Semi-conductor type single-walled carbon nano tube and preparation method thereof

A single-wall carbon nanotube and semiconductor technology, which is applied in the field of carbon nanotubes to achieve the effects of simple equipment, strong repeatability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Bulk phase growth of semiconducting single-walled carbon nanotubes of the present invention

[0036] The present embodiment method comprises the following steps:

[0037] 1. Preparation of catalyst

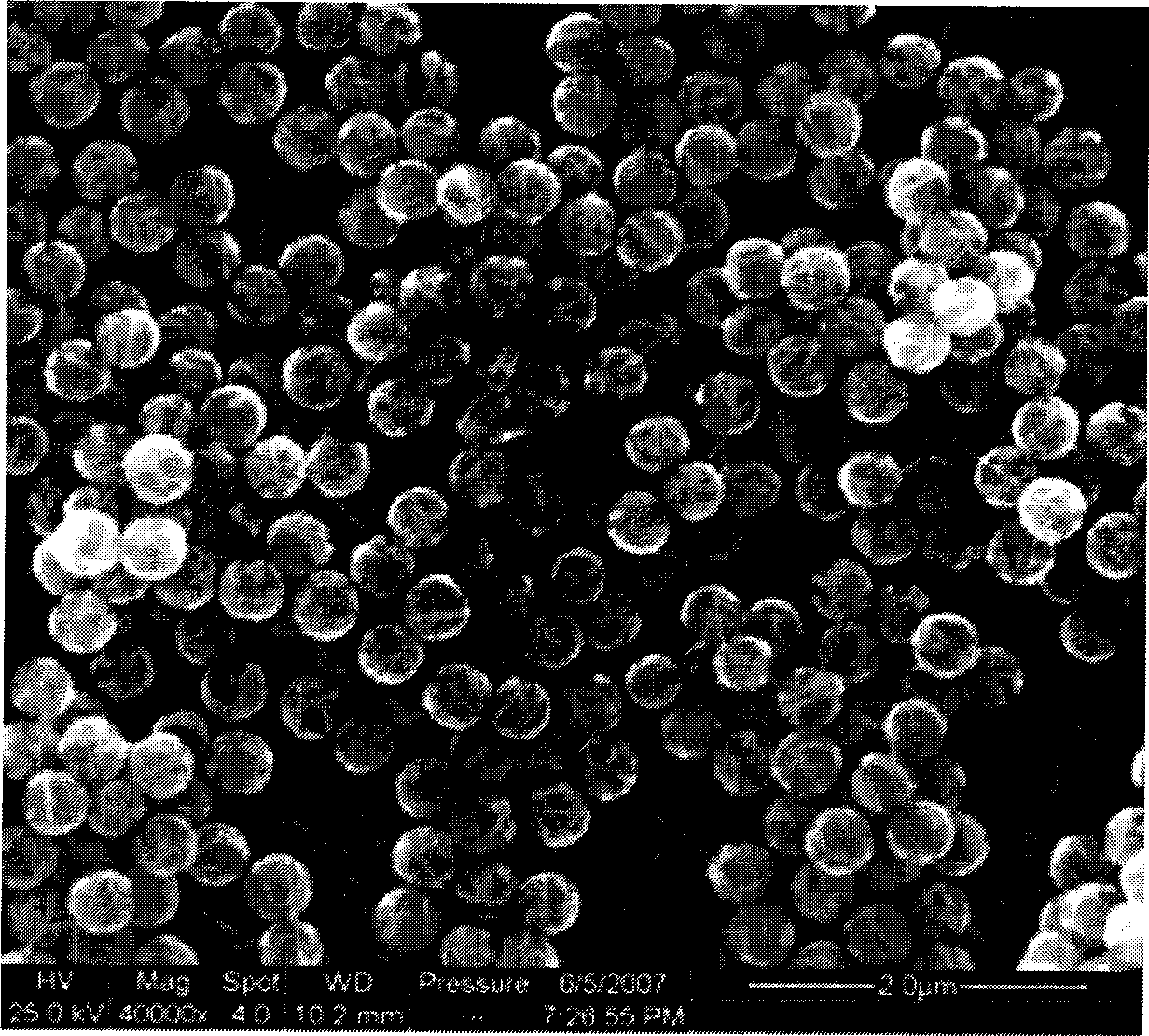

[0038] with FeCl 3 / EtOH solution acts as a catalyst precursor with a concentration of 1mmol / L. The selected carrier includes silica microspheres (about 400nm in particle size) and porous magnesia. Soak 0.05g of carrier powder in 20ml of the above-mentioned FeCl 3 / EtOH solution for 30 minutes, centrifuge to discard the liquid part, and dry the solid powder at 70°C;

[0039] The reaction chamber is sealed, and argon gas is introduced to exhaust the air;

[0040] The temperature was raised to 900°C, and 100 sccm of hydrogen gas was used to reduce the catalyst particles for 20 minutes;

[0041] 2. Chemical vapor deposition

[0042] Keep the temperature constant, turn off the hydrogen used for reduction, and change it to 800-1000 sccm argon to act as a dilue...

Embodiment 2

[0046] Embodiment 2: Surface Random film growth of semiconducting single-walled carbon nanotubes of the present invention

[0047] This embodiment adopts the same device and steps as in Example 1, the difference is that the substrate is replaced with a silicon wafer with a 400nm thick oxide layer, and the catalyst precursor solution is dropped on the substrate and dried quickly so that it is evenly covered on the silicon wafer. A thin film of catalyst particles was formed on the surface of the sheet.

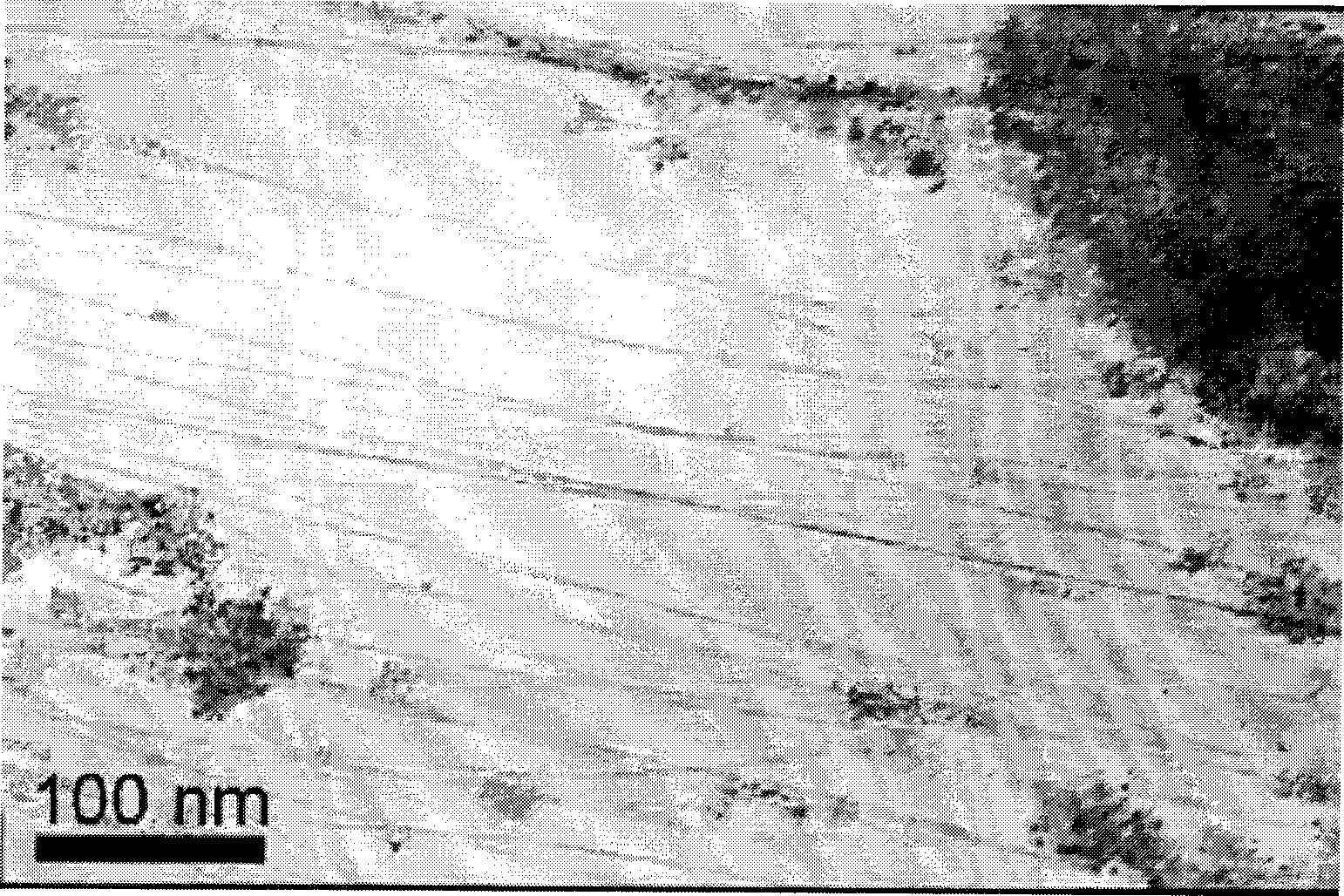

[0048] The scanning electron micrograph of the semiconductor-type single-walled carbon nanotube obtained in the present embodiment is as attached Figure 4 As shown, the XPS spectrum is as Image 6 As shown, the Raman spectrum is shown as Figure 7 As shown, its RBM is located at 157.3cm -1 , is a single-walled carbon nanotube with a diameter of about 1.6nm. The height of the D Band peak is not high, which shows that a good quality single-walled carbon nanotube film can be o...

Embodiment 3

[0049] Example 3: Surface Oriented Array Growth of Semiconducting Single-walled Carbon Nanotubes of the Present Invention

[0050] 1. Preparation of catalyst

[0051] Catalyst is prepared according to the same method as in Example 1, the difference is that the catalyst precursor solution is applied to the front end of the silicon chip;

[0052] 2. Chemical vapor deposition

[0053] Then keep the temperature constant, turn off the hydrogen used for reduction, and change it into 800-1000 sccm argon to serve as a diluent gas;

[0054] Pull the reaction area out of the constant temperature area for 5 minutes, so that the temperature of the reaction area is about 300°C different from the constant temperature area in the furnace; introduce the pyridine vapor generated by bubbling 10.0 sccm of hydrogen into the reaction system, and pull the reaction area back to the constant temperature in the furnace Zone, 900°C constant temperature for 15 minutes; during the reaction process, pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com