High-pollution-resistance type polyvinylidene fluoride (PVDF) hollow fiber ultrafiltration membrane, preparation method and device

A polyvinylidene fluoride, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of high PVDF membrane strength, large membrane pore size, wide pore size distribution, etc., and achieve good integrity and asymmetry. , the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

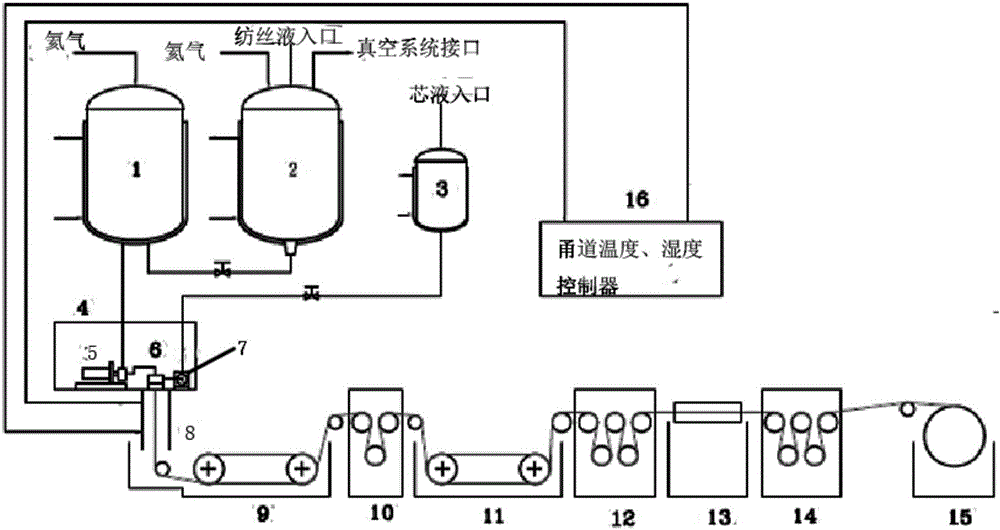

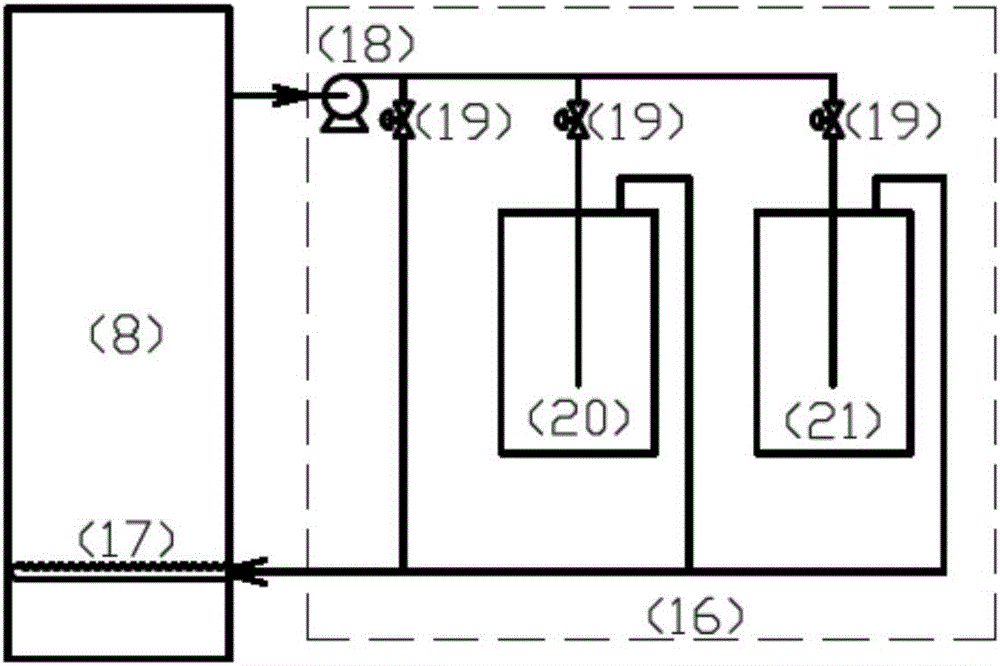

[0086]Two polyvinylidene fluoride resins with different weight average molecular weights, Solvay 1010 and HSV 900, are selected for blending. The total amount of resin is 19% of the total weight of the casting solution, and the two resins are mixed in a ratio of 3:7. The solvent was dimethylacetamide (DMAC) at 52%. Polyvinylpyrrolidone (PVP) K17 is used as a polymer hydrophilic thickener with a content of 14%. Non-solvents are PEG400 and glycerol. PEG 400 accounts for 10%. Glycerin consumption is 5%. The above substances are put into the mixing tank in the order of first liquid and then solid, first small molecular weight and then large molecular weight, and stir at 75-80°C to form a uniform dark yellow casting liquid. The viscosity of the casting liquid is 28000 centipoise (80°C) . After the dissolution is complete, transfer it to a degassing tank at the same temperature for degassing. The gear metering pump squeezes the completely degassed casting solution out of the spi...

Embodiment 2

[0090] Two polyvinylidene fluoride resins with different weight average molecular weights, Solvay 1010 and HSV 900, are selected for blending. The total amount of resin is 19% of the total weight of the casting solution, and the two resins are mixed in a ratio of 3:7. The solvent was dimethylacetamide (DMAC) at 52%. Polyvinylpyrrolidone (PVP) K17 is used as a polymer hydrophilic thickener with a content of 14%. Non-solvents are PEG400 and glycerin. PEG 400 accounts for 10%. Glycerin consumption is 5%. The above substances are put into the mixing tank in the order of first liquid and then solid, first small molecular weight and then large molecular weight, and stir at 75-80°C to form a uniform dark yellow casting liquid. The viscosity of the casting liquid is 28000 centipoise (80°C) . After the dissolution is complete, transfer it to a degassing tank at the same temperature for degassing. The gear metering pump squeezes the completely degassed casting solution out of the sp...

Embodiment 3

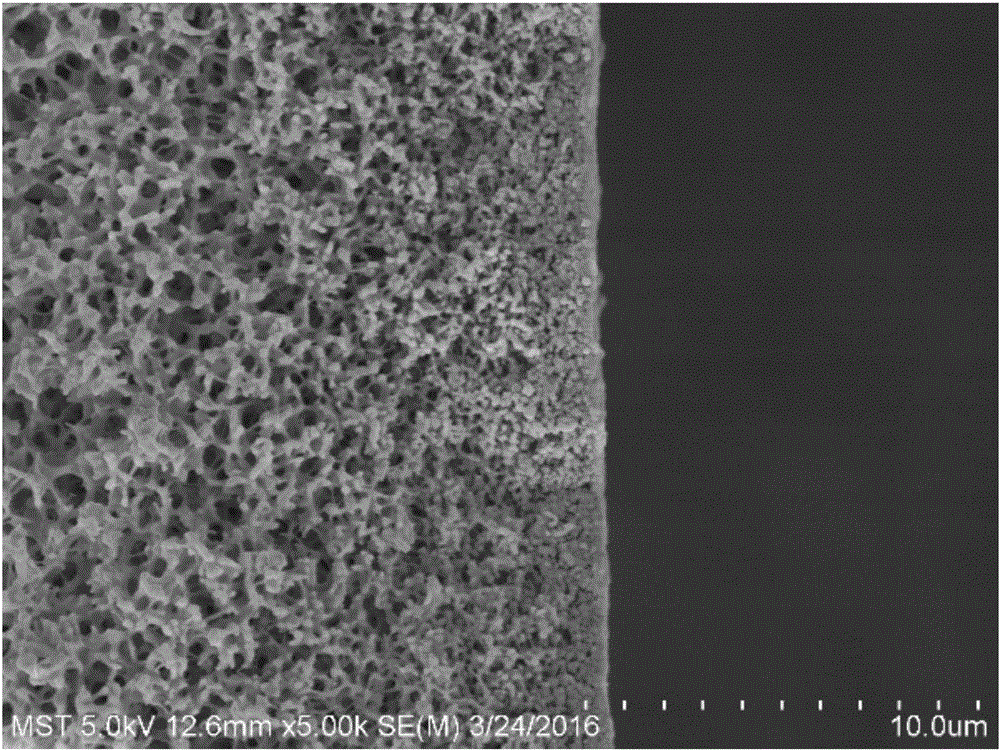

[0092] Two polyvinylidene fluoride resins with different weight-average molecular weights, FR 904 and solvay 1015, were selected for blending. The total amount of the resin was 19% of the total weight of the casting solution, and the two resins were mixed in a ratio of 8:2. The solvent was dimethylacetamide (DMAC) at 56%. Polyvinylpyrrolidone (PVP) K30 is used as a polymer hydrophilic thickener with a content of 12%. Non-solvents are PEG400 and glycerin. PEG 400 accounts for 8%. Glycerin consumption is 5%. The above substances are put into the mixing tank in the order of first liquid and then solid, first small molecular weight and then large molecular weight, and stir at 75-80°C to form a uniform dark yellow casting solution. The viscosity of the casting solution is 29000 centipoise (80°C) . The spinning process is as example 2. The tensile force of the dried membrane filament is 4.1 Newton. When using 1g / L BSA solution to characterize its anti-pollution ability, the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com