Multiple functionality degree polysiloxane coupling agent and preparation method thereof

A polysiloxane coupling agent and a multifunctional technology, which is applied in the field of polyfunctional polysiloxane coupling agent and its preparation, can solve the problems of poor bonding effect of the coupling agent, and achieve good surface treatment effect. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

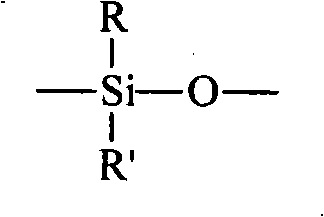

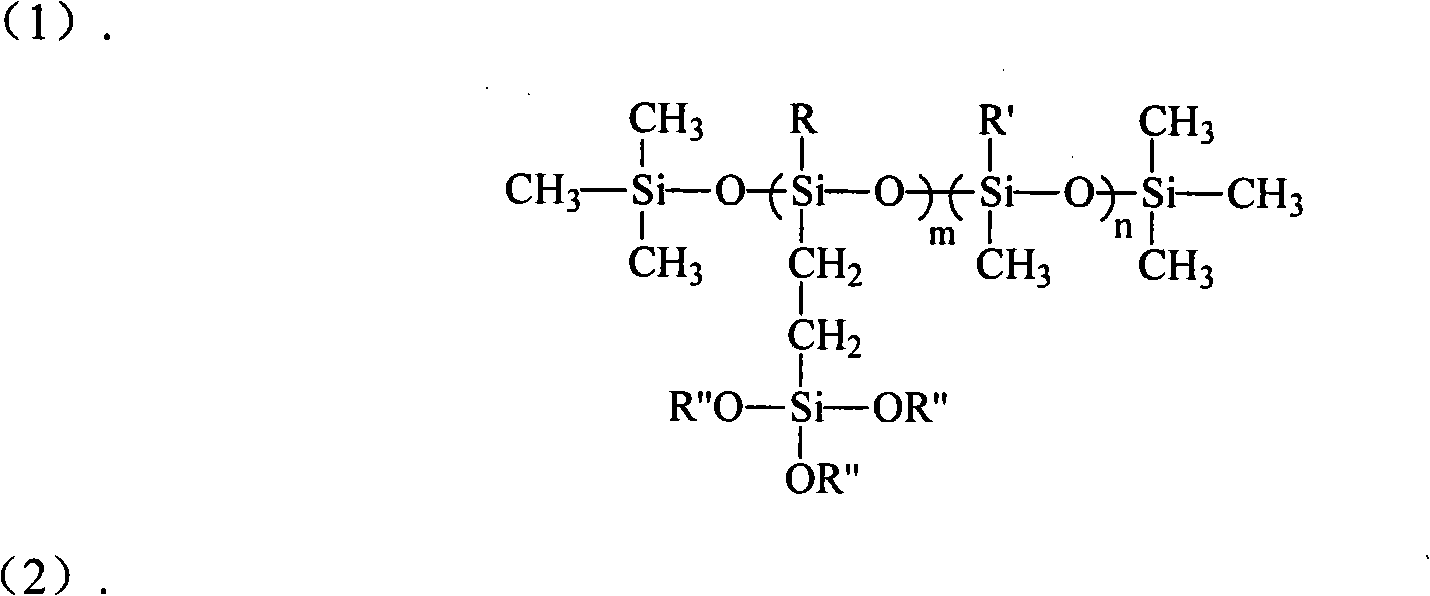

[0028]In a 500ml three-necked flask equipped with a reflux device and a drying device, add 60 grams (0.01mol) of dry polymethylhydrogensiloxane (Mn=6000, Xn=100) and dry 100 grams of toluene, and then add 0.067 Grams of [Pt(C 2 h 2 ) 2 Cl 2 ] 2 , 73 g (0.5 mol) of vinyltrimethoxysilane was added dropwise, and reacted at 100° C. for 10 hours to obtain a colorless transparent solution. The transparent solution was distilled under reduced pressure to obtain a polysiloxane coupling agent product, and after hydrogen 1 H nuclear magnetic resonance spectrum characterization (chemical shift: 4.7ppm, 3.54ppm, 1.08ppm, 0.55ppm, 0.18ppm, 0.10ppm), its structure is as follows:

[0029]

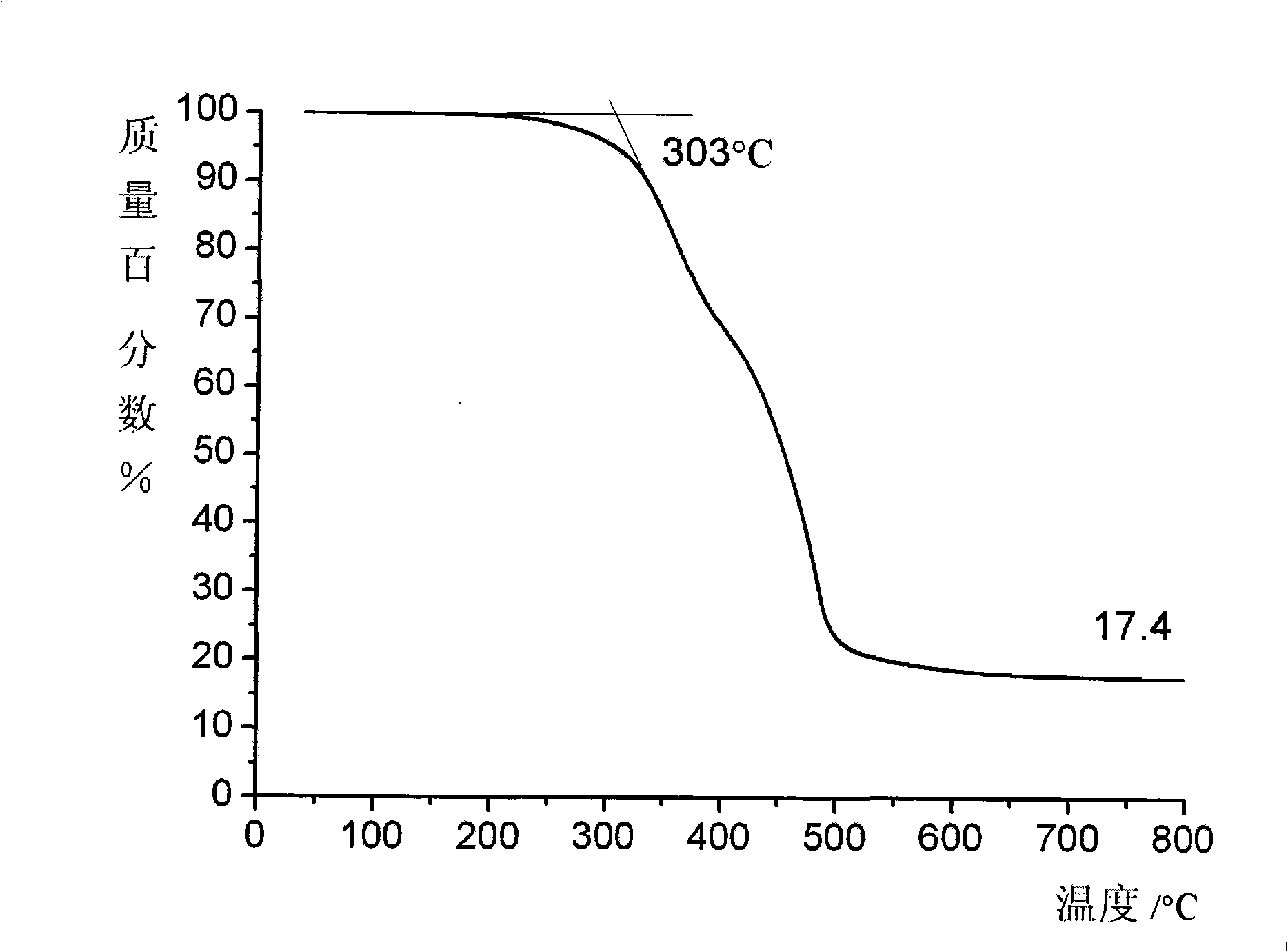

[0030] Accompanying drawing is the thermal weight loss figure of this coupling agent in nitrogen atmosphere. It can be known that the starting decomposition temperature of this coupling agent is 303°C; at 800°C, the mass retention rate is 17.4%. It can be seen that the coupling agent prepared by...

Embodiment 2

[0032] In the 500ml three-neck flask equipped with reflux device and drying device, add 86 grams (0.01mol) of dry polymethylvinylsiloxane (Mn is about 8600, Xn=100) and dry 100 grams of n-hexane, Then add 0.10 g of H 2 PtCl 6 ·6H 2 O isopropanol solution (mass concentration: 2%), 49.20 g (0.3 mol) of triethoxyhydrosilane was added dropwise, and reacted at 50° C. for 8 hours to obtain a colorless transparent solution. The transparent solution was distilled under reduced pressure to obtain a polysiloxane coupling agent product, and after hydrogen 1 H NMR spectrum characterization, its structure is as follows:

[0033]

Embodiment 3

[0035] In a 250ml three-necked flask equipped with a reflux device and a drying device, add 66.6 grams (0.01mol) of dry vinyl-terminated polydimethylsiloxane (Mn about 6660, Xn=90) and dry 50 grams of n-hexane , followed by adding 3.28 grams of triethoxyhydrosilane (0.02mol) and 0.07 grams of [Pt(C 2 h 2 ) 2 Cl 2 ] 2 , and reacted at 60°C for 8 hours to obtain a colorless and transparent solution. The transparent solution was distilled under reduced pressure to obtain a polysiloxane coupling agent product, and after hydrogen 1 H NMR spectrum characterization, its structure is as follows:

[0036]

[0037] The polyfunctionality polysiloxane prepared in this embodiment, because the end group contains three alkoxy groups, so the surface treatment effect on the inorganic powder filler is better than that of the polyfunctional polysiloxane prepared by the patent application CN1165533 with only one alkoxy group per chain segment. Polysiloxane has a better surface treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com