System and method for performing single-side continuous chemical wet treatment by using mist chemical agent

A chemical agent, wet treatment technology, applied in chemical/physical/physicochemical nozzle reactors, injection devices, electrical components, etc., can solve the problem that synthetic agents cannot exist in their vapor or gas, and chemical wet treatment cannot be used Synthetic agents, accelerated substrate surface damage and other issues, to achieve the effect of saving chemical liquid and deionized water, huge process and flexible production of products, and increasing production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

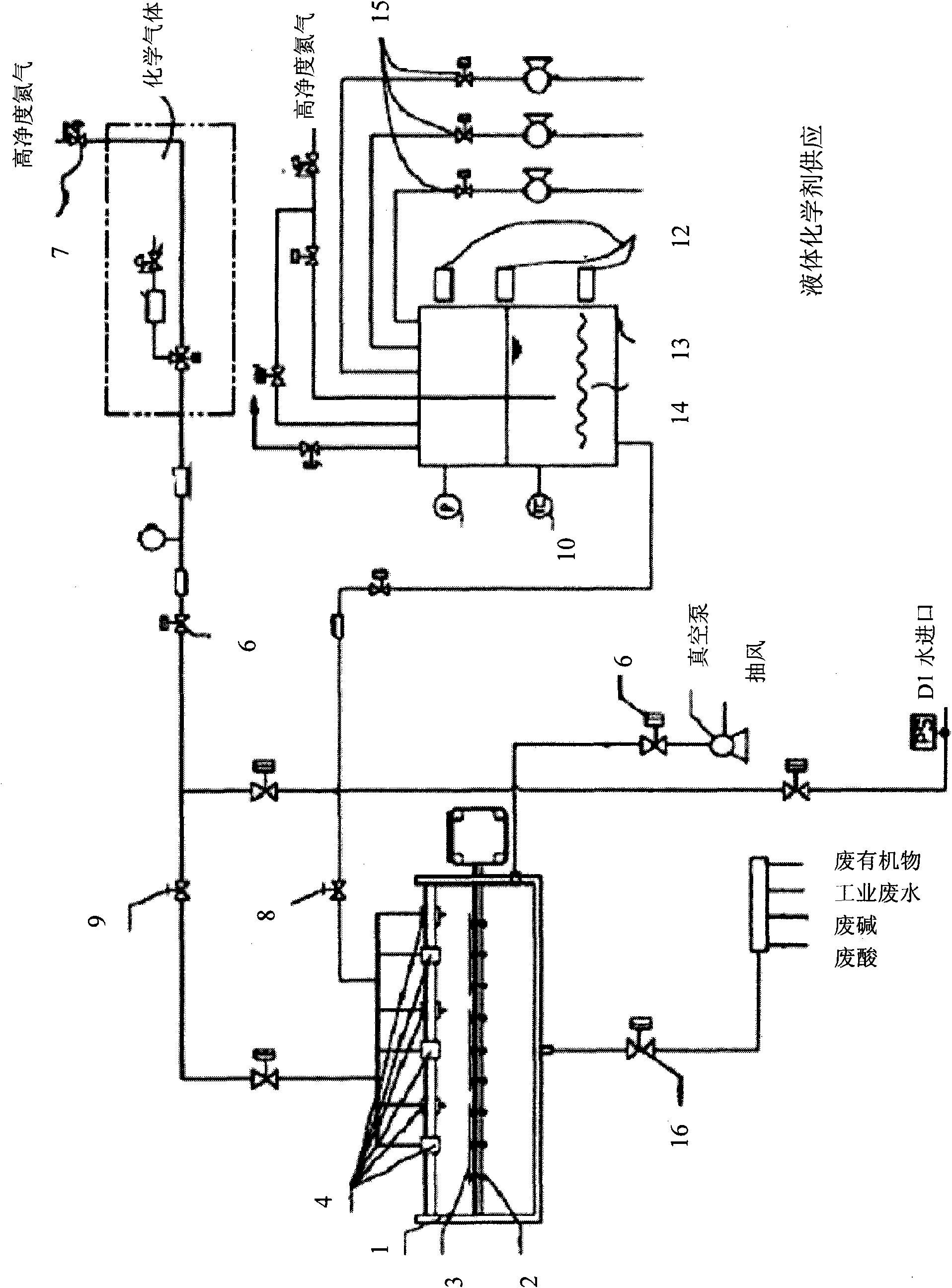

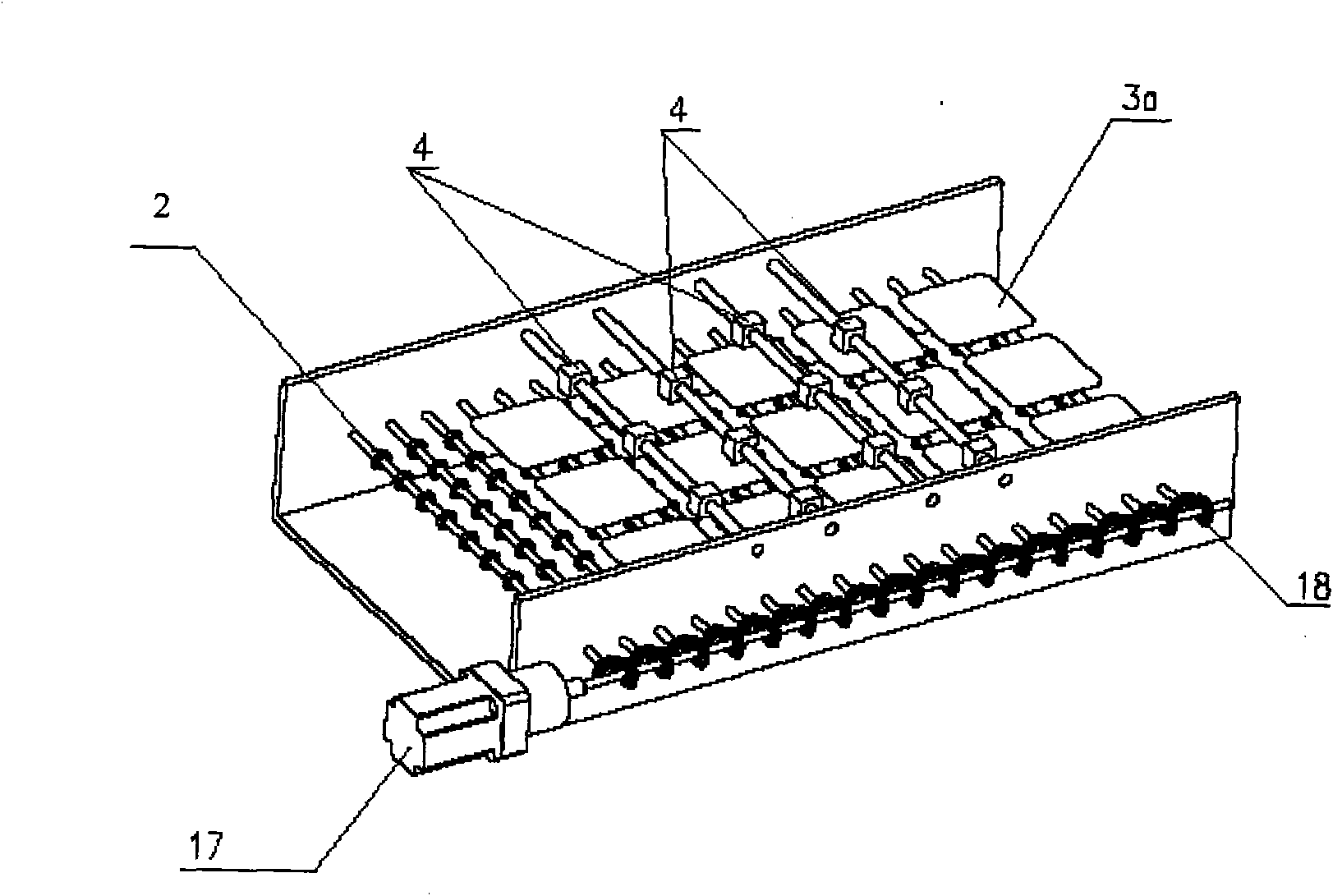

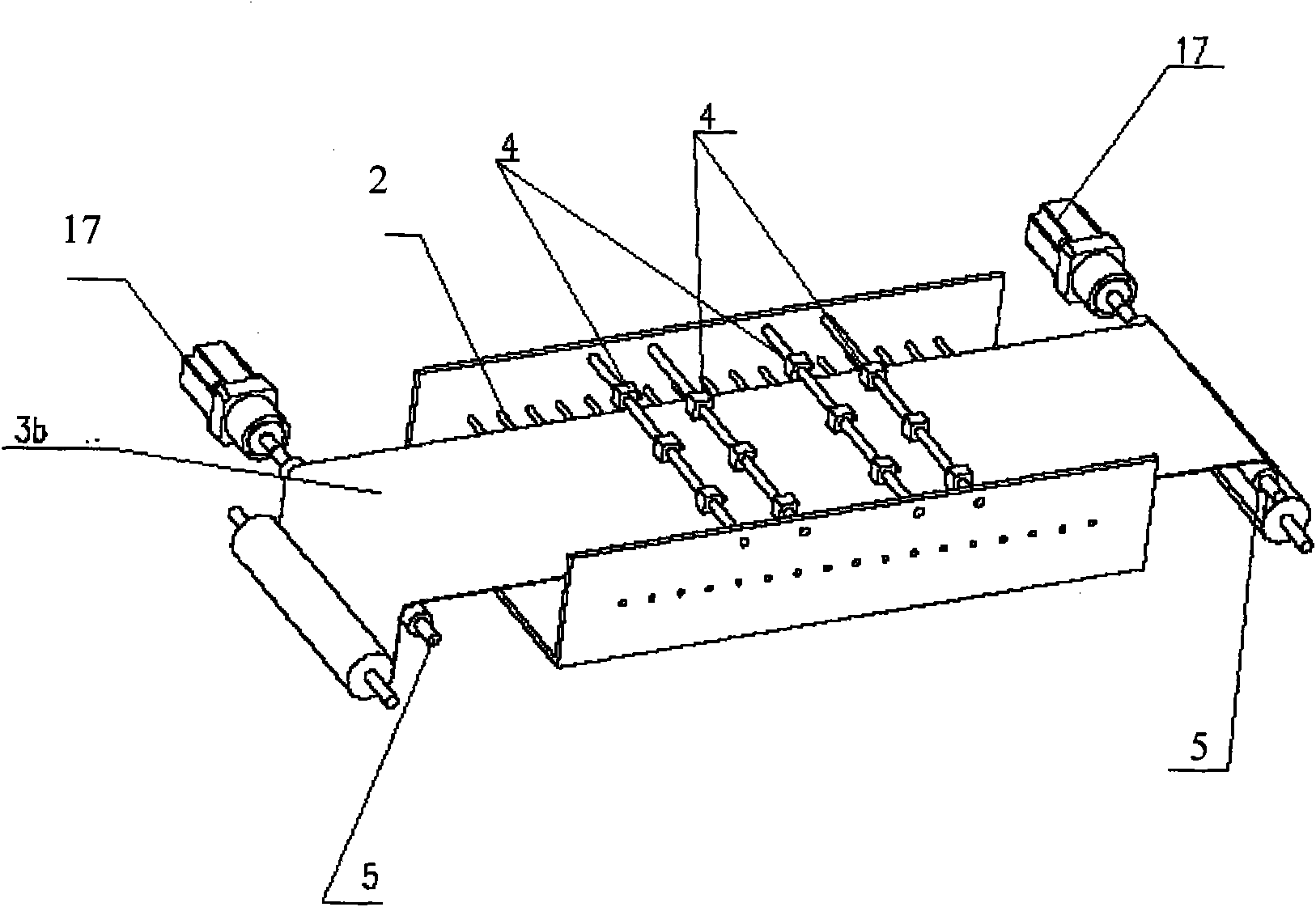

[0038] The system and method for single-sided continuous chemical wet treatment with mist chemical agent of the present invention can be used for solar cells or flat panel display substrates or thin film substrates, or components requiring chemical wet treatment in other semiconductor integrated circuits. The structural features and advantages of the chemical wet processing system and the corresponding chemical wet processing method of the present invention will be described in detail below by taking substrates and film substrates as examples.

[0039] A system and method for single-sided continuous chemical wet processing with chemical sprays includes a transport mechanism for conveying material to be treated, an atomizer for generating chemical sprays from heated gaseous chemicals and liquid chemicals, a number of Chemical wet treatment chamber unit, several deionized water spray (ultrasound / megasonic energy can be added) wet treatment process chamber unit, isopropanol (IPA) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com