Corona discharge based carbon fiber surface treatment device and method

A technology of surface treatment and corona discharge, which is applied in the direction of ultrasonic/sonic fiber treatment, etc., can solve the problems of high modulus carbon fiber treatment, such as ineffective treatment, failure to meet performance requirements, loss of carbon fiber strength, etc., to achieve large elastic space, carbon fiber Less strength loss and improved shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

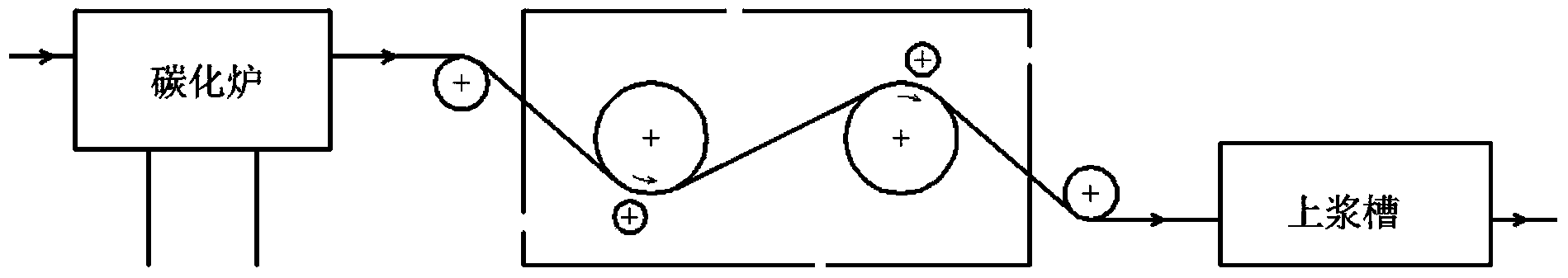

[0032] The carbon fiber corona discharge surface treatment process is arranged after the carbonization process of carbon fiber production, such as figure 1 As shown, there is residual heat after the carbon fiber comes out of the carbonization furnace, and the carbon fiber is subjected to corona discharge surface treatment at a position where the carbon fiber temperature is 120 °C; the carbon fiber enters the sizing tank for sizing after the corona discharge surface treatment.

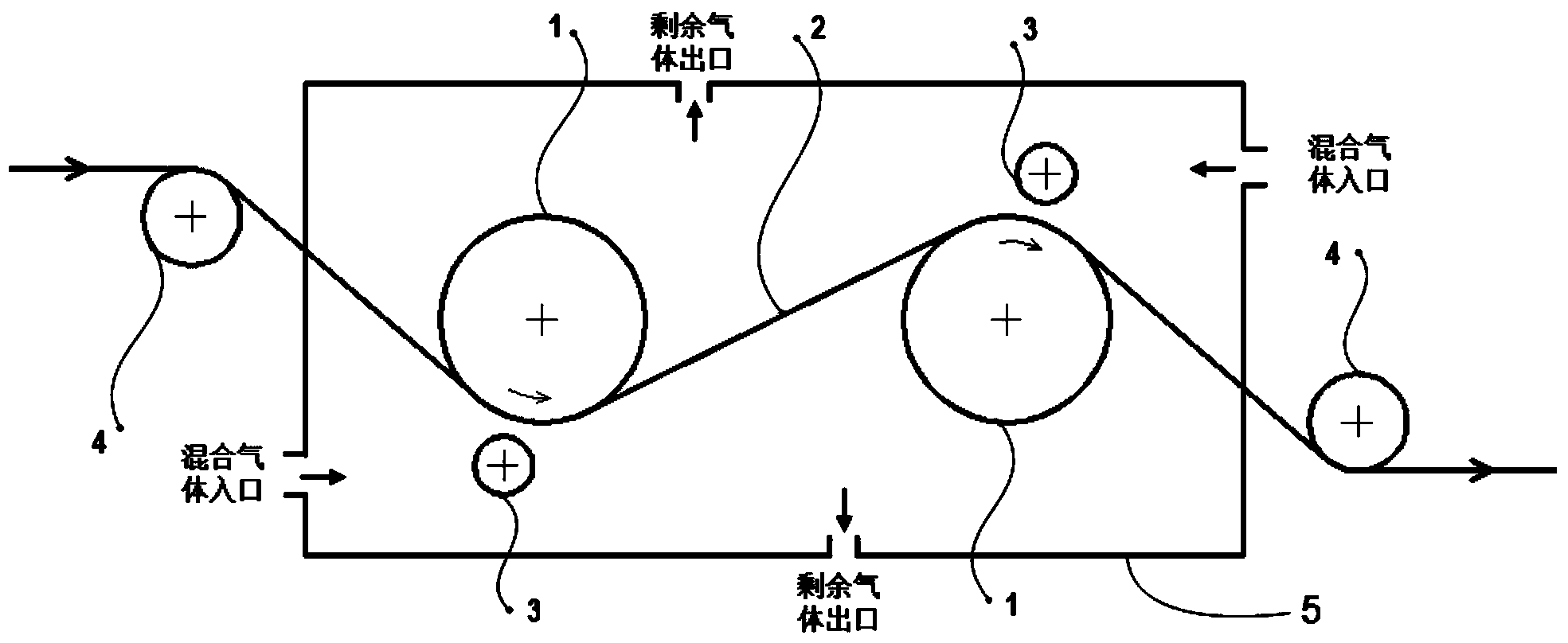

[0033] figure 2 It is a schematic structural diagram of a device for corona discharge-based carbon fiber surface treatment. Such as figure 2 As shown, the device for surface treatment of carbon fibers based on corona discharge includes a large roller 1 , carbon fibers 2 , small rollers 3 , auxiliary rollers 4 and a surface treatment chamber 5 . There are two sets of corona discharge devices inside the surface treatment chamber 5, and the corona discharge devices are composed of a large roller 1 and ...

Embodiment 2

[0039] The carbon fiber corona discharge surface treatment process is arranged after the carbonization process of carbon fiber production, such as figure 1 As shown, there is residual heat after the carbon fiber comes out of the carbonization furnace, and the carbon fiber is subjected to corona discharge surface treatment at a position where the carbon fiber temperature is 90 °C; the carbon fiber enters the sizing tank for sizing after the corona discharge surface treatment.

[0040] figure 2 It is a schematic structural diagram of a device for corona discharge-based carbon fiber surface treatment. Such as figure 2 As shown, the device for surface treatment of carbon fibers based on corona discharge includes a large roller 1 , carbon fibers 2 , small rollers 3 , auxiliary rollers 4 and a surface treatment chamber 5 . There are two sets of corona discharge devices inside the surface treatment chamber 5, and the corona discharge devices are composed of a large roller 1 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com