Method and apparatus for the application of plastics coatings

A coating and coating technology, which is applied to the device, coating, paper coating and other directions of coating liquid on the surface, can solve the problems of undesired substrate, difficult integration, and inability to apply varnish layer, etc., to improve the smoothing effect, The effect of shortening the moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

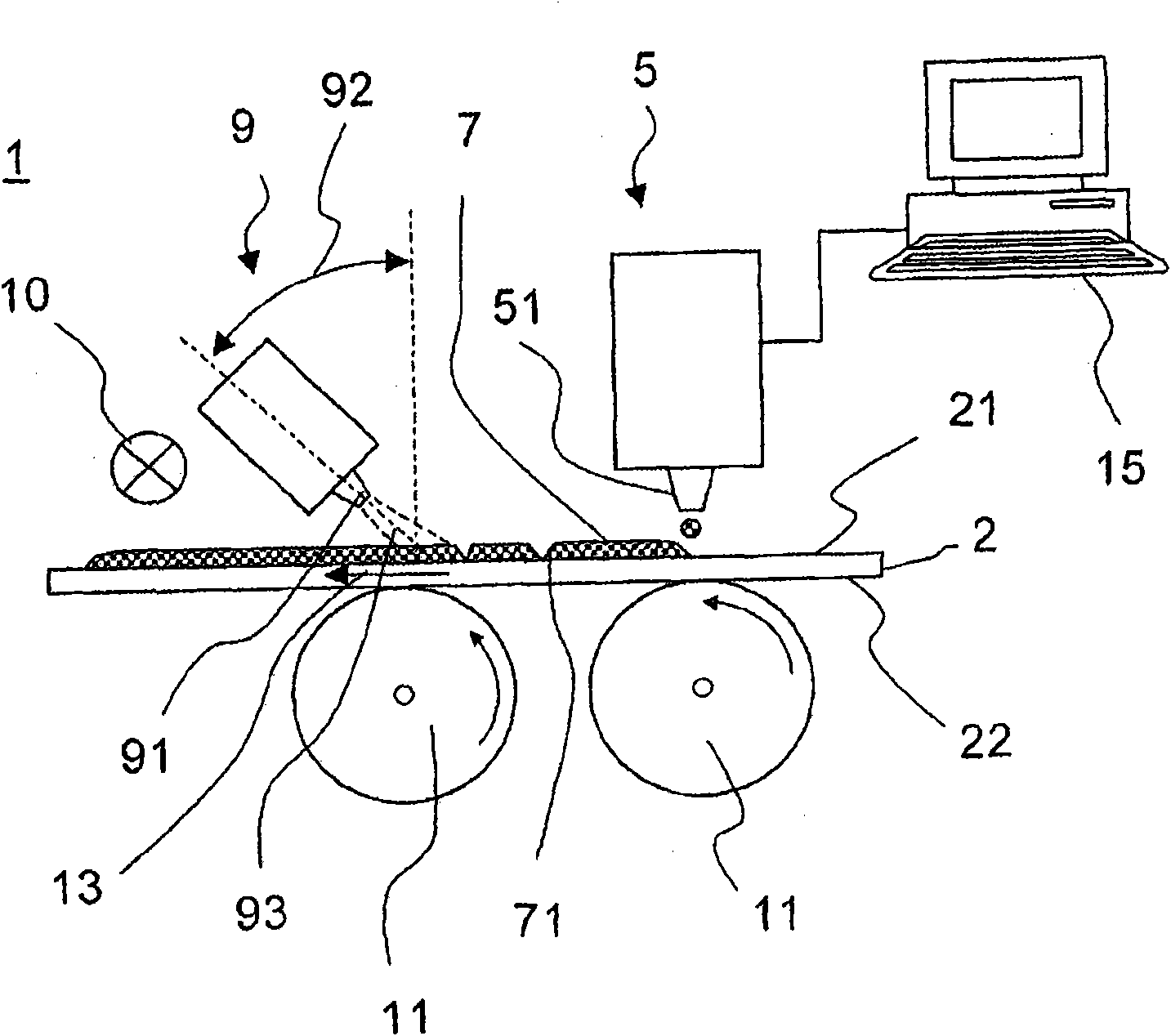

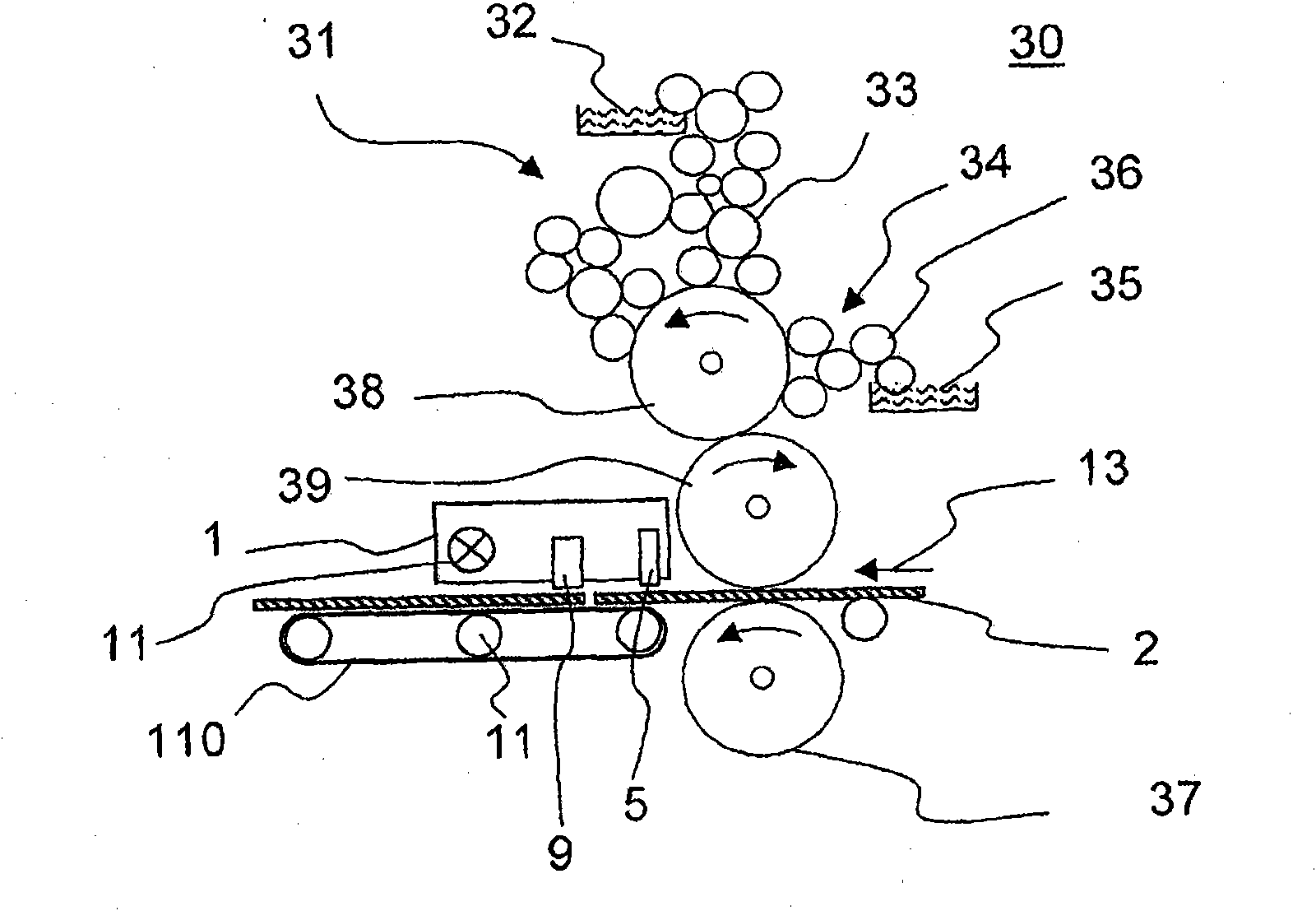

[0066] figure 1 An embodiment of a device 1 for coating finishing of printed materials is shown in FIG.

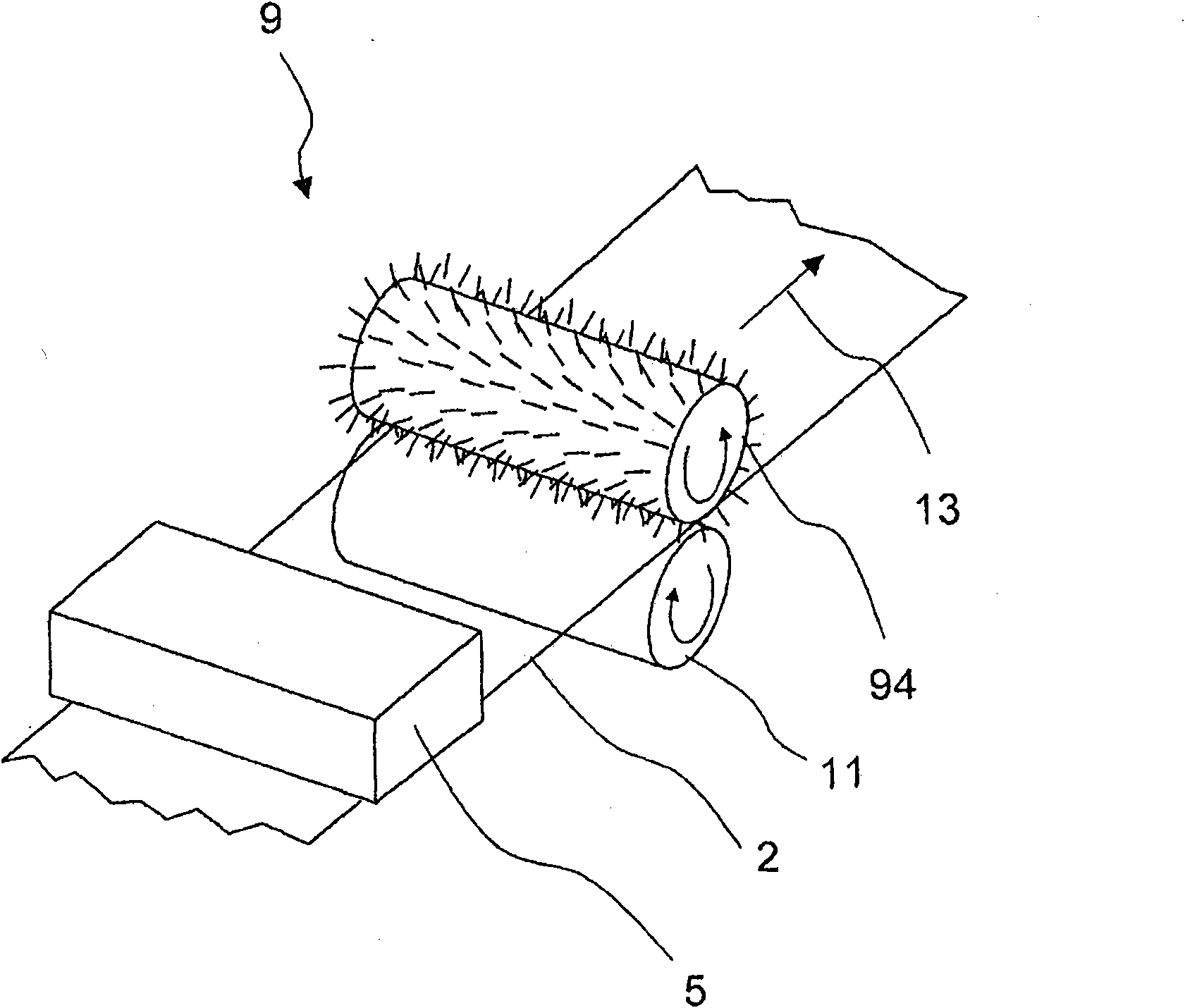

[0067] To this end, a varnish coating is applied by means of the device 1 to the surface 21 of the preferably printed paper or cardboard substrate 2 . For this purpose a transfer device is provided, which in the example shown comprises a roller 11 over which the substrate 2 is moved in the direction of movement 13 , touching at the side 22 , past the coating unit 5 in the form of a painting assembly. The coating unit 5 is controlled by a computer 15 and applies the film 7 of the initially still fluid coating material in the form of a UV-curable coating.

[0068]The coating unit 5 works according to the drop-on-demand principle, wherein the nozzles 51 of the coating unit 5 spray individual droplets onto the substrate surface 21 to be coated in response to a control signal from the computer 15, these droplets forming A continuous film is preferred. The nozzles 51 are arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com