Preparation and application of noble metal atom cluster catalyst for acetylene hydrochlorination

A noble metal, atomic cluster technology, applied in metal/metal oxide/metal hydroxide catalyst, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc. problem, to achieve uniform size, prevent agglomeration, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

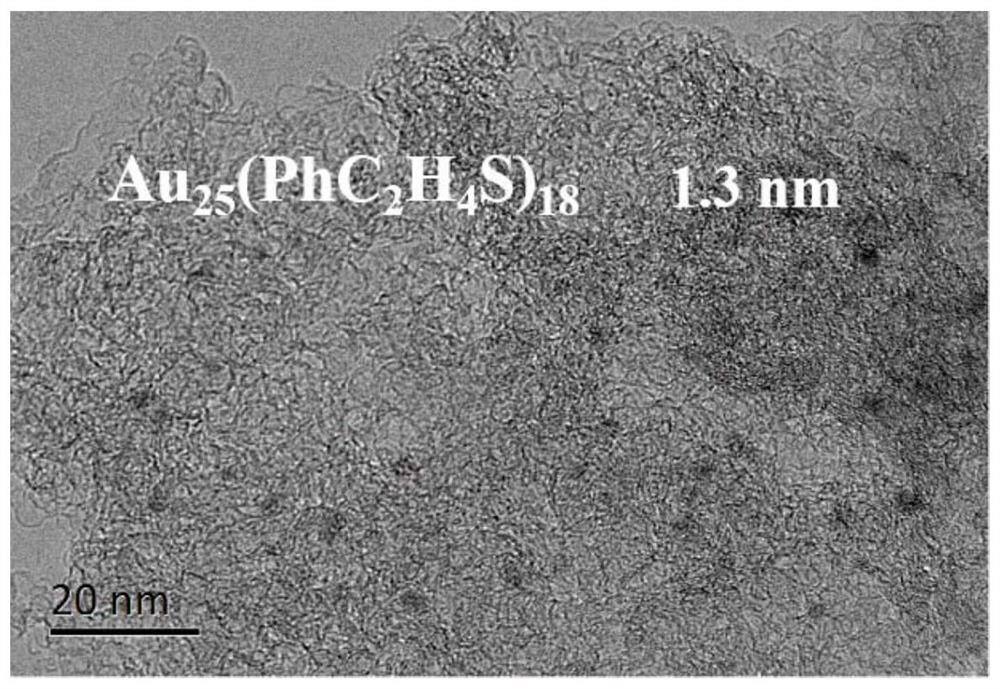

[0033] Au 25 (PhC 2 h 4 S) 18 Preparation of / AC catalyst

[0034] Weigh 60 mg of HAuCl 4 4H 2 O was added to a 50mL three-necked flask, and 15mL THF was added, and the solution was golden yellow. Add TOAB 92mg (TOAB: HAuCl 4 4H 2 O=1.16mol:1mol), the solution gradually deepened from golden yellow to orange red. After stirring for 30min, add PhCH 2 CH 2 SH 97μL (PhCH 2 CH 2 SH: HAuCl 4 4H 2 O=5mol:1mol), stirred at 25°C for one hour, added NaBH 4 (4mL ice water) 55mg (NaBH 4 : HAuCl 4 4H 2 O=10mol:1mol). Stir for three hours to stop the reaction. Wash the product with n-hexane and methanol, dissolve the precipitate with dichloromethane, remove insoluble matter, and obtain Au after drying 25 (PhC 2 h 4 S) 18 .

[0035] Activated carbon treated with hydrochloric acid was dispersed with dichloromethane, and Au dissolved in dichloromethane was added dropwise. 25 (PhC 2 h 4 S) 18, stirred overnight at 25°C, and dried by centrifugation to obtain Au 25 / A...

Embodiment 2

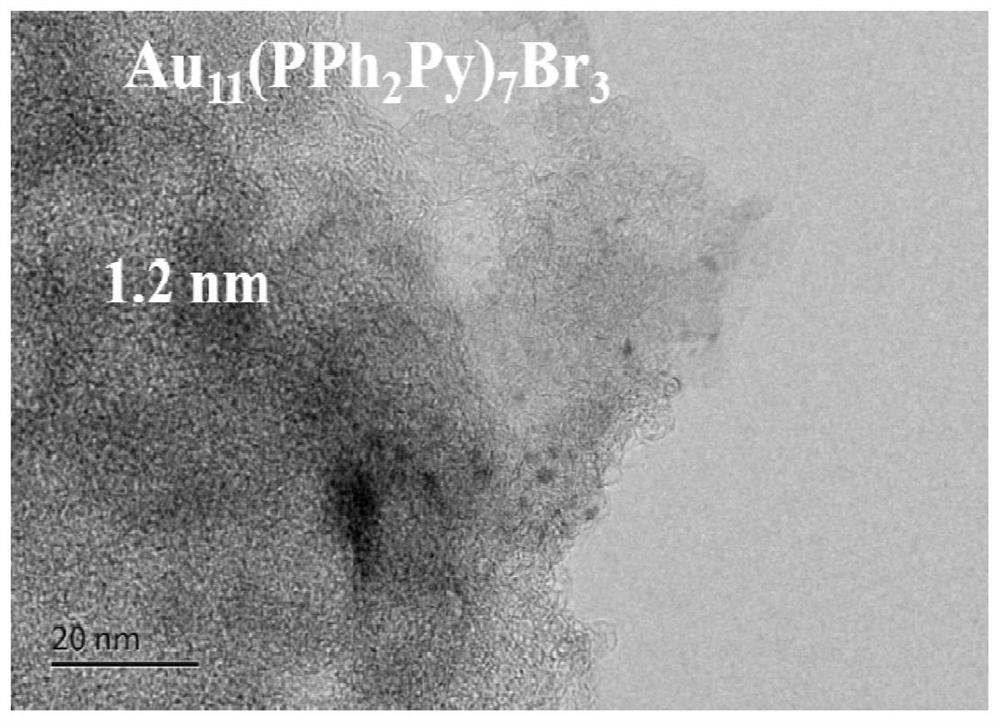

[0038] Au 11 (PPh 2 Py) 7 Br 3 Preparation of / AC catalyst

[0039] Weigh 240mgHAuCl 4 and 306mgPPh 2 Py, add 0.0105mL H 2 O, the solvent is ethanol, after stirring at 25°C for 9.5h, washing with ethanol and drying to obtain Au I (PPh 2 Py)Cl. Weigh 40mg [Au I (PPh 2 Py)Cl] and 85 mg tetra-n-octylammonium bromide (TOAB: HAuCl 4 4H 2 O=1.16mol: 1mol) was dissolved in 10mL ethanol and stirred in a round bottom flask (600rpm / min), then NaBH 4 (15.2 mg, NaBH 4 : HAuCl 4 4H 2 O=5mol:1mol) was dissolved in 1mL of ethanol, and slowly added dropwise. After reacting for 12 h, the mixture was poured into 10 mL of water, centrifuged by a centrifuge at 4000 rpm to obtain a black solid, which was washed several times with n-hexane / dichloromethane (v / v=5 / 1) to remove excess PPh 2 Py ligand and TOAB. Finally, the precipitate obtained above was extracted with 2 mL of methanol, centrifuged again (10,000 rpm, 5 min) to remove insoluble matter, and the obtained solution was dri...

Embodiment 3

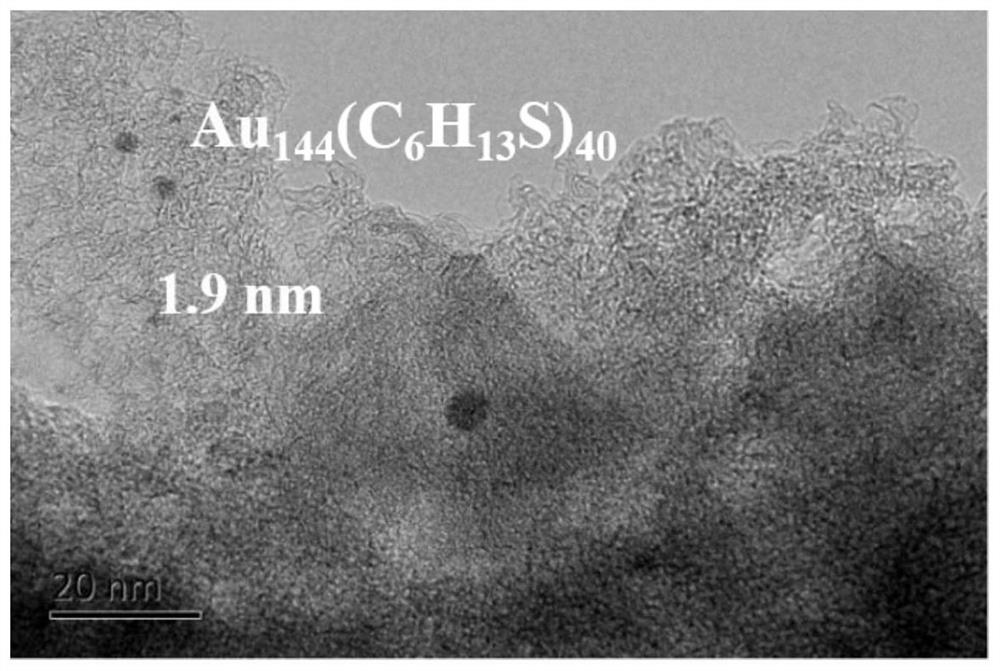

[0043] Au 144 (C 6 h 13 S) 60 Preparation of / AC catalyst

[0044] Weigh 60 mg of HAuCl 4 4H 2 O was added to a 50mL three-necked flask, and 15mL of methanol was added, and the solution was golden yellow. Add TOAB 92mg (TOAB: HAuCl 4 4H 2 O=1.16mol:1mol), the solution gradually deepened from golden yellow to orange red. After stirring for 30 min, add C 6 h 13 SH 87μL (C 6 h 13 SH: HAuCl 4 4H 2 O=5mol:1mol), stirred at room temperature at 25°C for one hour, added NaBH 4 (4mL ice water) 55mg (NaBH 4 : HAuCl 4 4H 2 O=10mol:1mol). Stir at 25°C for five hours to stop the reaction. Wash the product with methanol, wash with acetone, dissolve the precipitate with dichloromethane, remove insoluble matter, and obtain Au after drying 144 (C 6 h 13 S) 60 .

[0045] Activated carbon treated with hydrochloric acid was dispersed with dichloromethane, and Au dissolved in dichloromethane was added dropwise. 144 (C 6 h 13 S) 60 , stirred overnight at 25°C, and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com