Magnetized CCP (Capacitively Coupled Plasma) source driven by RF and DC mixedly

A plasma source and plasma technology, applied in the field of plasma discharge, can solve problems such as low plasma density, and achieve the effects of increasing plasma density, ensuring feasibility, and reducing improvement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

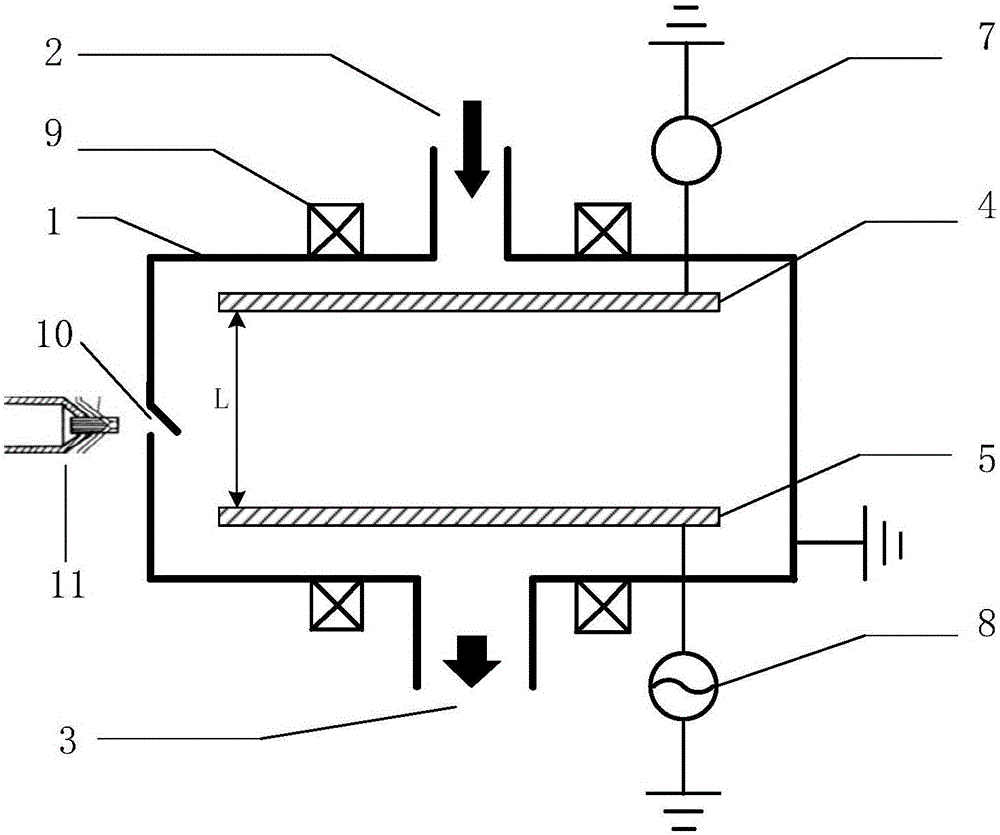

[0031] Example 1: Reference image 3 The structure; the hydrogen gas is introduced into the plasma chamber 1, the air pressure is controlled within the range of 10mTorr to 1Torr, the first pole plate 4 is connected to the negative DC power supply 7, the second pole plate 5 is connected to the radio frequency power supply 8, the chamber or side The walls are grounded, and energized coils or permanent magnets are placed outside the chamber to generate a magnetic field parallel to the plates. Gas discharge under the action of direct current and magnetic field can generate a large amount of hydrogen ions. Open the side wall opening 10, connect the extraction electrode 11, and extract the ion beam current from the chamber. This ion source can be widely used in various types of ion accelerators, mass spectrometers, electromagnetic isotope separators, ion implanters, ion beam engraving Erosion devices, ion thrusters, and neutral beam injectors in controlled fusion devices.

example 2

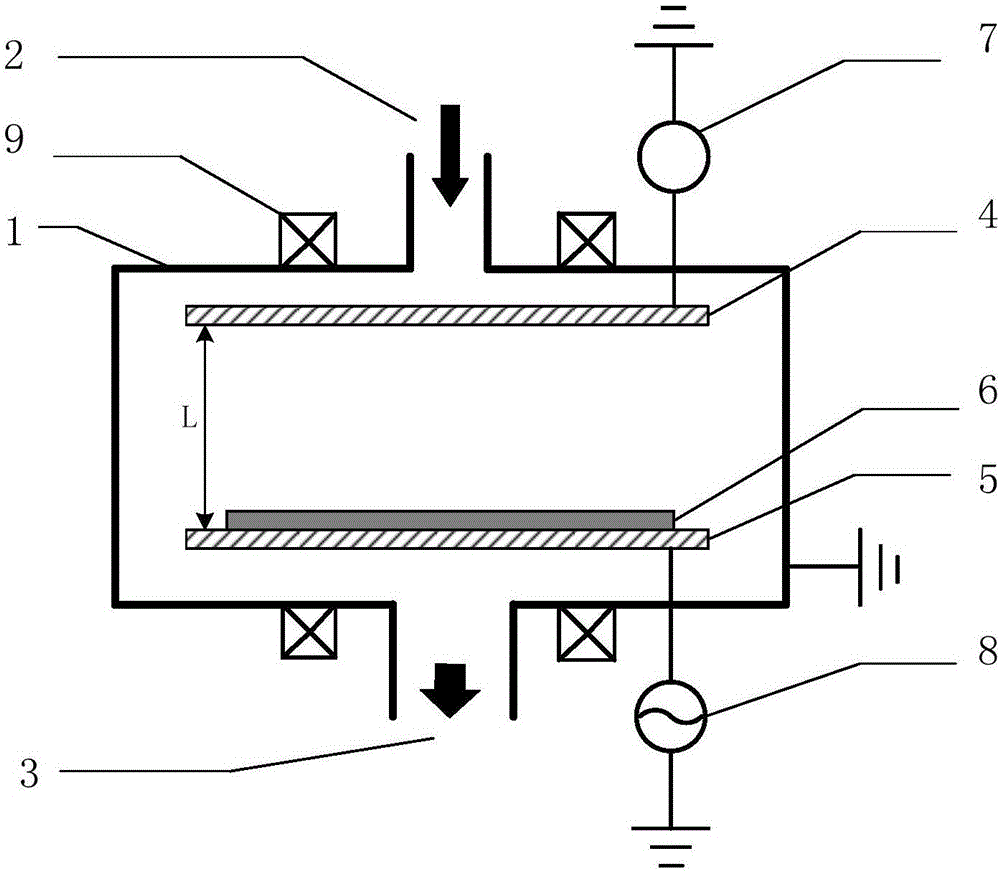

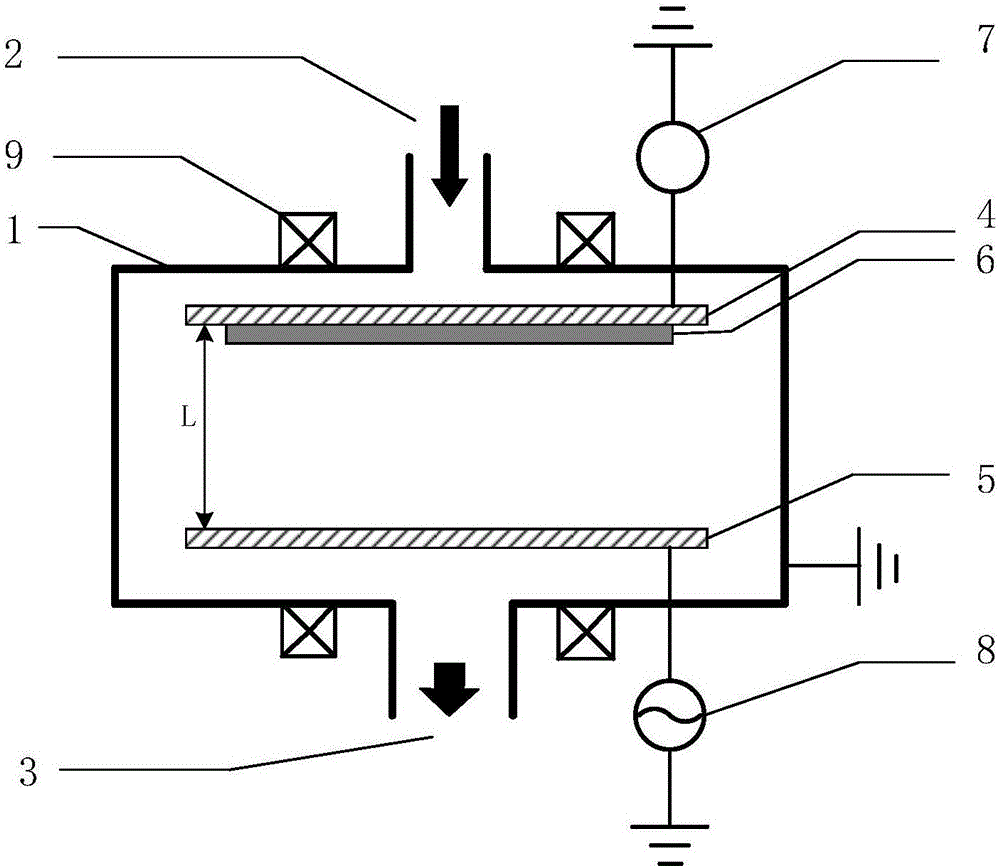

[0032] Example 2: Reference figure 1 The structure; in the plasma chamber 1, fluorocarbon gas (such as carbon tetrafluoride), a mixed gas of oxygen and argon is introduced, and the air pressure is controlled in the range of about 10mTorr–100mTorr, and the first electrode plate 4 is connected to a negative direct current Power supply 7, the second pole plate 5 is connected to the radio frequency power supply 8, the substrate 6 is placed on the second pole plate 5, the chamber or the side wall is grounded, and an energized coil or permanent magnet 9 is placed outside the chamber to generate a magnetic field parallel to the pole plate. magnetic field. The high-density plasma source generated by mixed gas discharge can meet the requirements of etching manufacturing processes such as MEMS. MEMS usually uses polysilicon as the main material. This plasma source can provide a high etching rate.

example 3

[0033] Example 3: Reference figure 1 The structure; silane is passed into the plasma chamber 1, the air pressure is controlled within the range of 300mTorr–1Torr, the first plate 4 is connected to the negative DC power supply 7, the second plate 5 is connected to the radio frequency power supply 8, and the substrate 6 is placed On the second pole plate 5 , the chamber or side wall is grounded, and an energized coil or permanent magnet 9 is placed outside the chamber to generate a magnetic field parallel to the pole plate. The generated high-density and energy-controllable plasma source can be used for plasma thin film deposition, and this technology is widely used in large-scale production of amorphous silicon thin-film photovoltaic solar cells, thin-film transistors for flat panel displays and other industries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com