Production method of abrasion-proof decorating paper

A production method and technology for decorative paper, applied in special paper, papermaking, paper and other directions, can solve the problem that the effect of the surface wear resistance of the composite floor is not very obvious, the wear resistance of the impregnated decorative paper is uneven, and the aluminum oxide powder is distributed. Non-uniformity and other problems, to achieve significant social and environmental protection effects and economic benefits, high surface overall wear resistance, uniform and stable performance, and obvious energy saving and emission reduction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

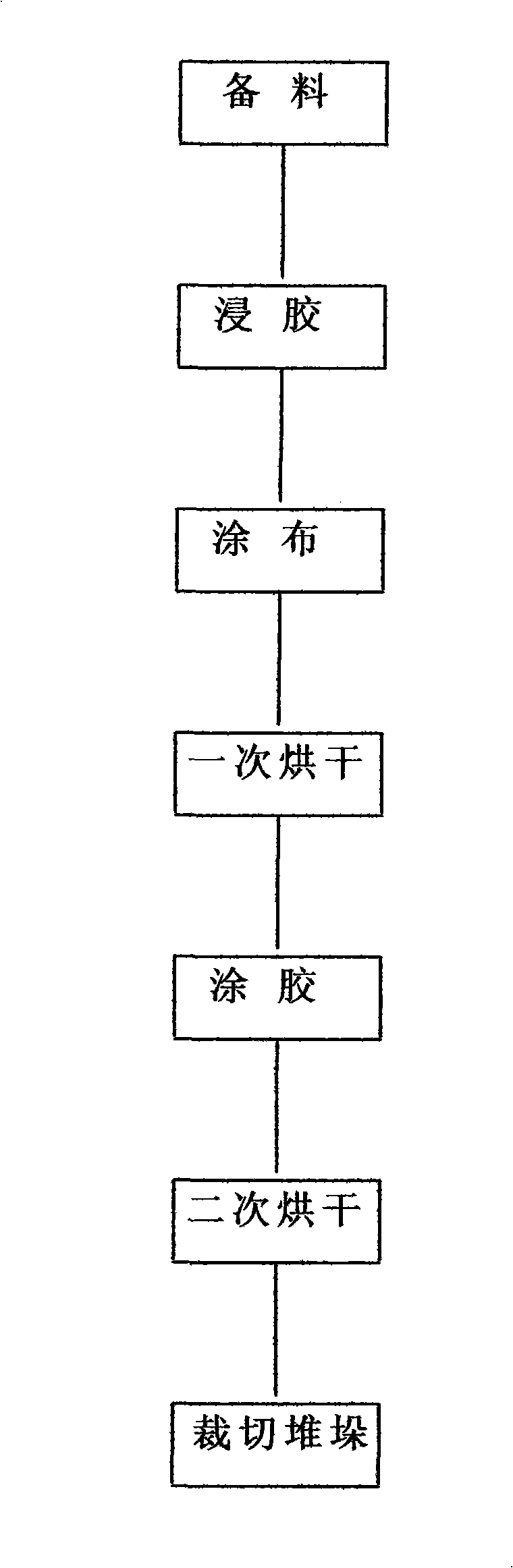

Image

Examples

Embodiment 1

[0038] A kind of production method of wear-resistant decorative paper, it carries out according to the following steps:

[0039] (1) Material preparation: Prepare decorative paper raw materials, said decorative paper raw materials are printed with decorative patterns and color patterns on the surface according to the design requirements, and the quantitative specification is 80g / m 2 wood pulp web.

[0040] (2) Dipping: weigh raw materials according to the following weight ratio:

[0041] Urine formaldehyde resin 100 parts,

[0042] Contains 12% NH 4 10 parts of aqueous solution of Cl,

[0043] The above-mentioned urea-formaldehyde resin is the commercially available UF glue chemical material. Put the above-mentioned raw materials weighed into the container and stir evenly to prepare impregnated glue. Put the prepared impregnated glue into the impregnated glue tank, and then put the printed The wood pulp roll paper with patterns and color patterns is placed on the paper she...

Embodiment 2

[0063] A kind of production method of wear-resistant decorative paper, it is on the basis of the embodiment described in embodiment one, controls the gluing amount of dipping glue to be 60g / m in the dipping step 2 , the dipping glue used is made by weighing the raw materials according to the following weight ratio and putting them into the container and stirring them evenly:

[0064] Urine formaldehyde resin 100 parts,

[0065] Contains 15% NH 4 6 parts of aqueous Cl solution.

Embodiment 3

[0067] A kind of production method of wear-resistant decorative paper, it is on the basis of the embodiment described in embodiment one, controls the gluing amount of dipping glue to be 40g / m in the dipping step 2 , the dipping glue used is made by weighing the raw materials according to the following weight ratio and putting them into the container and stirring them evenly:

[0068] Urine formaldehyde resin 100 parts,

[0069] Contains 10% NH 4 15 parts of aqueous solution of Cl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com