Electrolysis circulating flue gas desulfurization method utilizing reclamation semidry method

A technology of circulating flue gas and semi-dry method, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of high investment and operating costs, large floor space, slow reaction speed, etc., and achieve operating costs Low, high desulfurization rate, fast reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will further illustrate the resource utilization semi-dry method-electrolytic circulation flue gas desulfurization method of the present invention in conjunction with specific examples, and the present invention is not limited to the following examples.

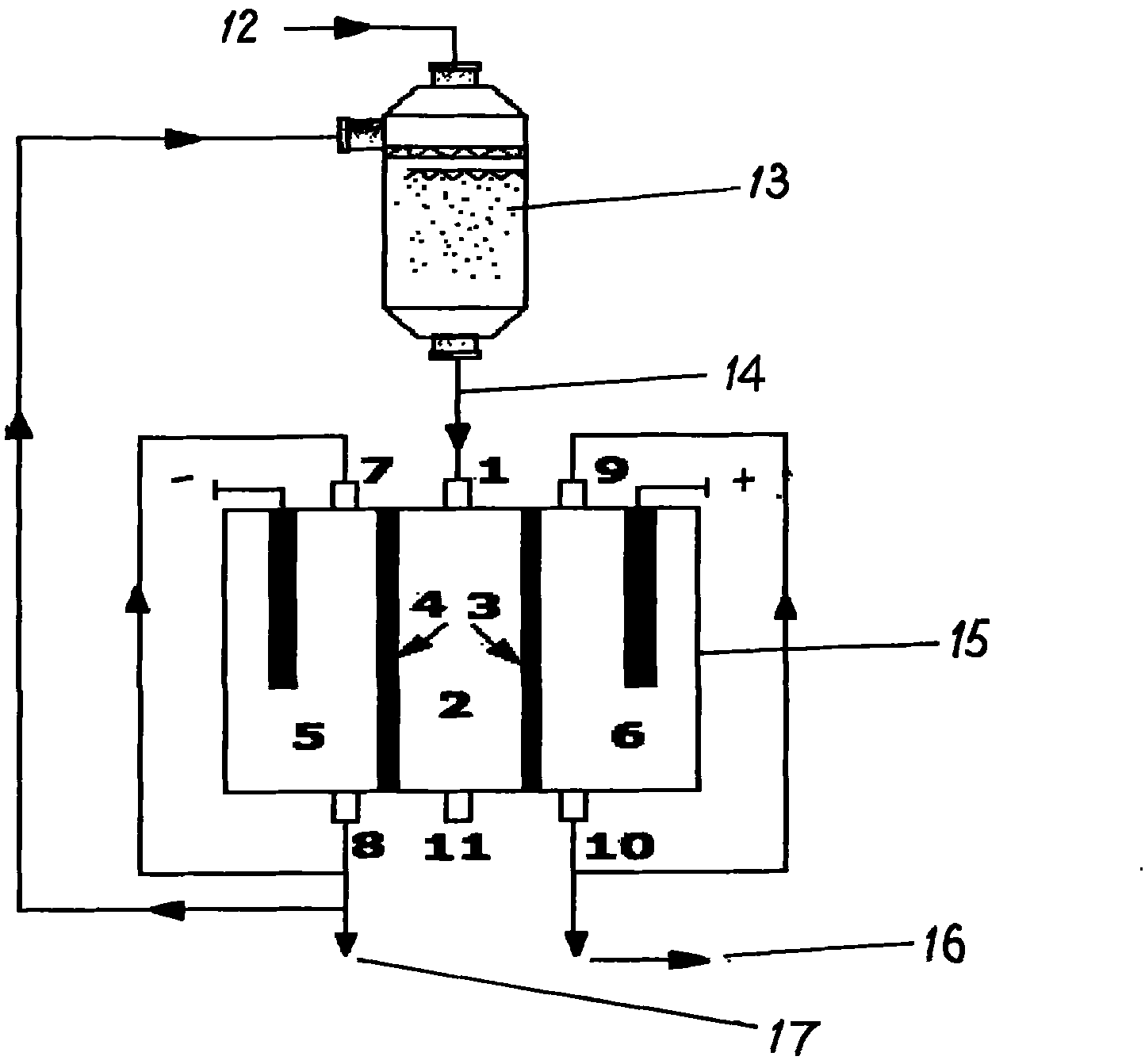

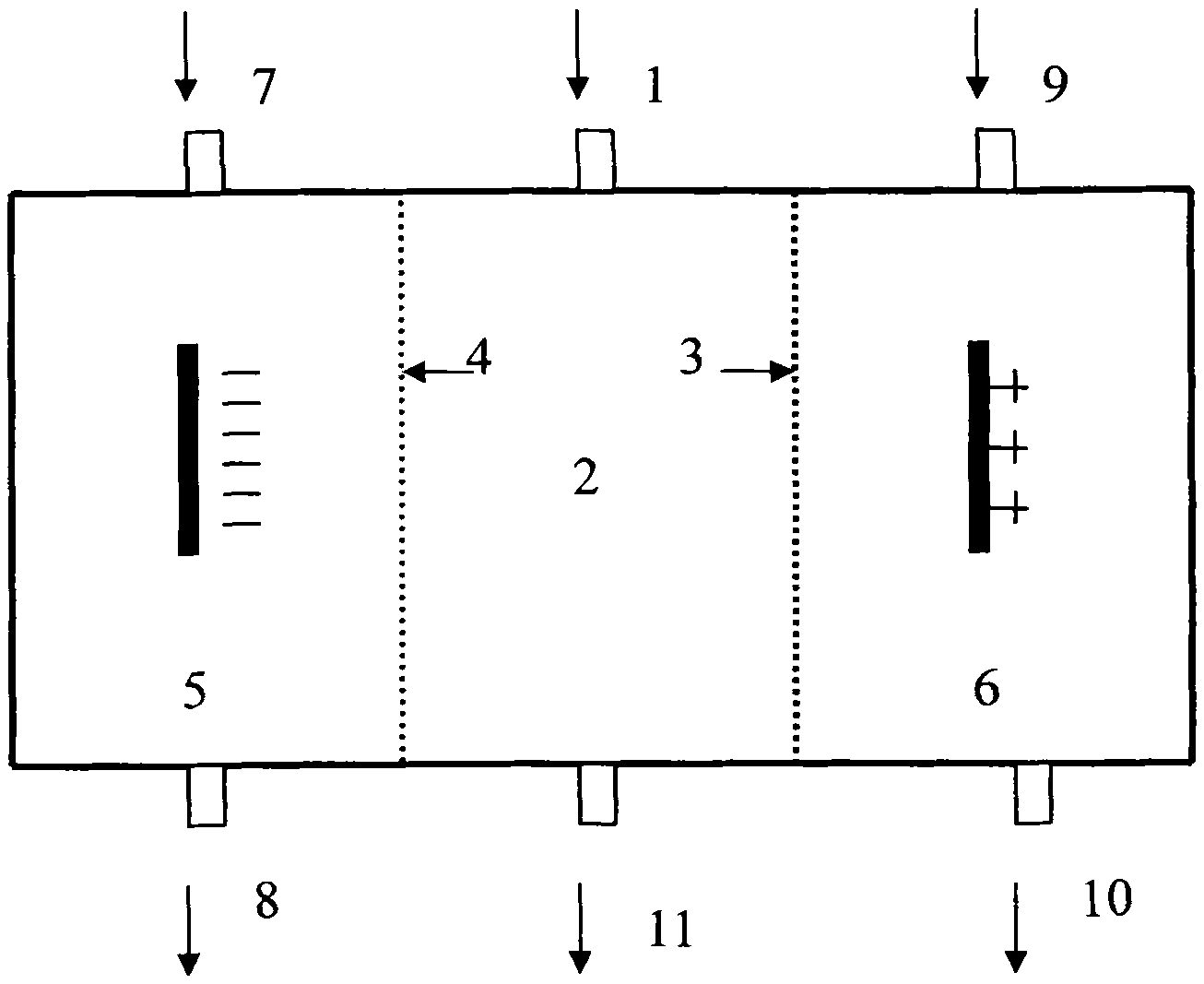

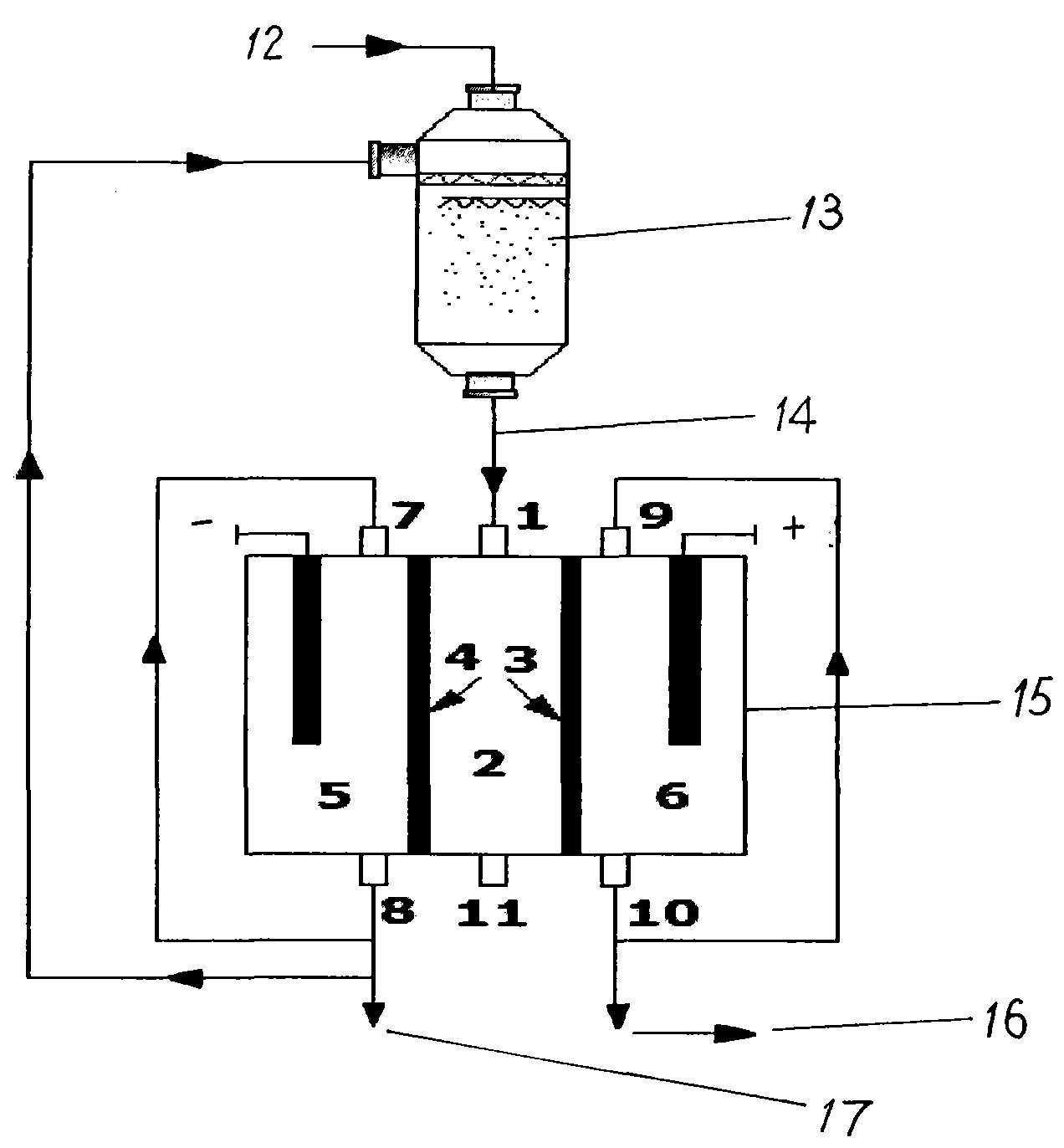

[0037] The technique of the resourceful semi-dry method-electrolytic circulation flue gas desulfurization method of the present invention mainly comprises the following contents (see attached figure 1 ):

[0038] (1) Leading the sulfur-containing flue gas 12 into the semi-dry desulfurization tower 13, using a sodium hydroxide solution with a concentration higher than 10% to perform semi-dry desulfurization of the waste gas, and obtaining sodium sulfate powder after desulfurization;

[0039] (2) Sodium sulfate powder is dissolved in soft water to prepare a sodium sulfate solution with a concentration higher than 15%, and the solution is refined to remove insoluble substances therein. The extent to which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com