Manufacturing method of impregnated bond paper for low formaldehyde furniture

A technology of impregnated adhesive film paper and its production method, which is applied in the direction of paper, papermaking, special paper, etc., can solve the problems of low quality, reduced formaldehyde content, and high quality impregnated adhesive film paper, so as to increase sealing performance and increase crosslinking density , the effect of reducing formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Embodiment: a kind of manufacture method of impregnated adhesive film paper for low-formaldehyde furniture, comprises the following steps:

[0043] 1) Selection and processing of base paper: choose ordinary base paper or printing paper;

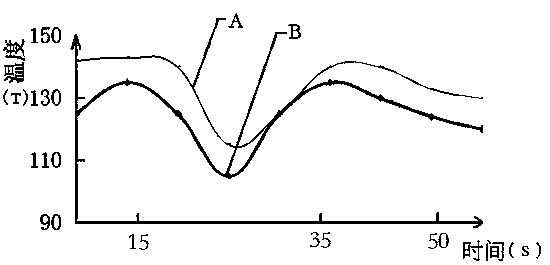

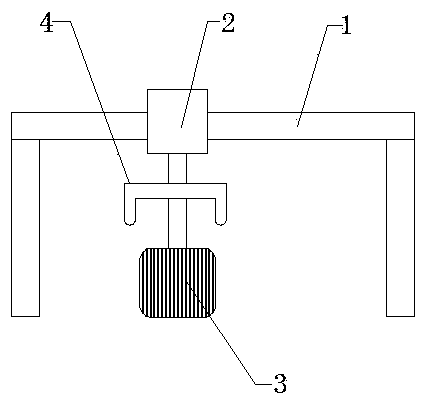

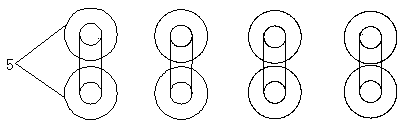

[0044]2) Uncoiling: pre-treat ordinary base paper or printing paper by smoothing and deburring; the printing paper or ordinary paper is transported from the base paper warehouse and put into a dual-axis uncoiler with a damping device that can provide the required tension for the paper. Here In the uncoiler, after a roll of paper is used up, the new paper roll can be glued to the end of the previous roll of paper without stopping the production line to realize continuous work; the deburring pretreatment refers to the process of unwinding. First use a deburring device to deburr its surface, set a support 1 above the biaxial uncoiler, set a sliding fine brush 3 for deburring on the support 1, and the upper end of the fine brush 3 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com