Preparation method of silica aerogel under atmospheric pressure

A silicon dioxide and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of gel cracking, complex preparation process, limited extensiveness, etc., to reduce surface tension and simplify the process. The effect of reducing and reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Preparation of silica airgel

[0045] The preparation method of the silica airgel of embodiment 1 of the present invention comprises the following steps:

[0046] (1) Add tetraethyl orthosilicate, absolute ethanol and deionized water into the container, and mix and stir for 10 min according to molar ratio, tetraethyl orthosilicate: absolute ethanol: deionized water at 1:12:6; Add 1 mol / L hydrochloric acid, adjust the pH to 2, stir and hydrolyze for 1.5 hours to obtain silica sol;

[0047](2) Add 0.446 mol / L ammonia water to the above silica sol, slowly add drop by drop and stir while adding, adjust the pH to 7, and wait for it to gel at room temperature until the container is tilted more than 45° , until the liquid level in the container does not tilt;

[0048] (3) Put the gel in a plastic or glass container, add tetraethyl orthosilicate in a volume ratio of 1:4 to the mother liquor for aging, seal it and leave it at room temperature for aging for 24 hours; ...

Embodiment 2

[0062] Example 2 Preparation of silica airgel

[0063] The preparation method of the silica airgel of the embodiment 2 of the present invention comprises the following steps:

[0064] (1) Add methyl orthosilicate, absolute ethanol and deionized water into the container, and mix and stir for 20 min in a molar ratio of methyl orthosilicate: absolute ethanol: deionized water at 1:5:1; Add 4 mol / L hydrochloric acid, adjust the pH to 2.5, stir and hydrolyze for 2 hours to obtain silica sol;

[0065] (2) Add 1 mol / L ammonia water to the above-mentioned silica sol, add drop by drop slowly and stir while adding, adjust the pH to 7.5, and wait for it to gel at room temperature until the container is tilted more than 45° , until the liquid level in the container does not tilt;

[0066] (3) Put the gel in a plastic or glass container, add tetraethyl orthosilicate in a volume ratio of 1:4 to the mother liquor for aging, seal it and leave it at room temperature for aging for 24 hours;

...

Embodiment 3

[0071] Example 3 Preparation of silica airgel

[0072] The preparation method of the silica airgel of embodiment 3 of the present invention comprises the following steps:

[0073] (1) Add methyltrimethoxysilane, absolute ethanol and deionized water into the container, in molar ratio, methyltrimethoxysilane: absolute ethanol: deionized water is 1:7:3, mix and stir for 15 min ; Then add 1 mol / L hydrochloric acid to adjust the pH to 3, stir and hydrolyze for 3 hours to obtain silica sol;

[0074] (2) Add 0.446mol / L ammonia water to the above silica sol, add drop by drop slowly and stir while adding, adjust the pH to 8, and wait for it to gel at room temperature until the container is tilted over 45° , until the liquid level in the container does not tilt;

[0075] (3) Put the gel in a plastic or glass container, add tetraethyl orthosilicate in a volume ratio of 1:4 to the mother liquor for aging, seal it and leave it at room temperature for aging for 24 hours;

[0076] (4) Pla...

PUM

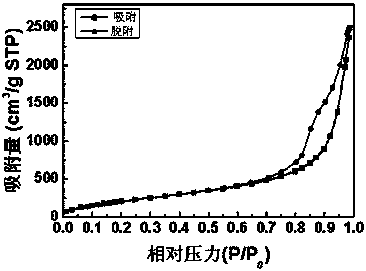

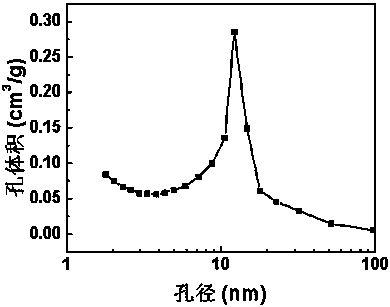

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com