Multifunctional standard gas generator

A standard gas and generating device technology, applied in gas generating devices, preparation of test samples, chemical instruments and methods, etc., can solve the problems of high process and operation requirements, unattainable, poor reproducibility, etc., and achieve gasification efficiency High, short stabilization time, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

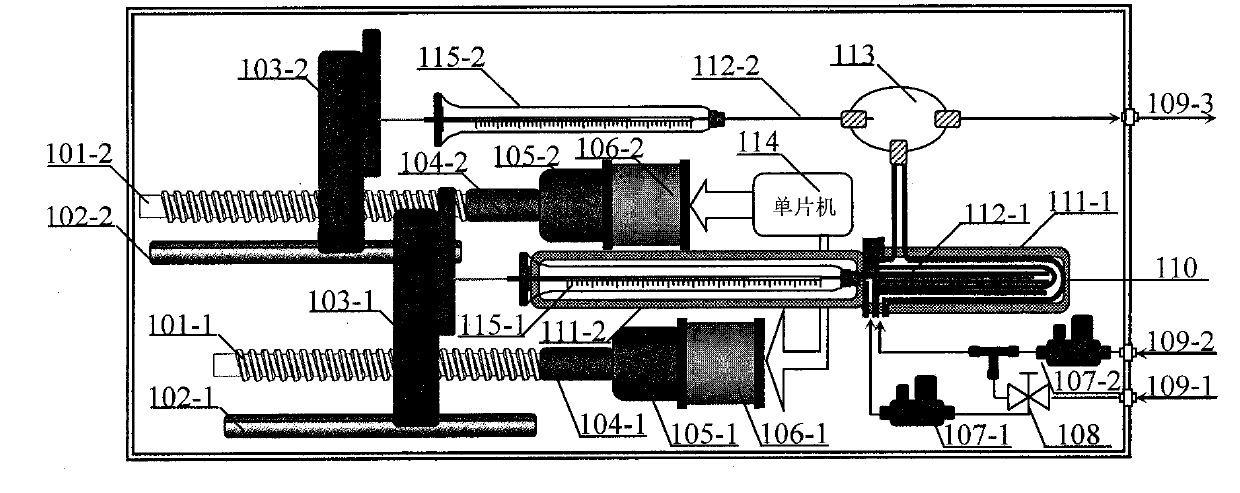

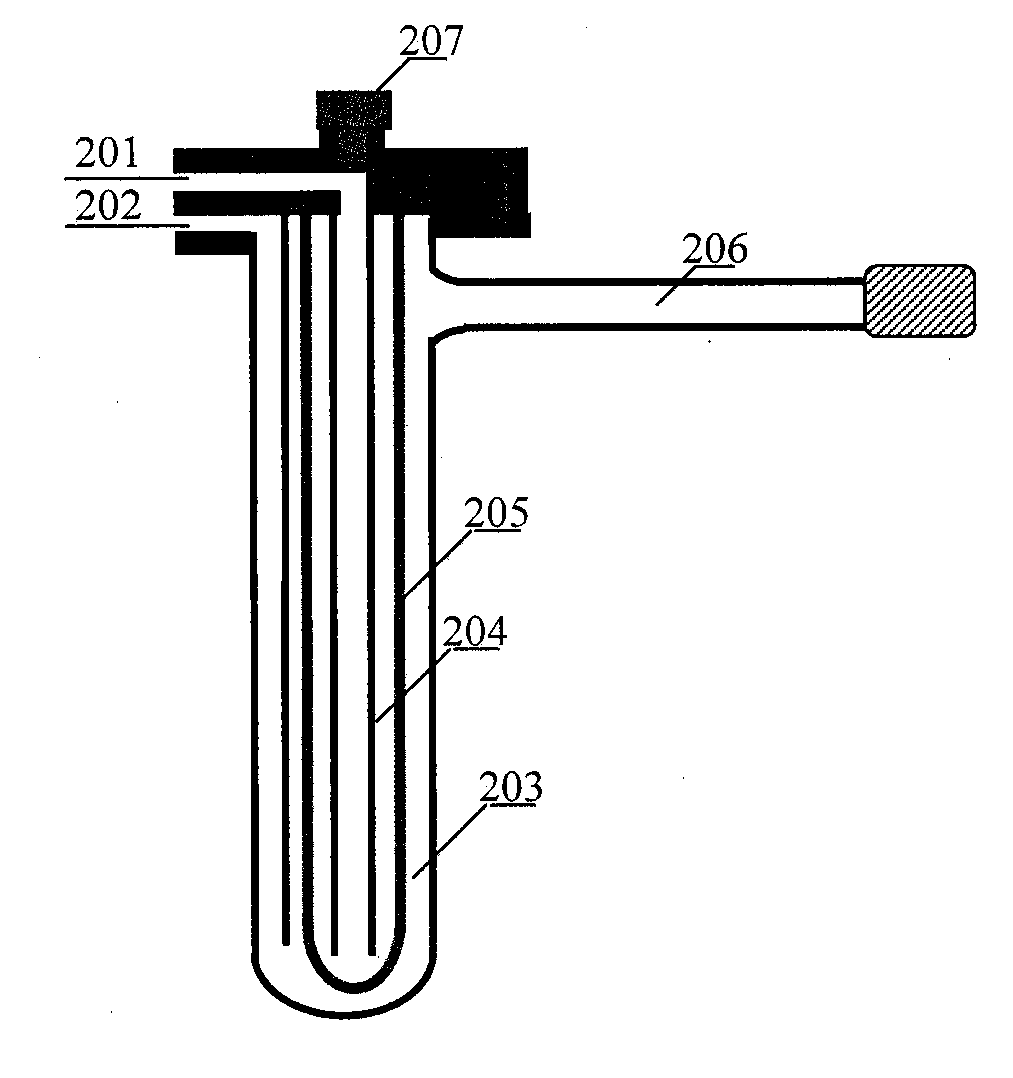

Method used

Image

Examples

Embodiment 1

[0050] Set the temperature of the first syringe to 40°C and the gas flow to 200mL min -1 , absolute ethanol (40°C density 0.7722g·mL -1 ) The output concentrations of standard substances (assumed to be 100% pure) are 0.0750 and 0.1500 mg·L respectively -1 . Connect the multifunctional standard gas generating device to the breath alcohol content detector (fuel cell electrochemical detector), and the average value of the 10 breaths displayed by the detector is 0.0650 and 0.1409mg·L respectively -1 .

Embodiment 2

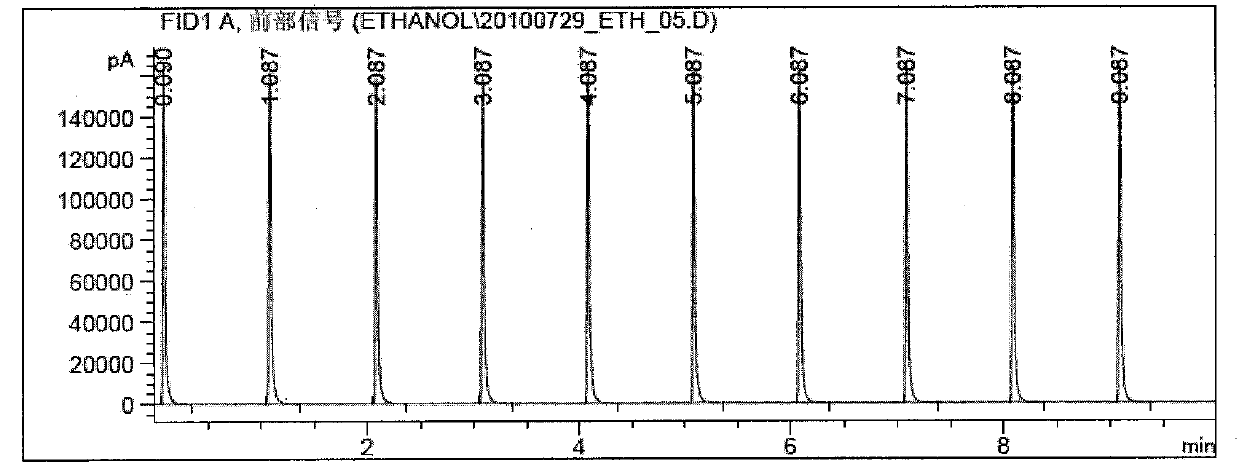

[0052] The standard gas outlet prepared by the multifunctional standard gas generating device of the present invention is connected with the gas chromatograph inlet through the six-way valve, and the gas chromatography conditions are set so that the six-way valve is opened every minute. Set the temperature of the first syringe to 40°C, and the gas flow to 100, 200mL min -1 , absolute ethanol (40°C density 0.7722g·mL -1 ) The output concentration of the standard substance (assuming that the purity is 100%) is 0.0750mg L -1 . Start the gas chromatography to get image 3 and Figure 4 The chromatograms, the average peak areas were 195217.4, 190262.0, the relative standard deviations were 2.04%, 1.56%, respectively, and the relative standard deviation between the two was 1.29%.

Embodiment 3

[0054] The standard gas outlet prepared by the multifunctional standard gas generating device of the present invention is connected with the gas chromatograph inlet through the six-way valve, and the gas chromatography conditions are set so that the six-way valve is opened every minute. Set the temperature of the first syringe to 40°C and the gas flow to 100mL min -1 , benzene (the relationship between density p and temperature t°C: p=0.90005-1.0638×10 -3 t-0.0376×10 -6 t 2 -2.213×10 -9 t 3 , g·mL -1 ) The output concentrations of standard substances (assumed to be 100% pure) are 100, 500, 1000, 3000, 5000 mg·m -3 . Start the gas chromatography, take the average value of the chromatographic peak area of each group as the ordinate, and the benzene output concentration as the abscissa, to obtain Figure 5 Dependence on Benzene Concentration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com