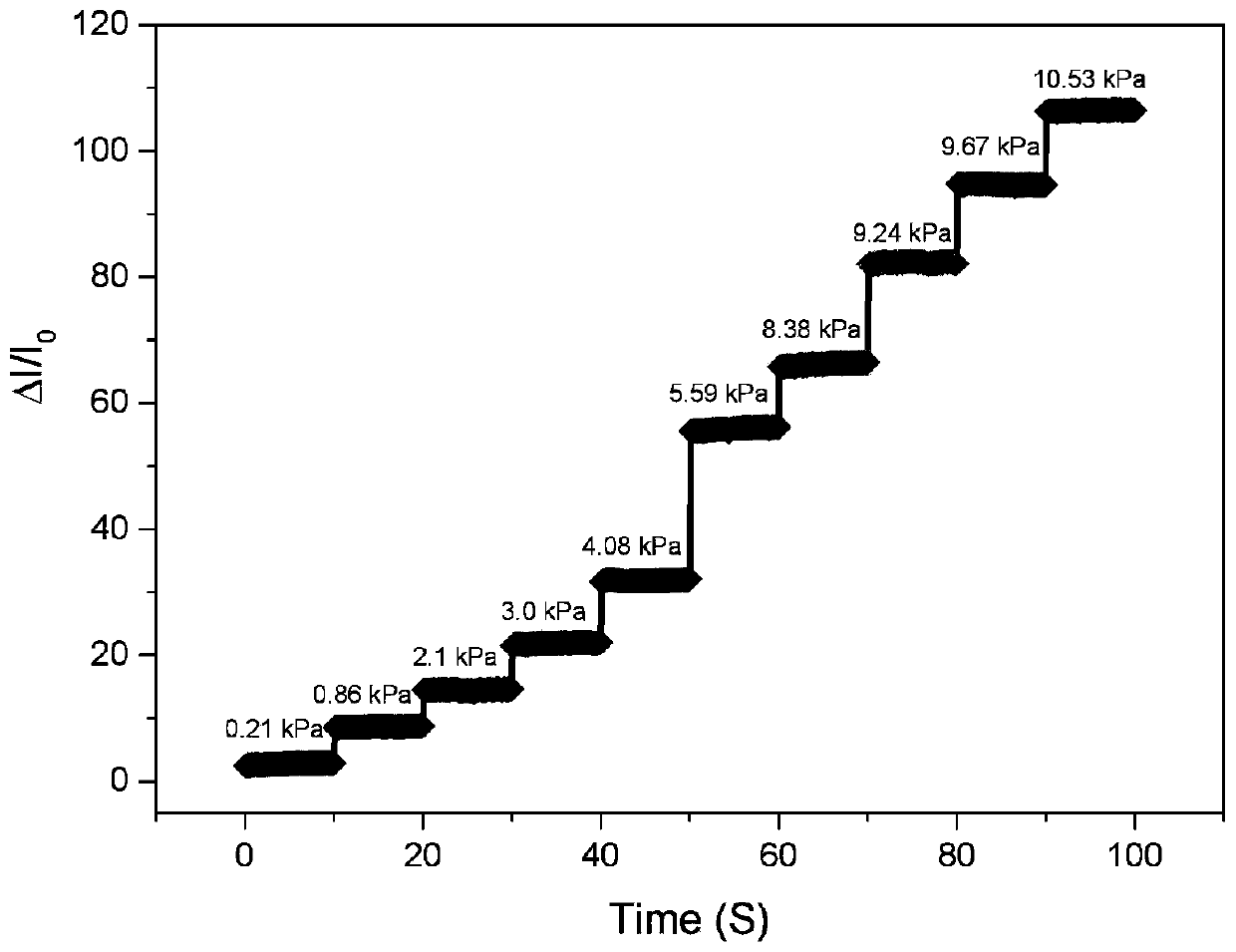

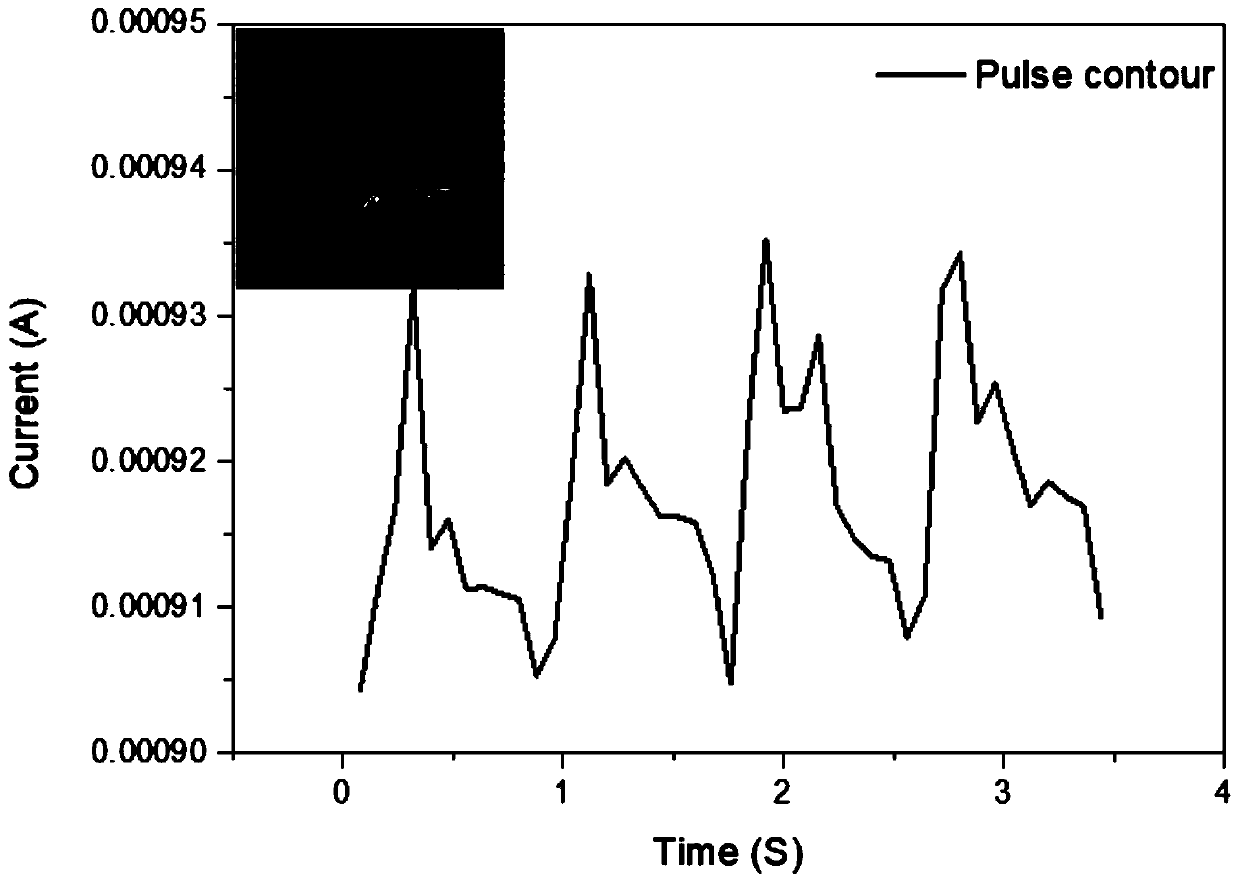

Image

Examples

Embodiment 1

[0025] Example 1: In this example, the PDMS / n-hexane solution is configured using Dow Corning SYLGUARD184 silicone rubber, model Sylgard 184. Dow Corning SYLGUARD184 silicone rubber is composed of separately packaged main agent SYLGUARD-184A and hardener SYLGUARD-184B.

[0026] The preparation process of the flexible biomass-based pressure sensor that can be mass-produced in this embodiment is carried out according to the following steps:

[0027] Step 1. Put the raw cotton into a corundum crucible after being pressed into pieces, and then place it in a tube furnace, and carbonize it at 900°C for 2 hours in a high-purity argon (mass purity: 99.999%) atmosphere;

[0028] Step 2, then cut into a rectangle with an area of 1.9cm×1.2cm and a thickness of 7±0.5mm;

[0029] Step 3, then soak in PDMS / n-hexane solution for 20 minutes, take it out, hang it in an oven at 80°C in a way similar to drying clothes, until it solidifies, and obtain a flexible biomass-based pressure sensor; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com