Oxide-doped medium-low temperature mixed conducting oxygen-permeable membrane material and its preparation method

A technology of mixed conductors and oxides, which is applied in the field of medium and low temperature mixed conductor oxygen permeable membrane materials and their preparation, can solve problems such as affecting the oxygen flux and stability of materials, achieve high chemical and structural stability, improve stability, The effect of meeting the requirements of medium and low temperature operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

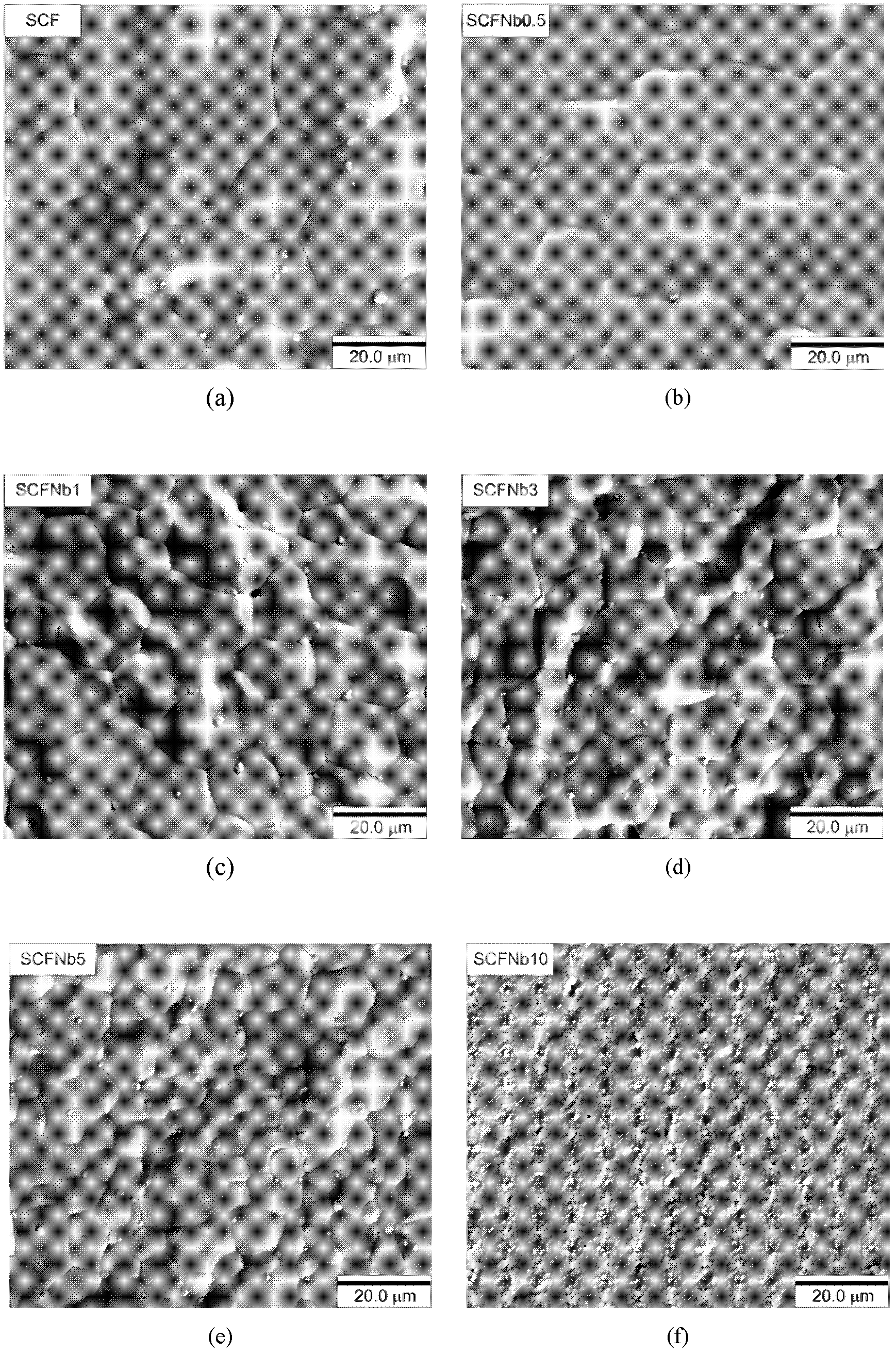

[0021] Preparation of Perovskite Oxide SrCo by Solid State Reaction Method 0.8 Fe 0.2 o 3-δ (-0.50.8 Fe 0.2 o 3-δ -Nb 2 o 5 (-0.53 、Co 2 o 3 and Fe 2 o 3 After the powders were mixed, ethanol was added, placed in a ball mill for wet grinding for 36 hours at a speed of 350 rpm, and then dried in static air. Put the dried powder in a high-alumina crucible and bake it in an air atmosphere at 900°C for 5 hours to obtain SrCo 0.8 Fe 0.2 o 3-δ (SCF) powder. Will Nb 2 o 5 0.5, 1, 3, 5, 10% of the total mass of the oxygen permeable membrane material and SrCo 0.8 Fe 0.2 o 3-δ Mix, add ethanol, and place in a ball mill for ball milling at a speed of 400 rpm for 8 hours. After ball milling, the powder is fully dried in air at 120°C. Put the dried powder in a corundum crucible and bake it in an air atmosphere at 950°C for 5 hours to obtain SrCo 0.8 Fe 0.2 o 3-δ -Nb 2 o 5 The powders are represented by SCFNb0.5, SCFNb1, SCFNb3, SCFNb5, and SCFNb10 respectively.

[0...

Embodiment 6

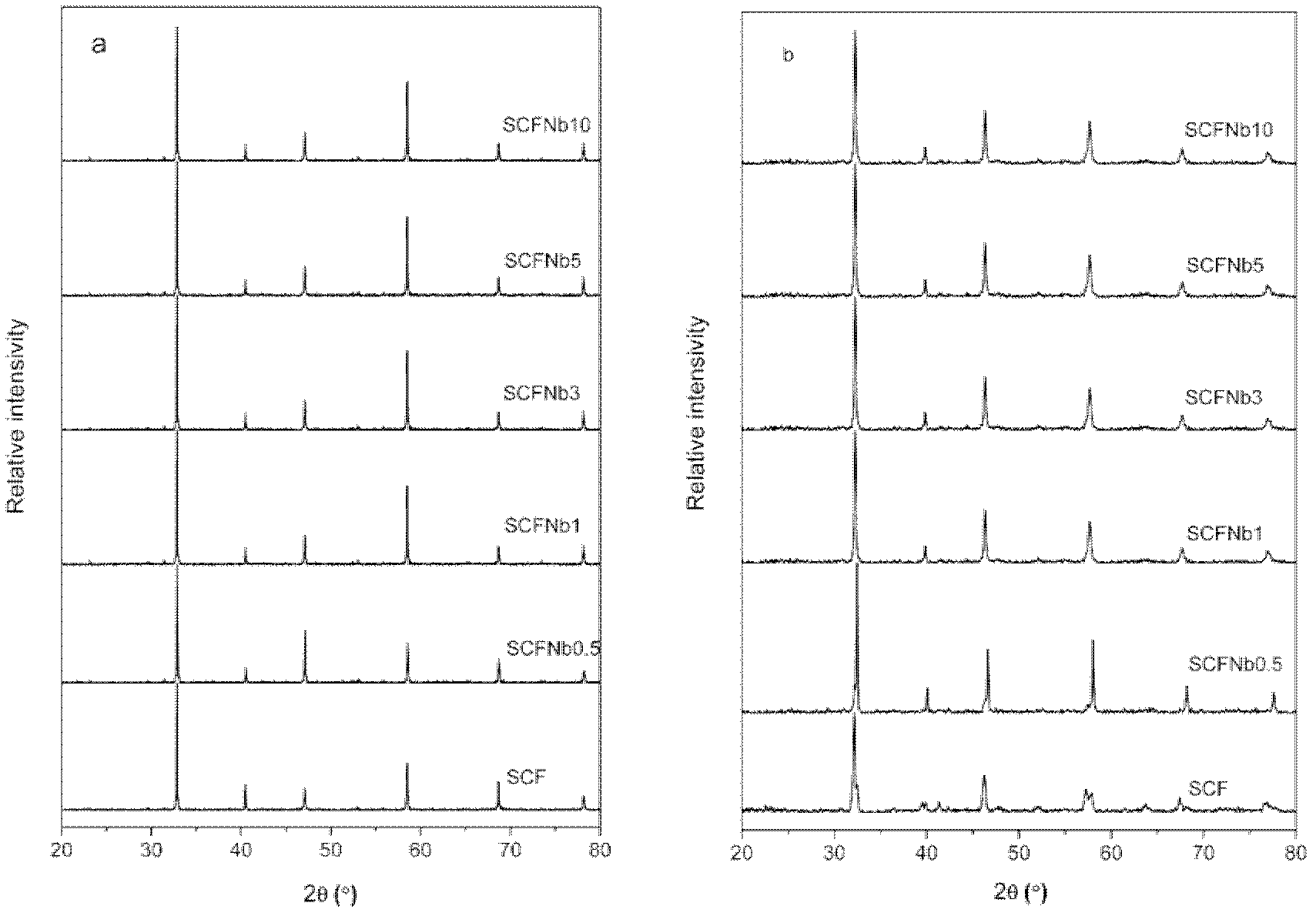

[0024] The perovskite material SrCo 0.8 Fe 0.2 o 3-δ Materials and Nb 2 o 5 Doped example 1-5 material SrCo 0.8 Fe 0.2 o 3-δ -Nb 2 o 5 X-ray diffraction tests were carried out by figure 2 (a) It can be seen that the materials SCF and SCFNb both form a complete perovskite phase, and no significant change is found in the main perovskite phase of the material before and after doping. The study found that the material has no obvious second phase or the impurity phase generated by the phase reaction is one of the prerequisites to ensure the material has a high oxygen flux. And in the material of the present invention, Nb 2 o 5 It has a high solid solution limit (greater than 10%) in the main phase of SCF, and the prepared material has no obvious impurity phase, which predicts to a certain extent that Nb 2 o 5 The effect on the oxygen flux of the host phase SCF is relatively small. figure 2 (b) is the XRD pattern of the material after being treated in He atmosphere a...

Embodiment 7

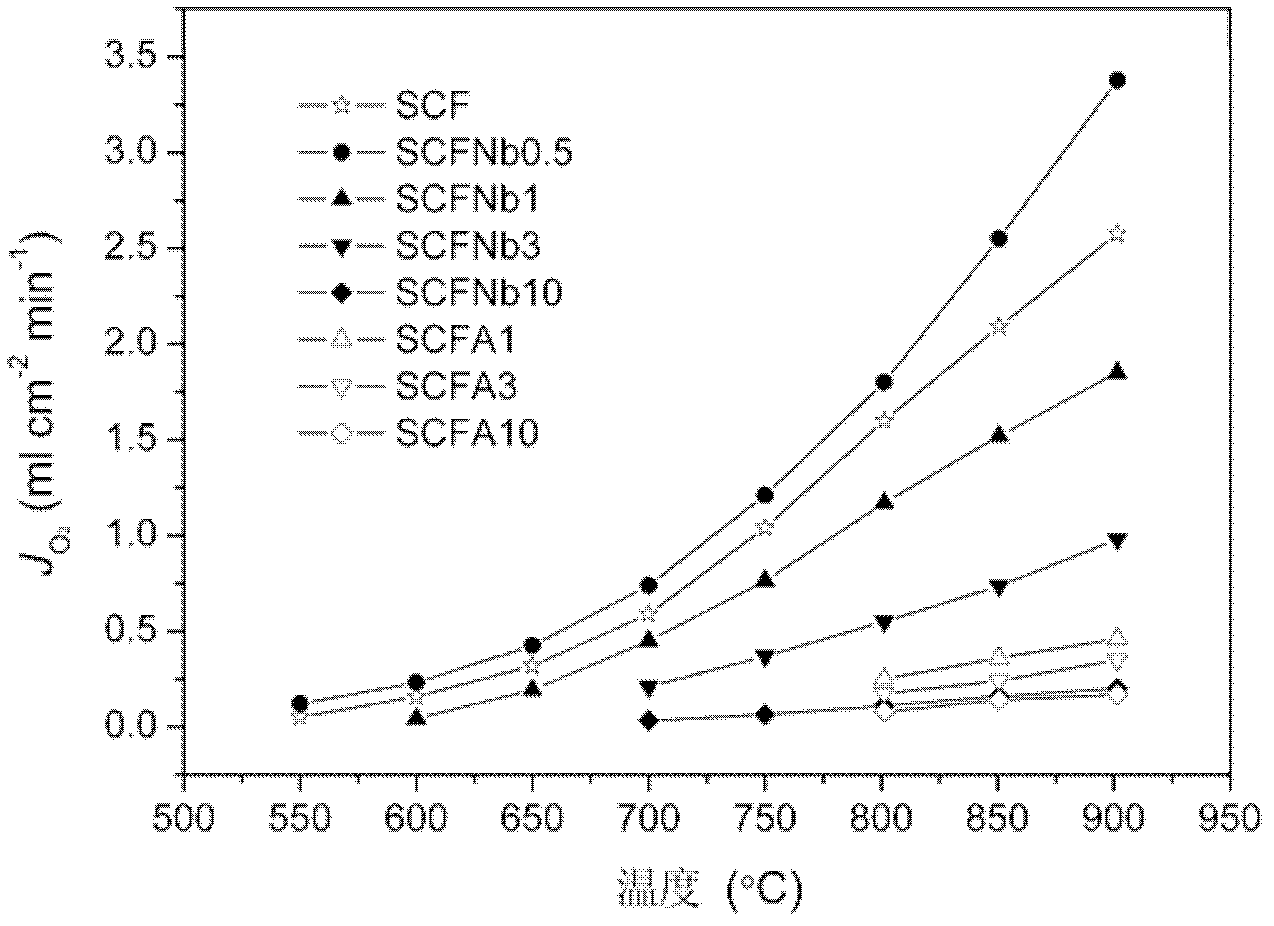

[0026] For the perovskite material SrCo 0.8 Fe 0.2 o 3-δ Materials and Nb 2 o 5 Doped (Example 1-5 doping amount is 0.5, 1, 3, 5, 10% by mass percentage) the material SrCo of the present invention 0.8 Fe 0.2 o 3-δ -Nb 2 o 5 The oxygen permeability performance at different temperatures was tested (the thickness of the membrane is 1mm, the air flow rate on the feed side is 100ml / min, and the helium flow rate on the permeation side is 30ml / min), and compared with the material SrCo reported in the literature. 0.8 Fe 0.2 o 3-δ -Al 3 o 3 For comparison (membrane thickness is 1mm, feed side air flow is 100ml / min, permeate side helium flow is 30ml / min). see results image 3 .

[0027] Depend on image 3 It can be seen that a small amount of transition metal element oxide Nb 2 o 5 (0.5%) can significantly improve the oxygen permeability of the material, and the oxygen flux of SCFNb0.5 at 900 ° C is as high as 3.37ml / (cm 2 min), suitable for applications in oxygen sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com