Patents

Literature

31results about How to "Guaranteed cracking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

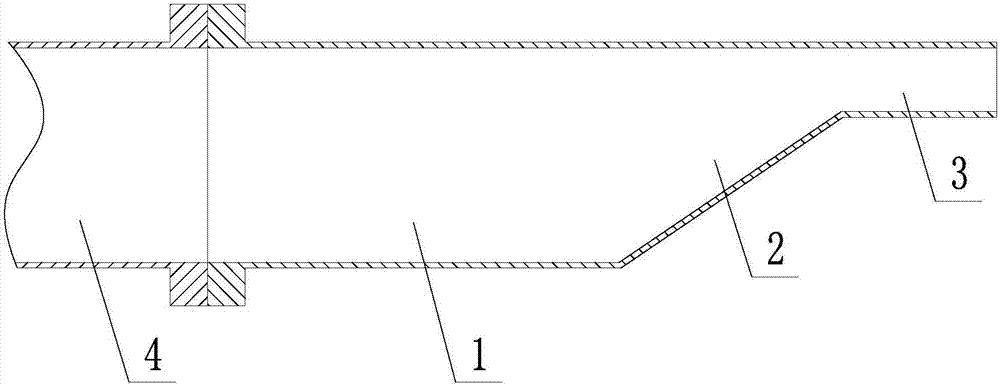

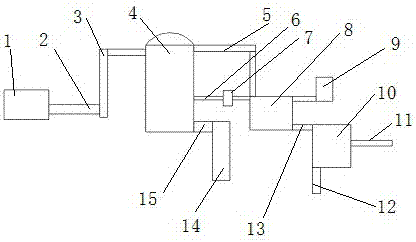

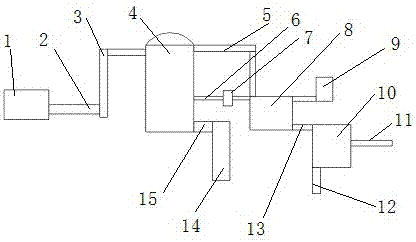

Nut cracker

The invention relates to a nut cracker which overcomes the defect of the prior art that a nut with sharp corners is easy to be split into two equal parts instead of achieving the cracking effect of cracking. The nut cracker comprises a stander, a feeding hopper, a discharging hopper as well as a roller, a driving device and a knocking hammer which are both arranged between the feeding hopper and the discharging hopper, wherein the knocking hammer is connected with the driving device through a driving arm; the end part of the knocking hammer is provided with a concave arc-shaped knocking surface; and the center of the arc-shaped knocking surface is provided with a sharp-angled sunken cavity. The sharp-angled sunken cavity cannot let a nut to be split into two equal parts, thereby ensuring the cracking effect; and concave cavities which are distributed at 180 degrees at intervals are arranged on a driving shaft and keep contact with the driving arm, thus, continuously knocking twice at the same position can be ensured to achieve reasonable cracking effect.

Owner:方向伟

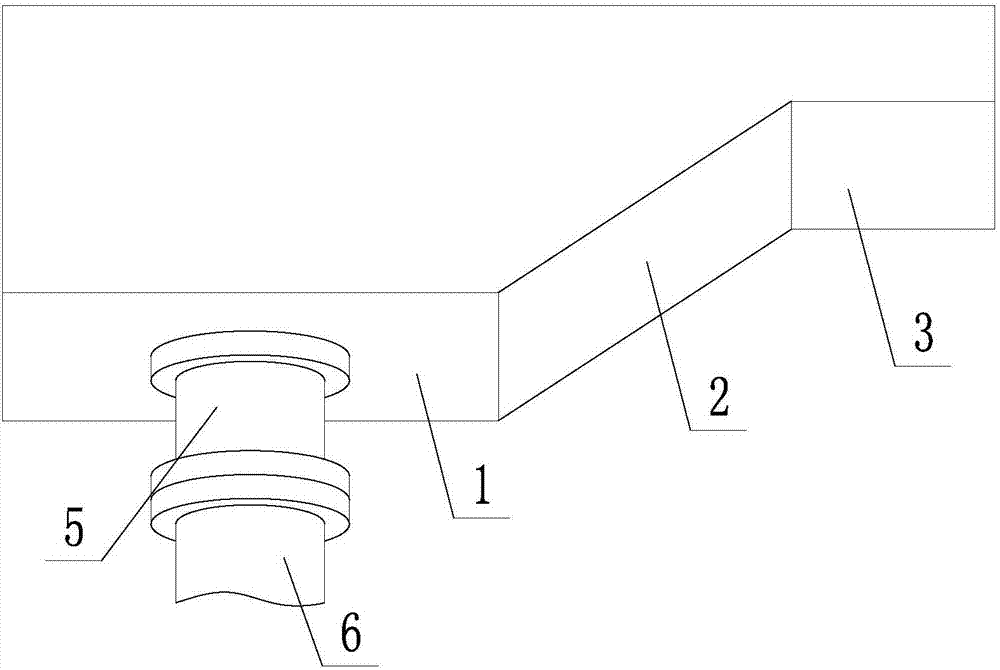

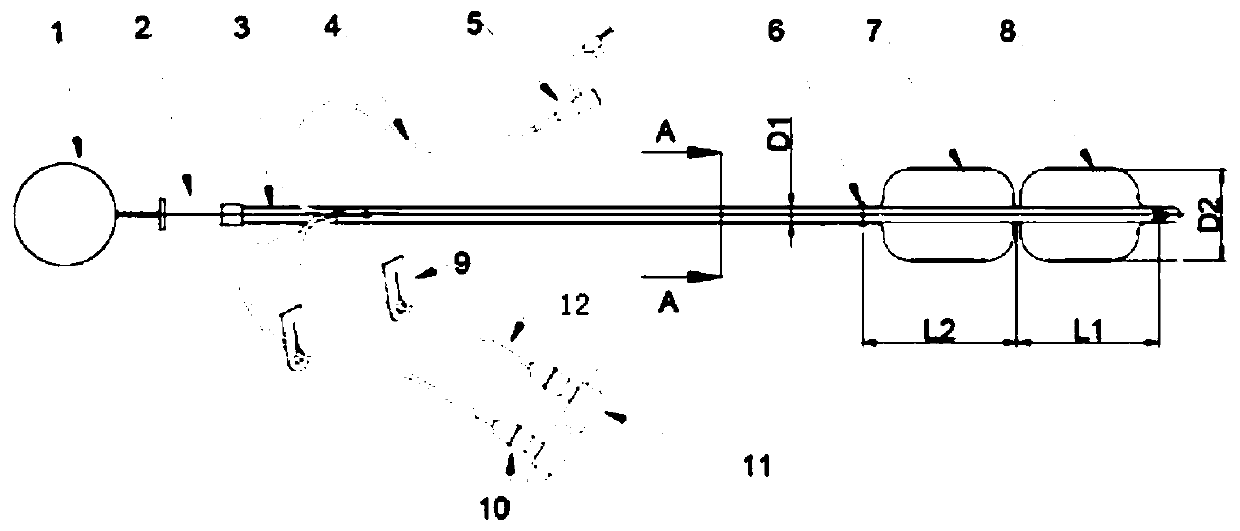

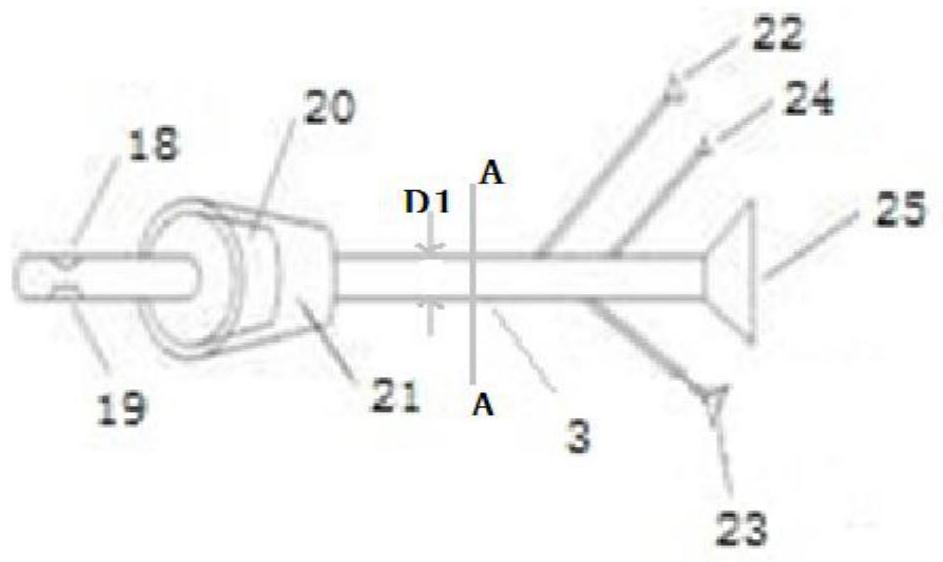

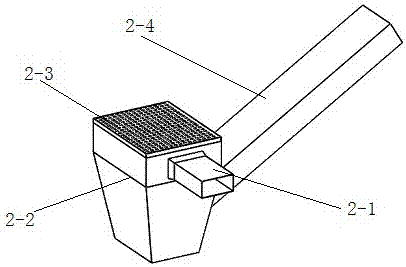

Rock surface fracturing microwave focusing radiator

InactiveCN107035316AImprove absorption efficiencyGuaranteed cracking effectDisloding machinesDrilling machines and methodsMicrowaveCoaxial cable

A rock surface fracturing microwave focusing radiator comprises a standard waveguide section, an impedance matching section and a compression radiation section. The standard waveguide section is used for allowing microwaves transmitted by a microwave source to be connected and is connected with the compression radiation section through the impedance matching section which forms impedance matching between the standard waveguide section and the compression radiation section. The compression radiation section radiates the focused microwaves outwards. The standard waveguide section and the compression radiation section both adopt uniform section rectangular metal cavities, and the impedance matching section adopts a variable section rectangular metal cavity. The wide edge sizes of the standard waveguide section, the impedance matching section and the compression radiation section are matched with the wave length of the microwaves transmitted by the microwave source. The longitudinal narrow edge size of the impedance matching section is in linear transition from large to small. The large size end of the impedance matching section is connected with the standard waveguide section, and the small size end of the impedance matching section is connected with the compression radiation section. The standard waveguide section has two microwave connection structure forms, the first microwave connection structure form is that the microwaves are connected through a rectangular waveguide or annular device, and the second microwave connection structure form is that the microwaves are connected through a coaxial converter and a coaxial cable.

Owner:NORTHEASTERN UNIV

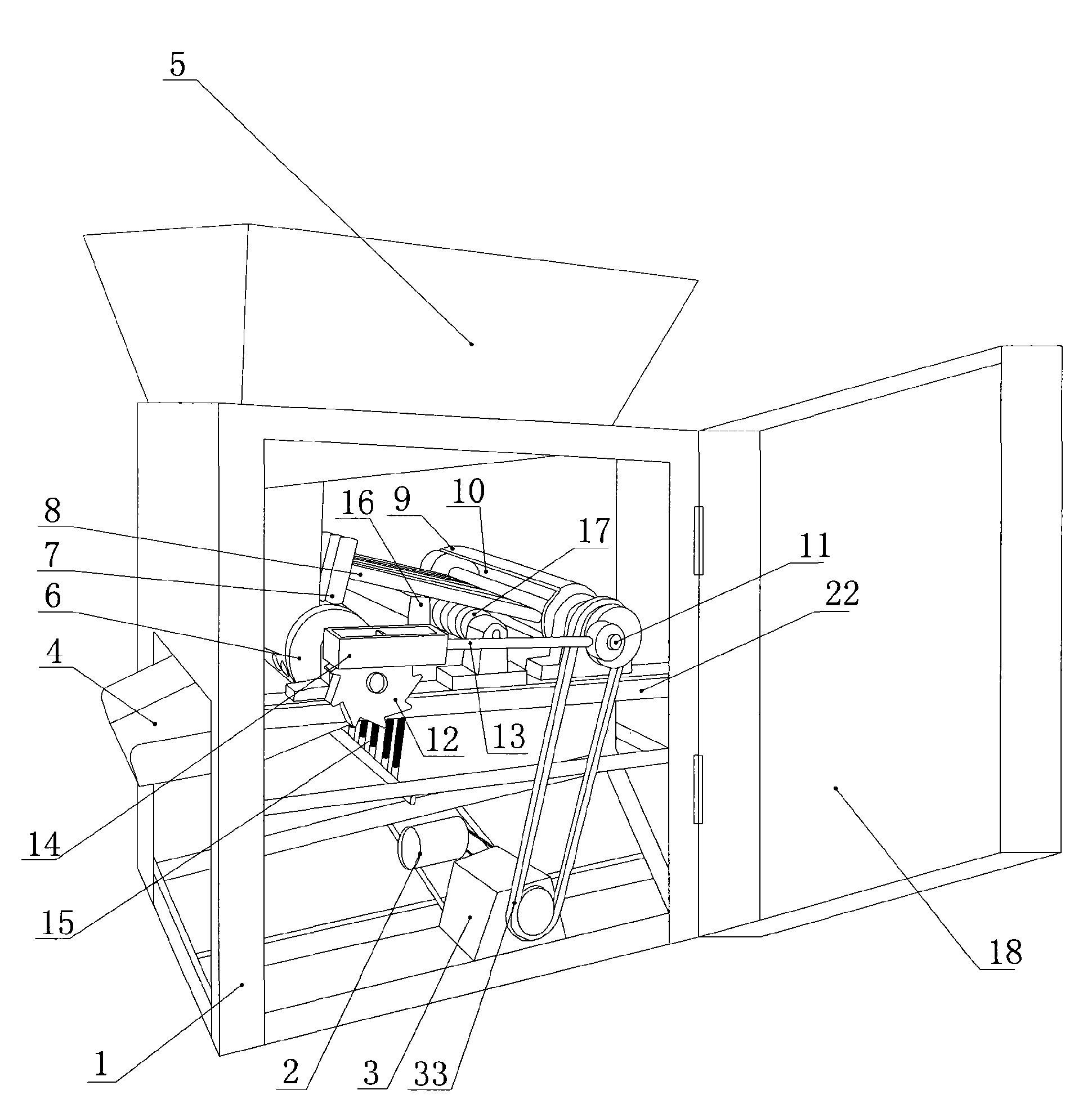

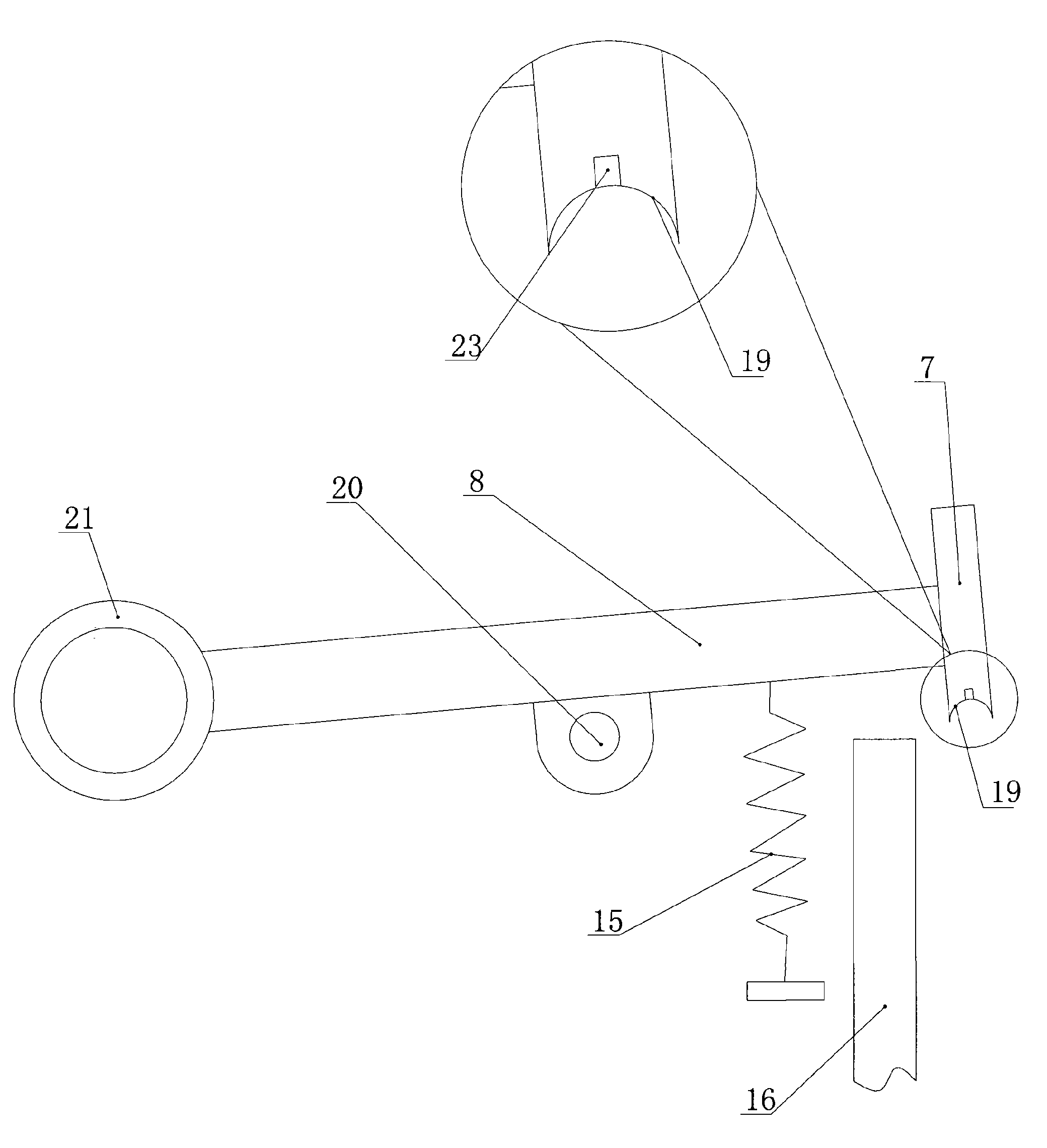

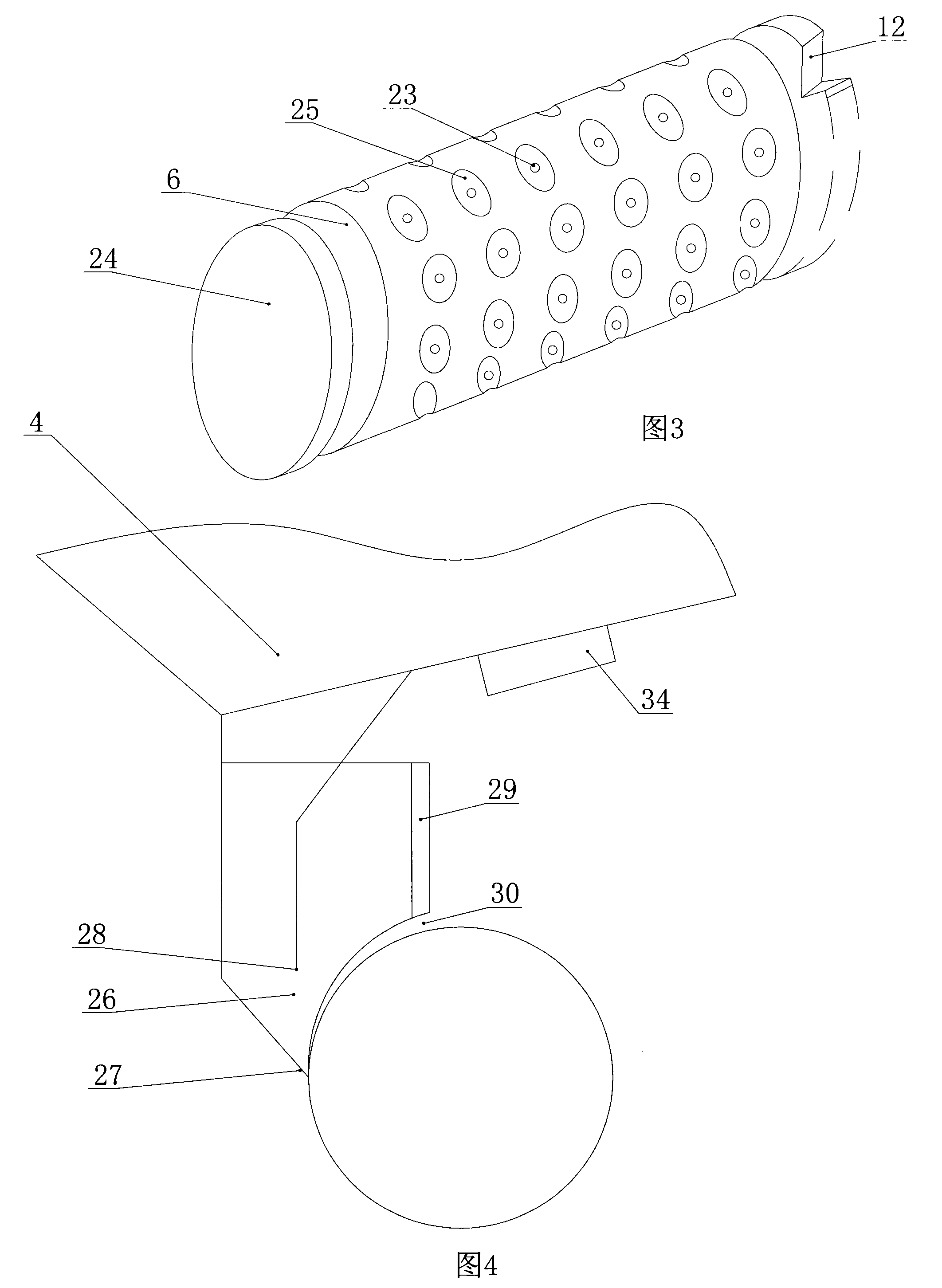

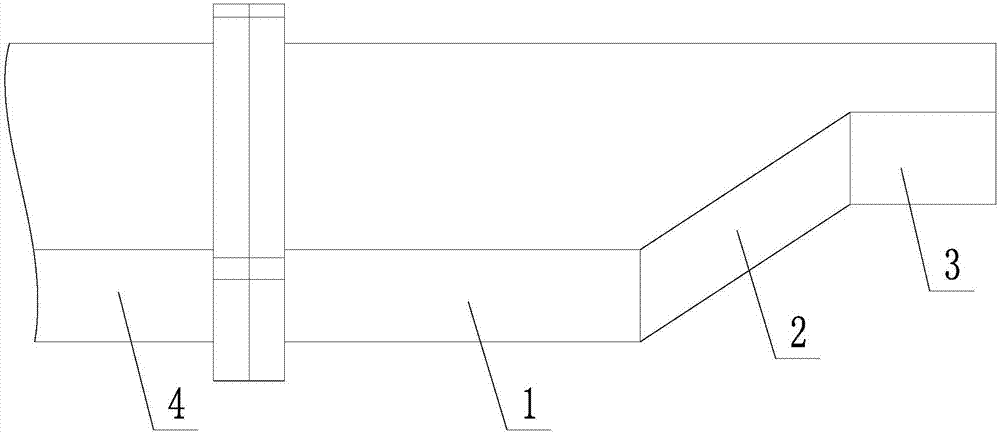

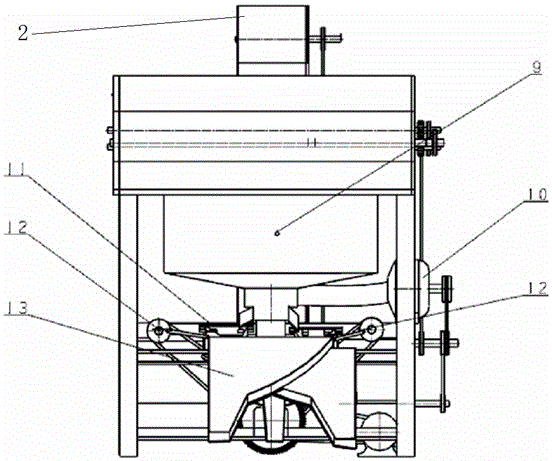

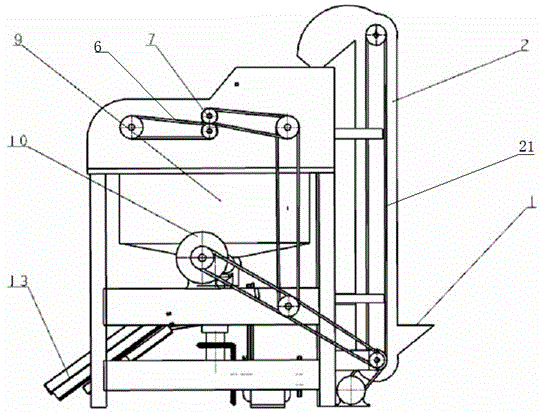

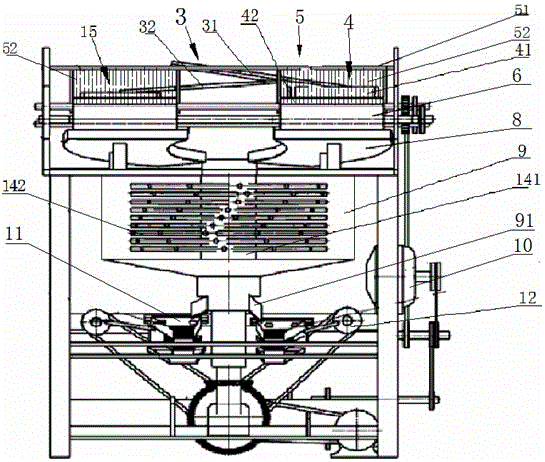

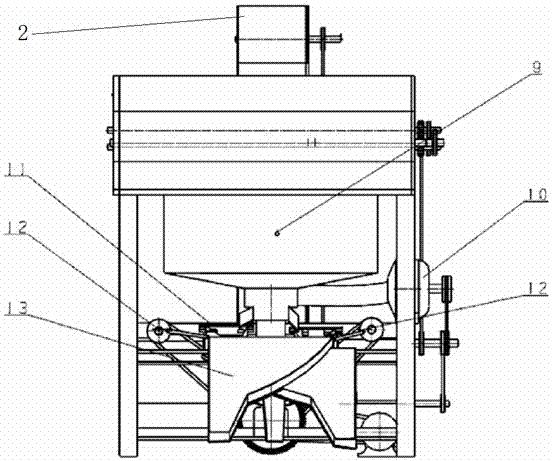

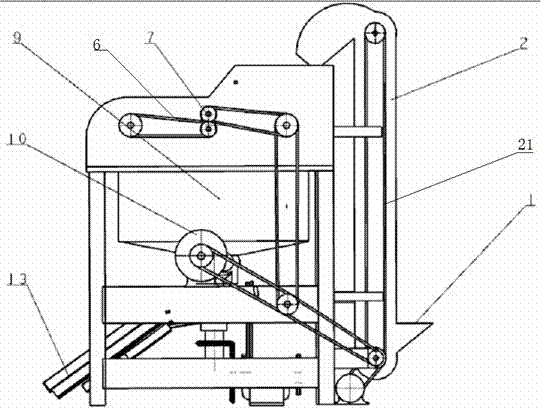

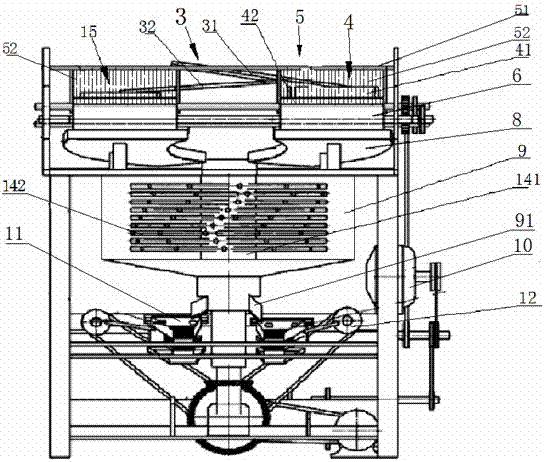

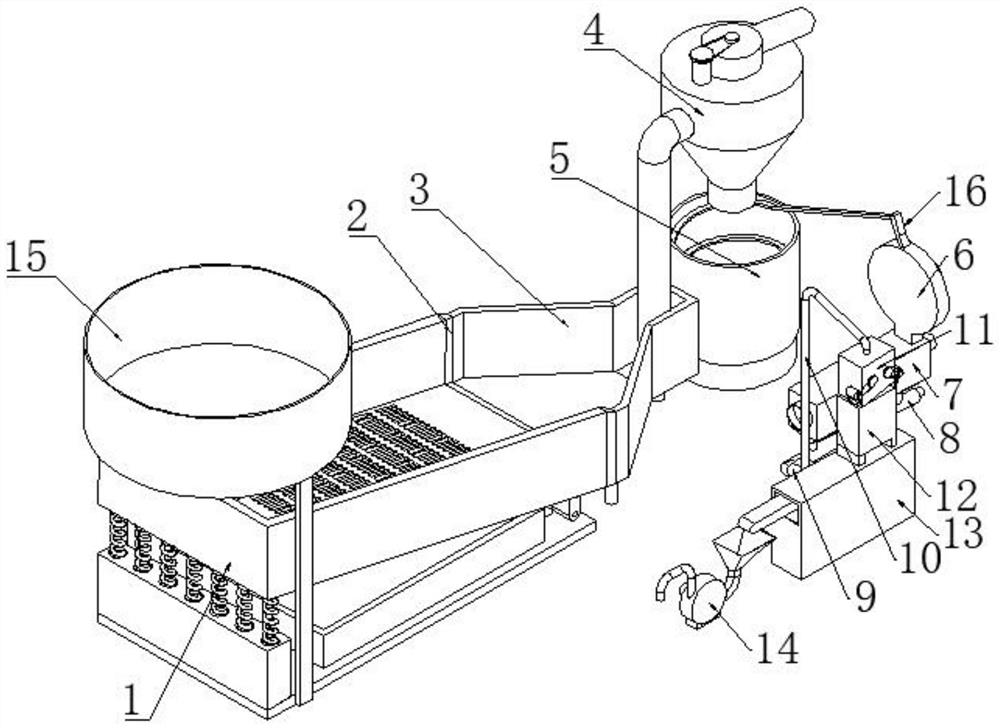

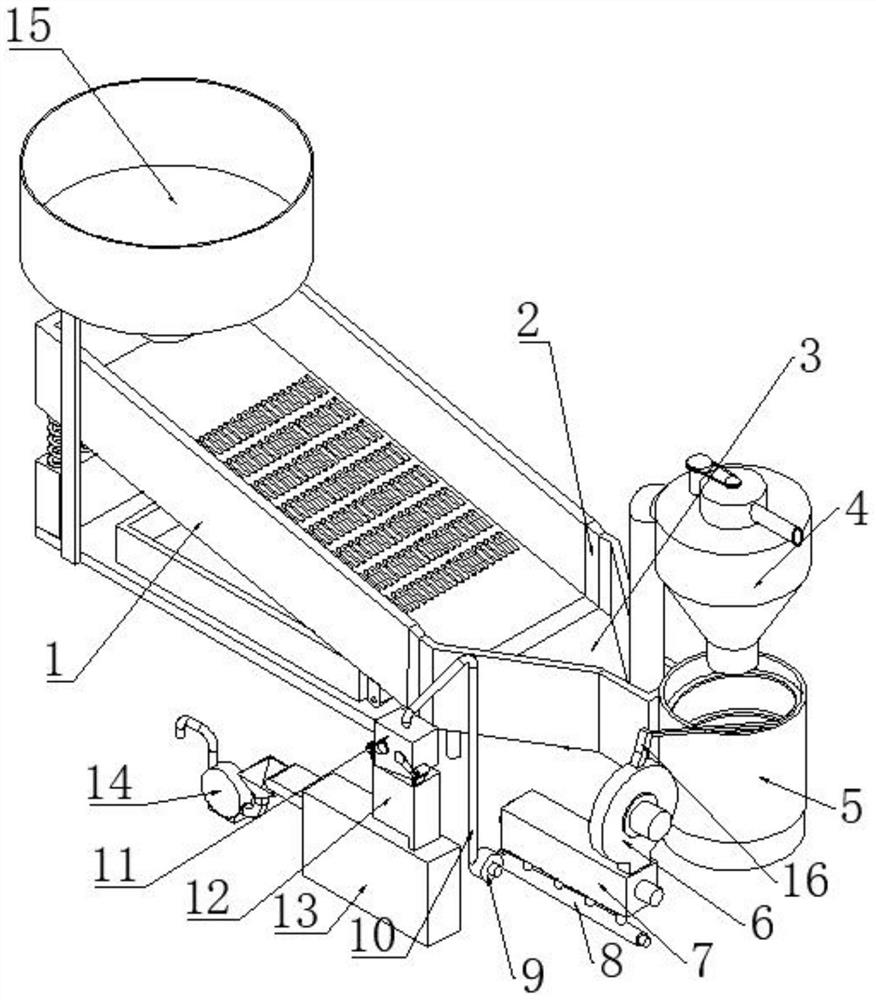

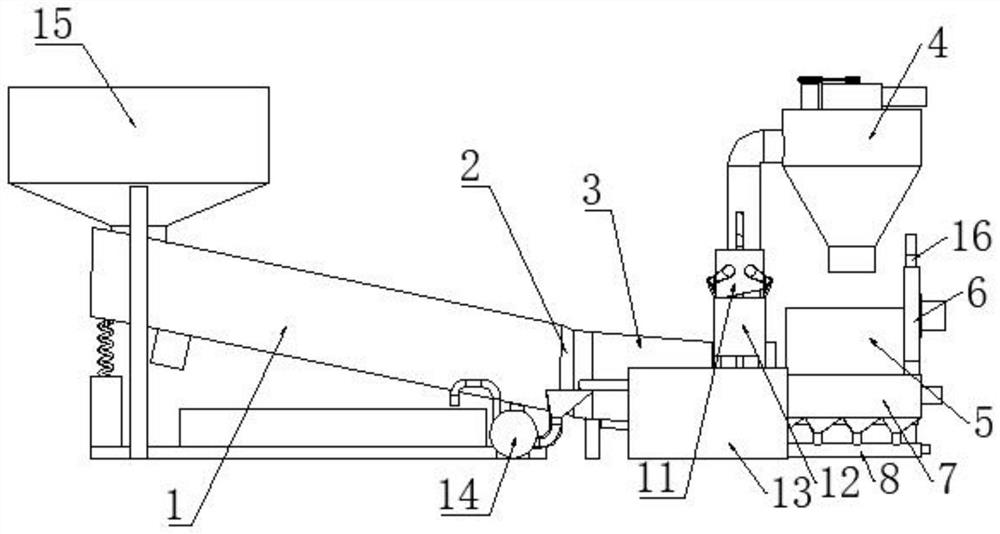

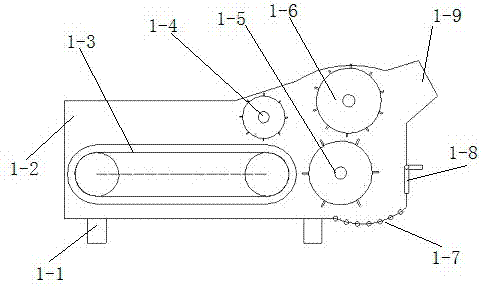

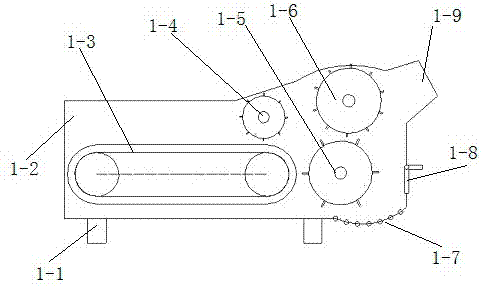

Hulling machine for sunflower seeds

ActiveCN105852157AGuaranteed cracking effectArranged horizontally evenlySievingScreeningEngineeringBrush device

The invention relates to a hulling machine for sunflower seeds. The hulling machine comprises a feeding hopper, a lifting conveying belt, a large and small seed separating sieve, an upper sieve vibrating device and a lower sieve vibrating device which are arranged below a material outlet at the top of the lifting conveying belt, grinding conveying belts arranged below the upper sieve vibrating device and the lower sieve vibrating device respectively, grinding rollers arranged in middles of the grinding conveying belts, brush devices arranged above the grinding conveying belts, arc-shaped collecting plates arranged at tail ends of the grinding conveying belts obliquely downwards, a rotating centrifugal barrel arranged below material outlets of the arc-shaped collecting plates, a centrifugal barrel discharging port arranged at the lower part of the rotating centrifugal barrel, a triple separating sieve arranged below the centrifugal barrel discharging port and multiple collecting tanks arranged at material outlets of all layers of the triple separating sieve, wherein the large and small seed separating sieve comprises an upper sieve and a lower sieve; the upper sieve extends obliquely downwards to above the upper sieve vibrating device; the lower sieve extends obliquely downwards to above the lower sieve vibrating device; sieve holes are formed in the upper sieve corresponding to the lower sieve.

Owner:巴彦淖尔市永明机械制造有限公司

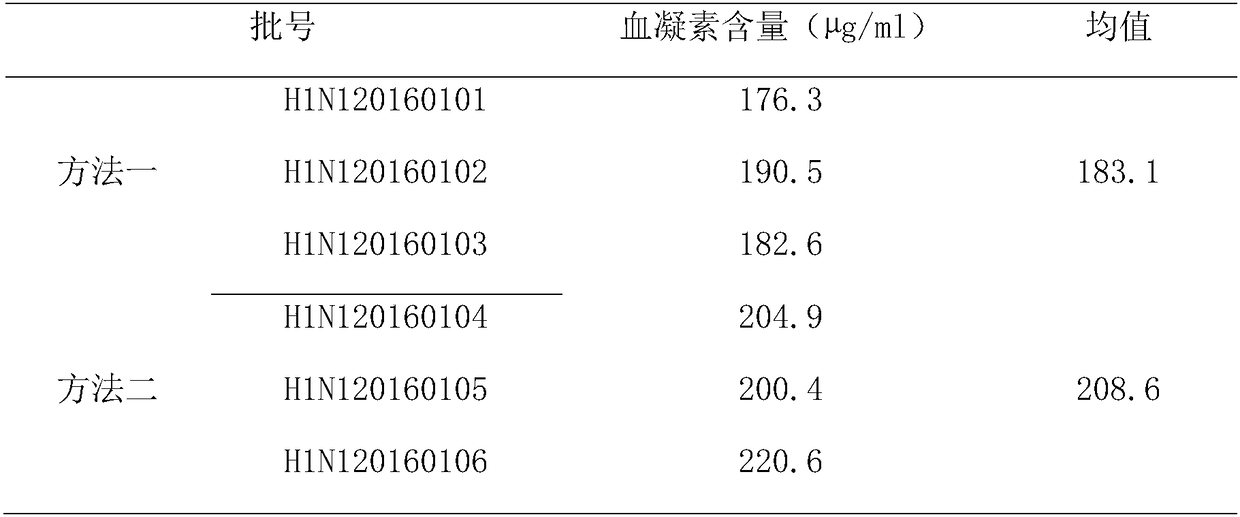

Influenza virus subunit vaccine purification method and applications thereof

InactiveCN108159411AImprove securityImprove effectivenessSsRNA viruses negative-senseViral antigen ingredientsPurification methodsVirus

The invention provides an influenza virus subunit vaccine purification method, which comprises a four-step purification technology, and a vaccine prepared thereby. The provided influenza virus subunitvaccine four-step purification technology overcomes the shortages of a conventional three-step purification technology; reduces the content of ovalbumin in the vaccine, enhances the virus splitting effect, and increases the contents of effective antigen substances such as HA.

Owner:AB&B BIO TECH CO LTD JS

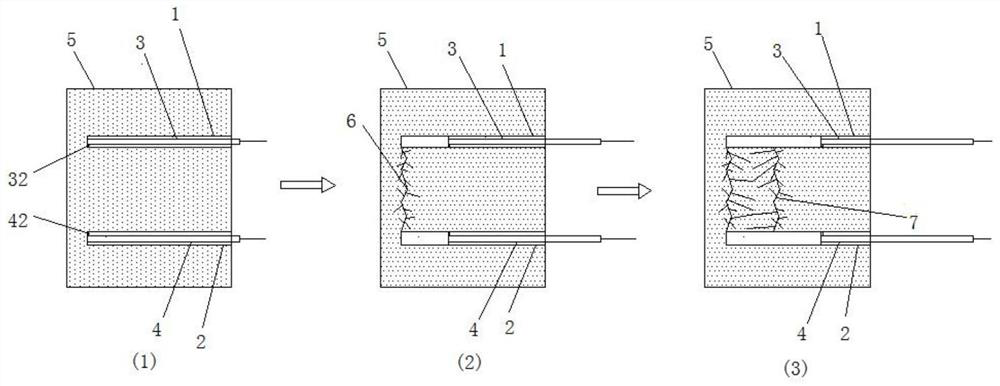

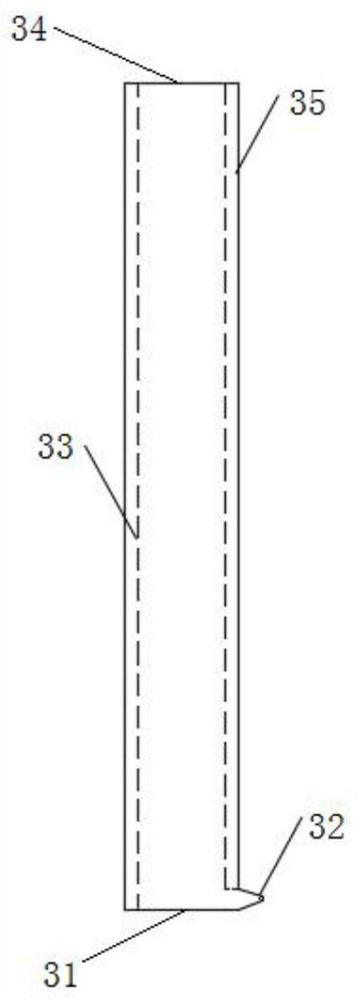

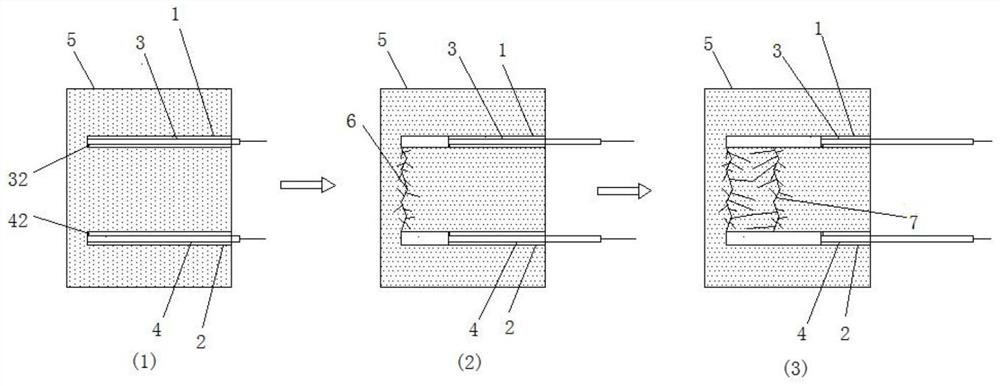

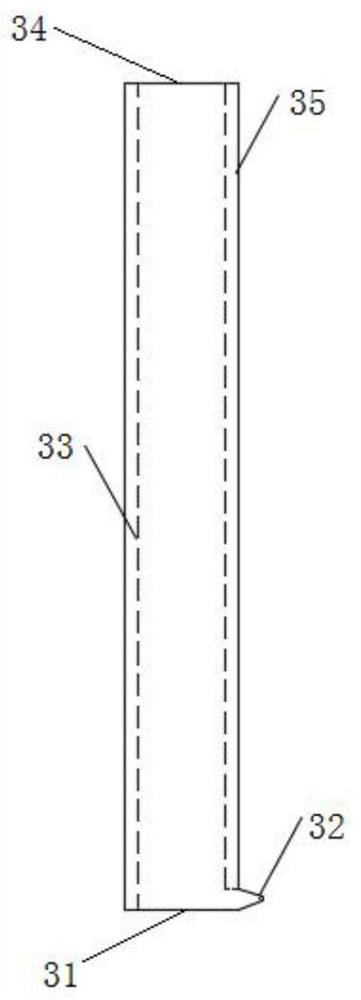

Hard rock pre-damage and rupture method based on high-voltage pulse electrical explosion

ActiveCN111912309AChange pre-injuryChange direction of ruptureBlastingVoltage pulseHigh voltage pulse

The invention discloses a hard rock pre-damage and rupture method based on high-voltage pulse electric explosion. and belongs to the technical field of rock mass rupture. The hard rock pre-damage andrupture method comprises the following steps: 1, two holes, namely a first drill hole and a second drill hole, are drilled in a to-be-ruptured rock mass; 2, the first discharge electrode bottom end ofof a first discharge electrode is inserted into the first drill hole, and the second discharge electrode bottom end of a second discharge electrode is inserted into the second drill hole; and 3, if the first discharge electrode and the second discharge electrode are inserted into the hole bottoms firstly when inserted into the first drill hole and the second drill hole for the first time, rock mass pre-damage operation is conducted, and if the first discharge electrode and the second discharge electrode are inserted into the edges of orifices firstly when inserted into the first drill hole and the second drill hole for the first time, rock mass breaking operation is conducted. The method is safe, reliable, environment-friendly and efficient, and can be suitable for various scenes such asrock pre-damage of hard boulders, mine field mining and mine field rock large block crushing during excavation of a shield tunneling machine.

Owner:NORTHEASTERN UNIV

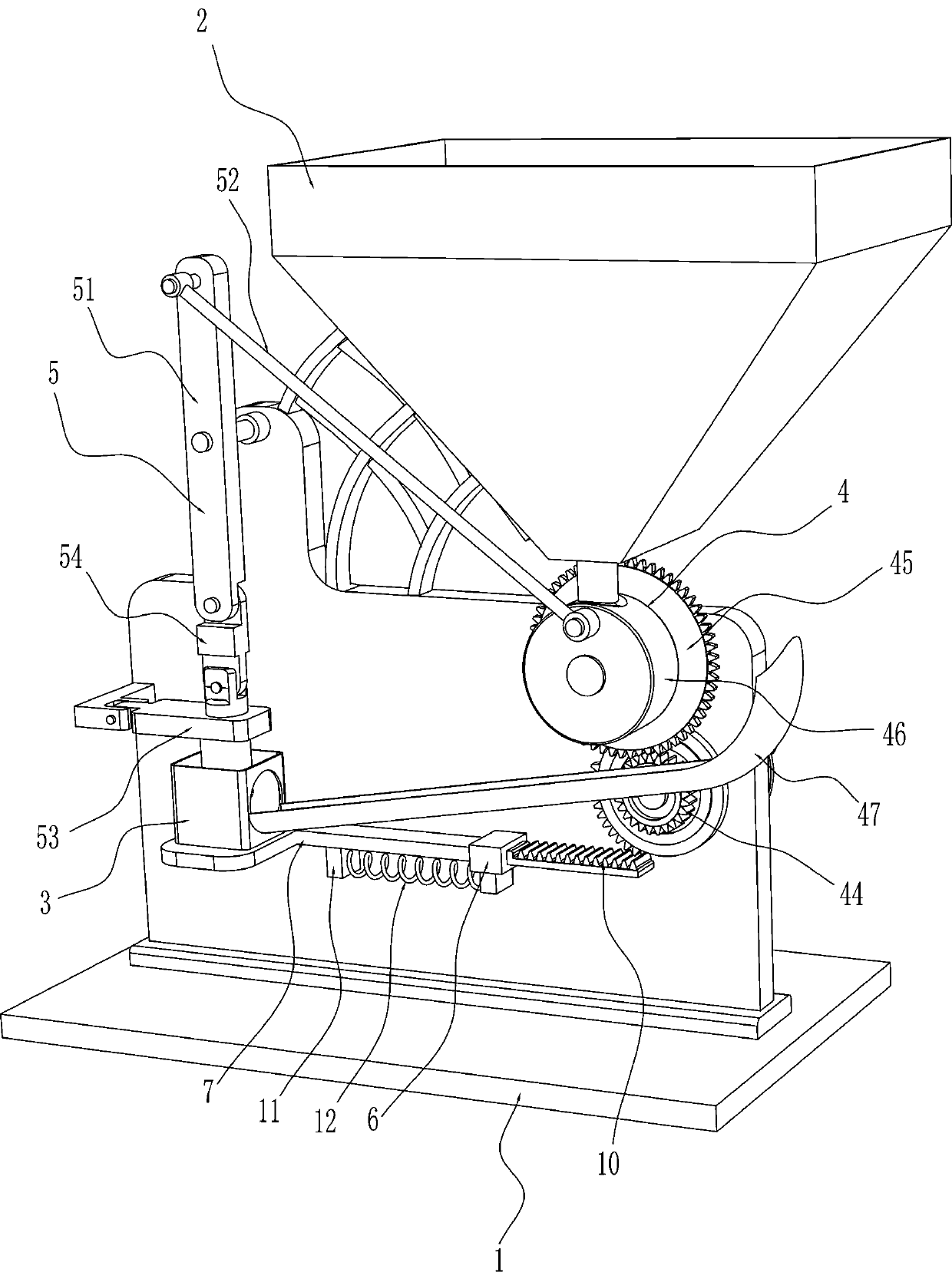

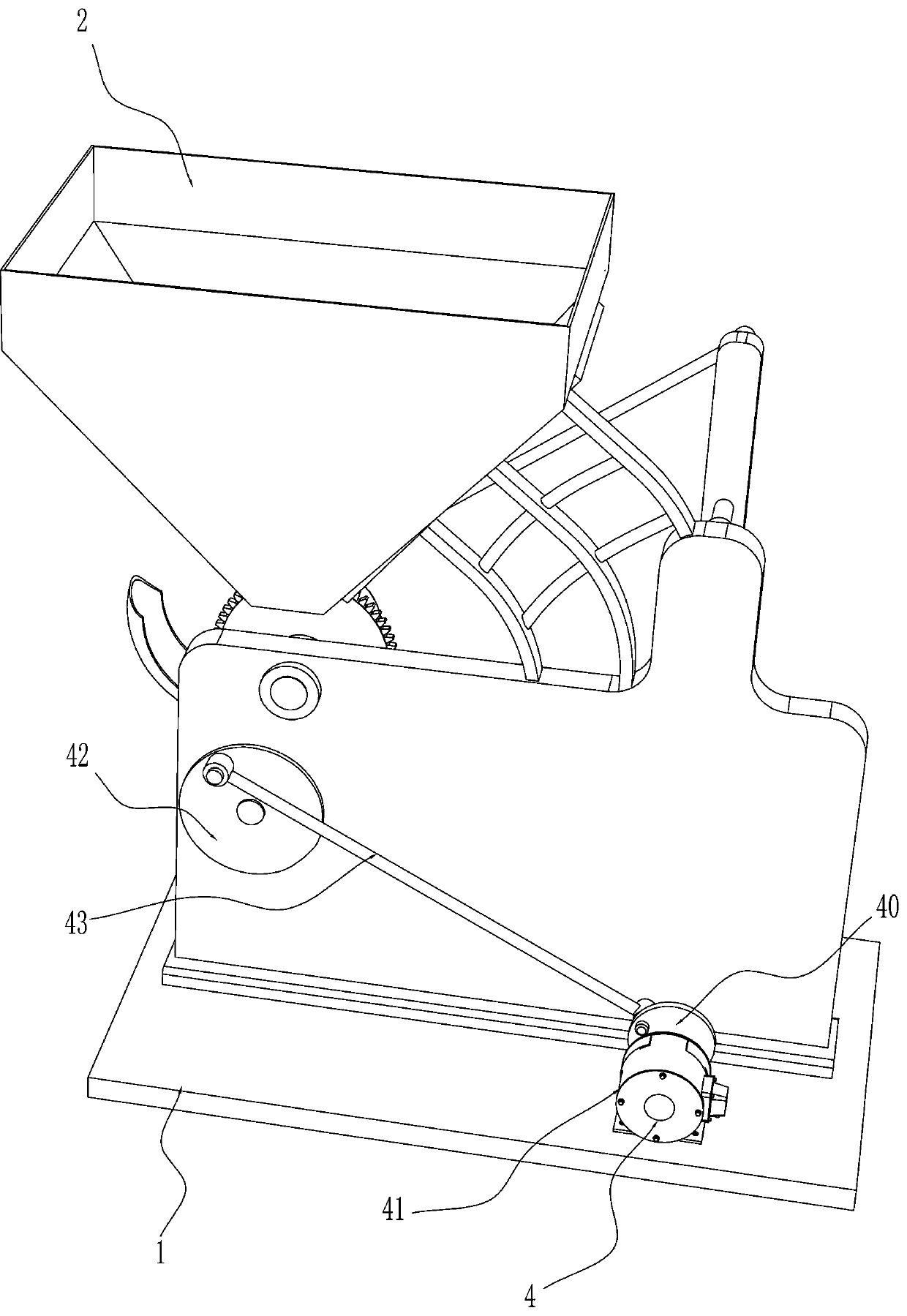

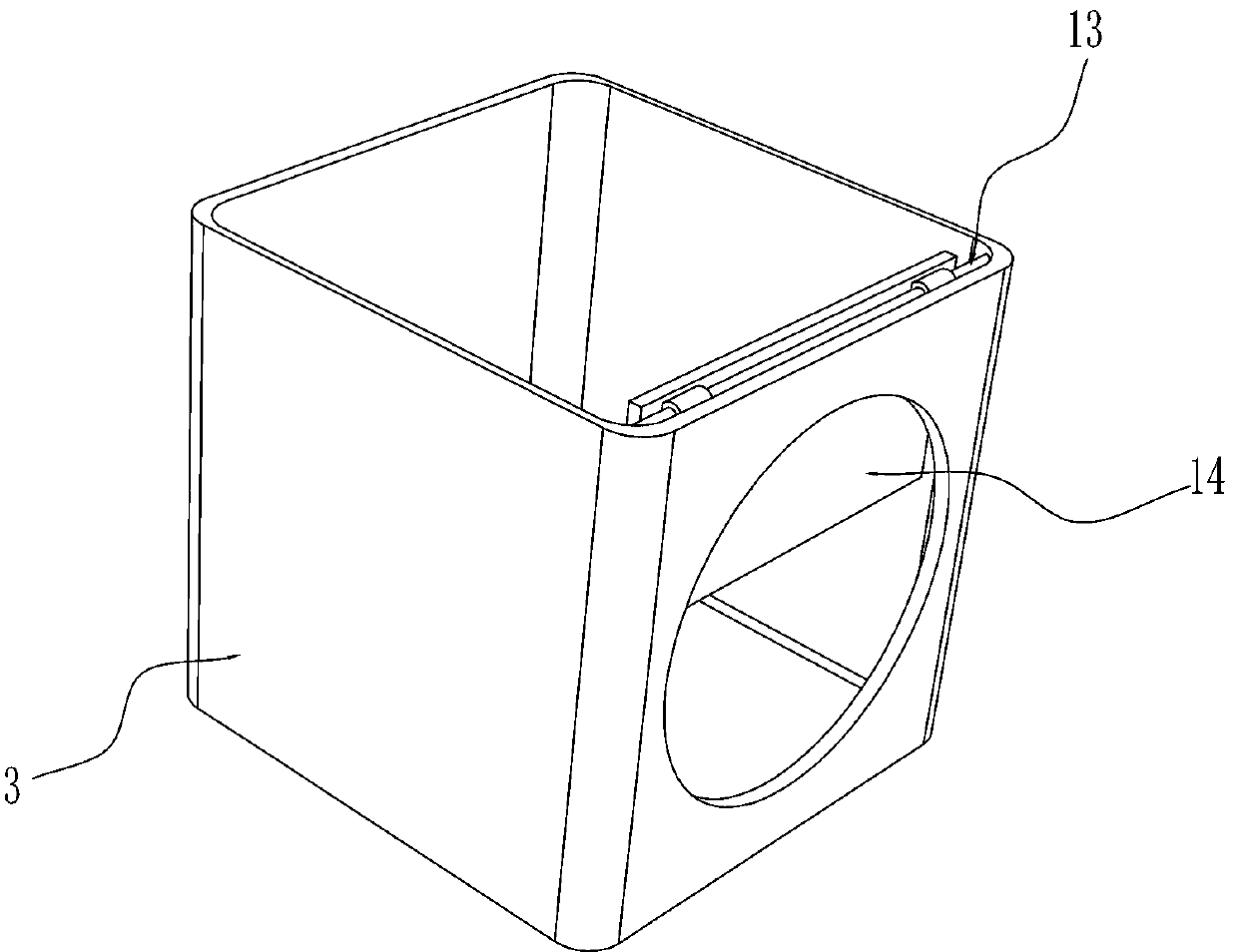

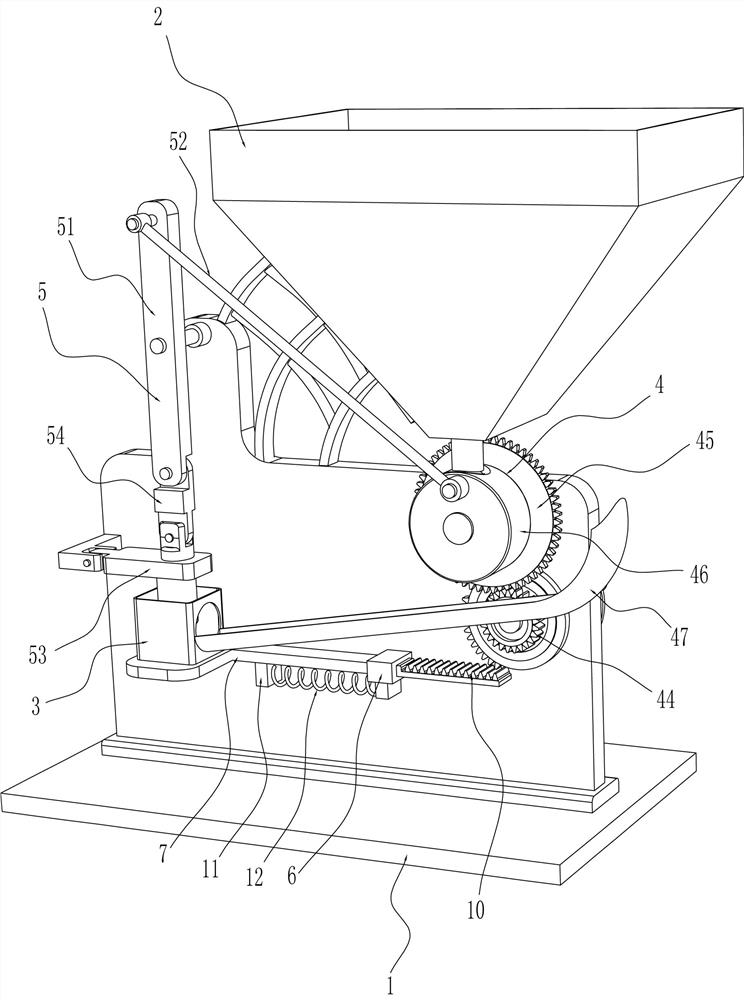

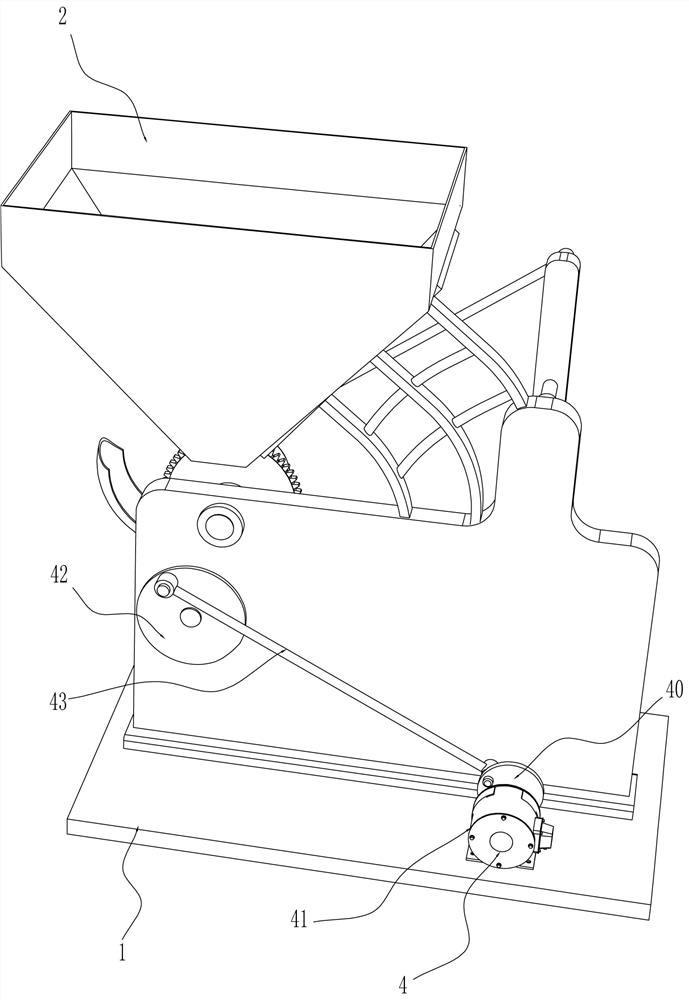

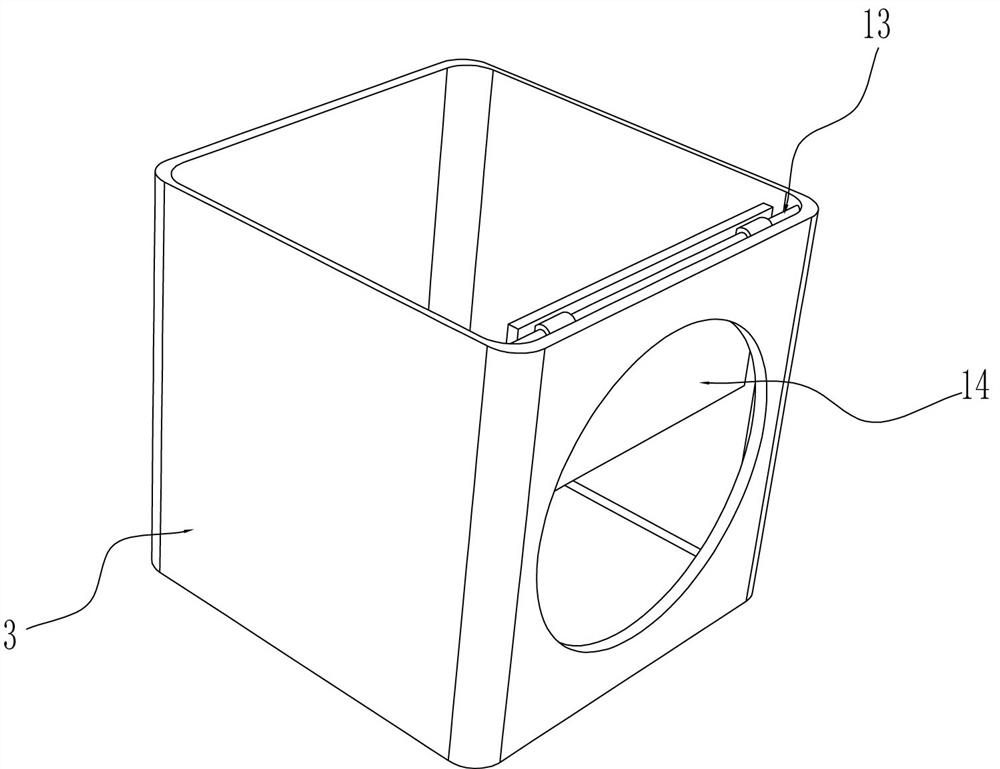

Camellia fruit shell crushing device for grain and oil processing

ActiveCN111495467AEfficient crushingNo manual operationFatty-oils/fats productionHuskingOil processingAgricultural engineering

The invention relates to the technical field of grain and oil processing, in particular to a camellia fruit shell crushing device for grain and oil processing. The camellia fruit shell crushing devicefor grain and oil processing aims to achieve the effects of being high in shell crushing efficiency and not needing manual operation. The camellia fruit shell crushing device for grain and oil processing comprises a machine frame, a material bin, a crushing frame, a feeding mechanism, a shell crushing mechanism, a guide sleeve, a support plate and the like. The material bin is arranged on the topof the machine frame. A crushing frame is fixedly connected with one side of the lower portion of the machine frame. The other side of the lower portion of the machine frame is provided with the feeding mechanism. The side, close to the feeding mechanism, of the crushing frame is provided with a feeding opening. The shell crushing mechanism is arranged on the part, located above the crushing frame, of the machine frame. The guide sleeve is fixedly connected to the middle of the lower part of the machine frame. The support plate is arranged in the guide sleeve in a sliding manner. Through cooperation between the feeding mechanism and the shell crushing mechanism, the camellia fruit shell crushing device for grain and oil processing can effectively crush camellia fruits, does not need manual operation and saves labor.

Owner:邓志杰

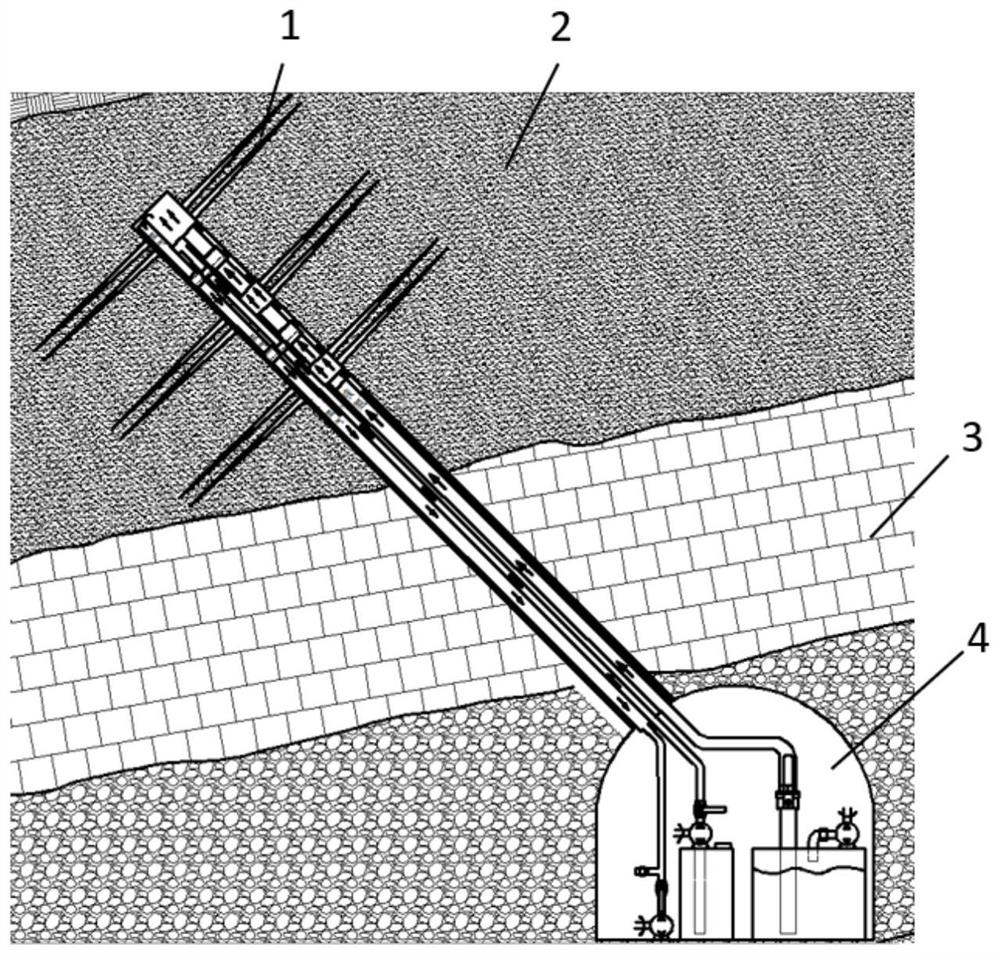

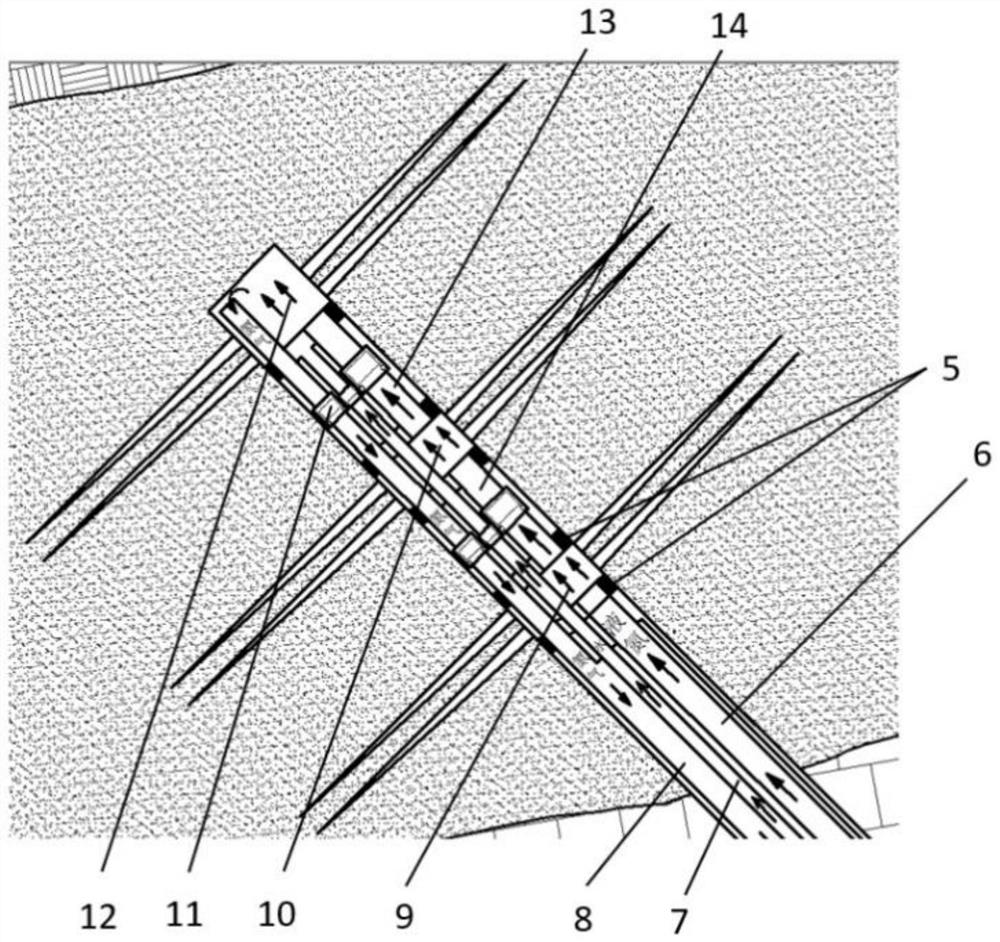

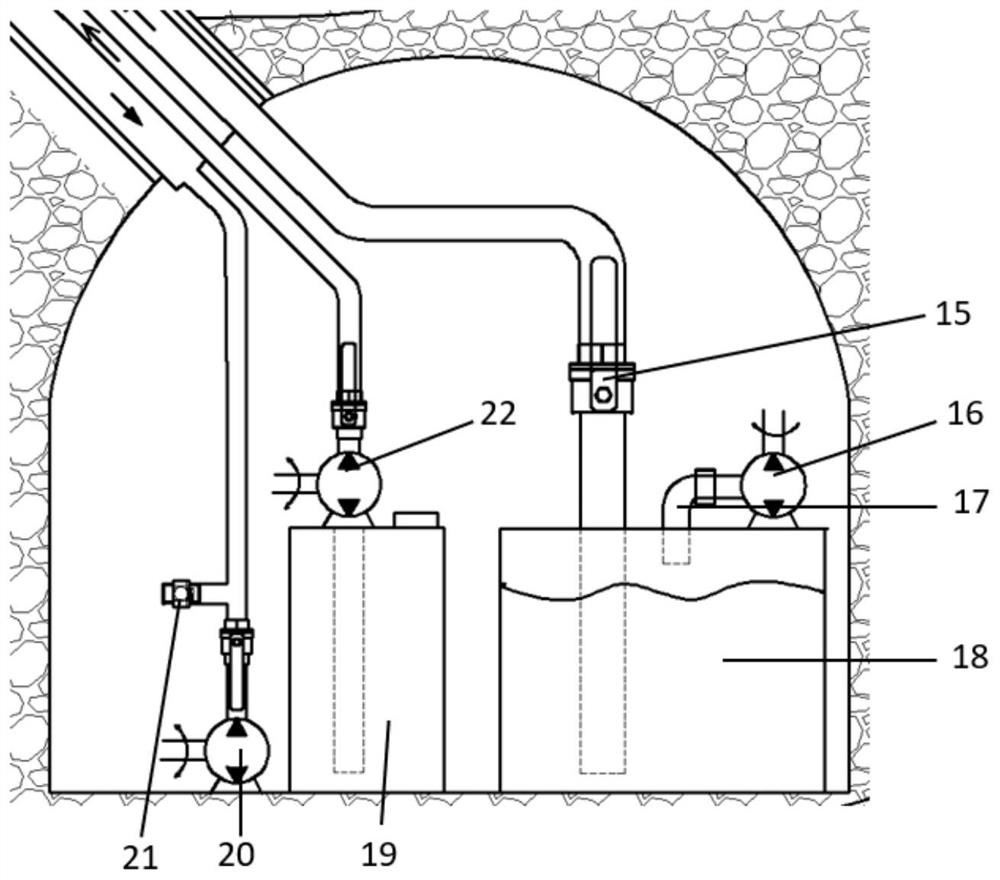

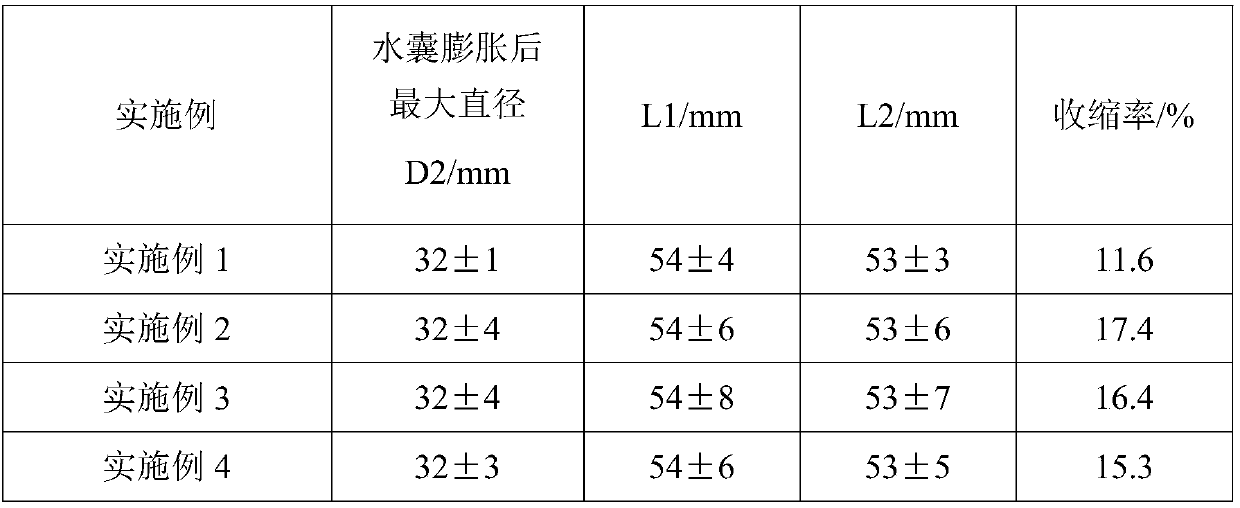

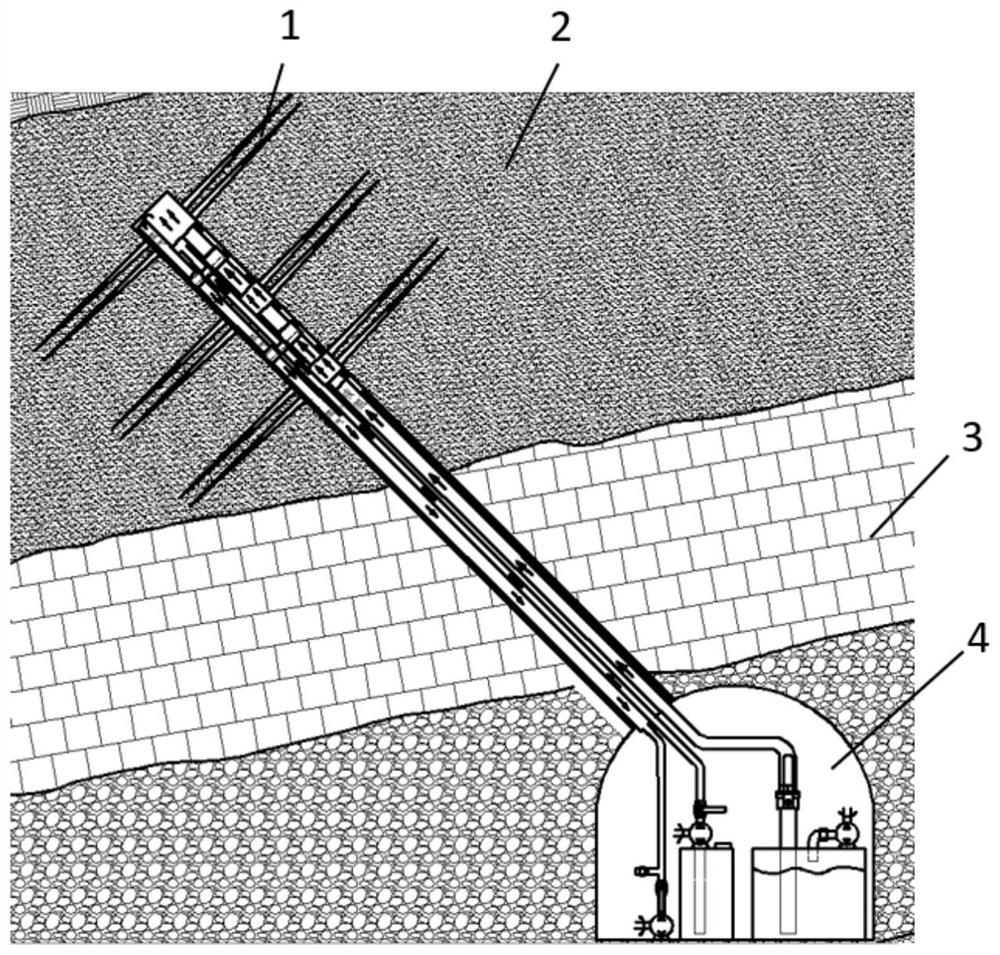

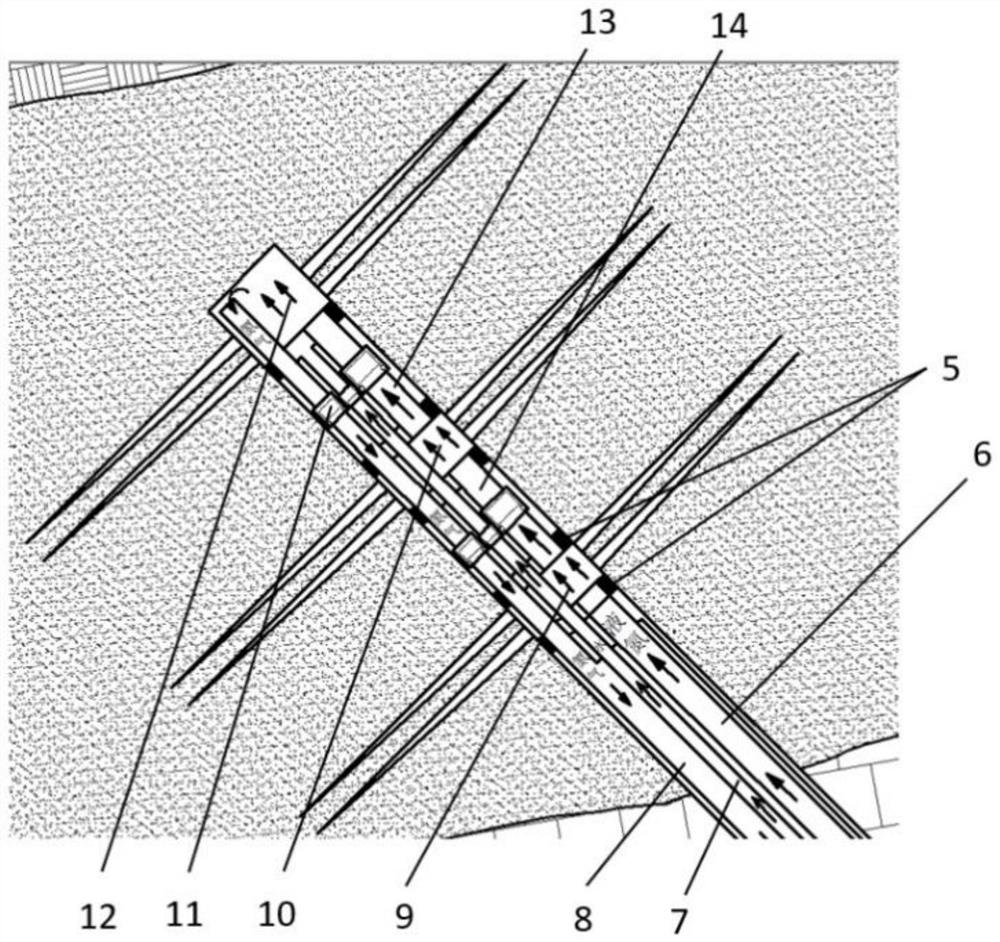

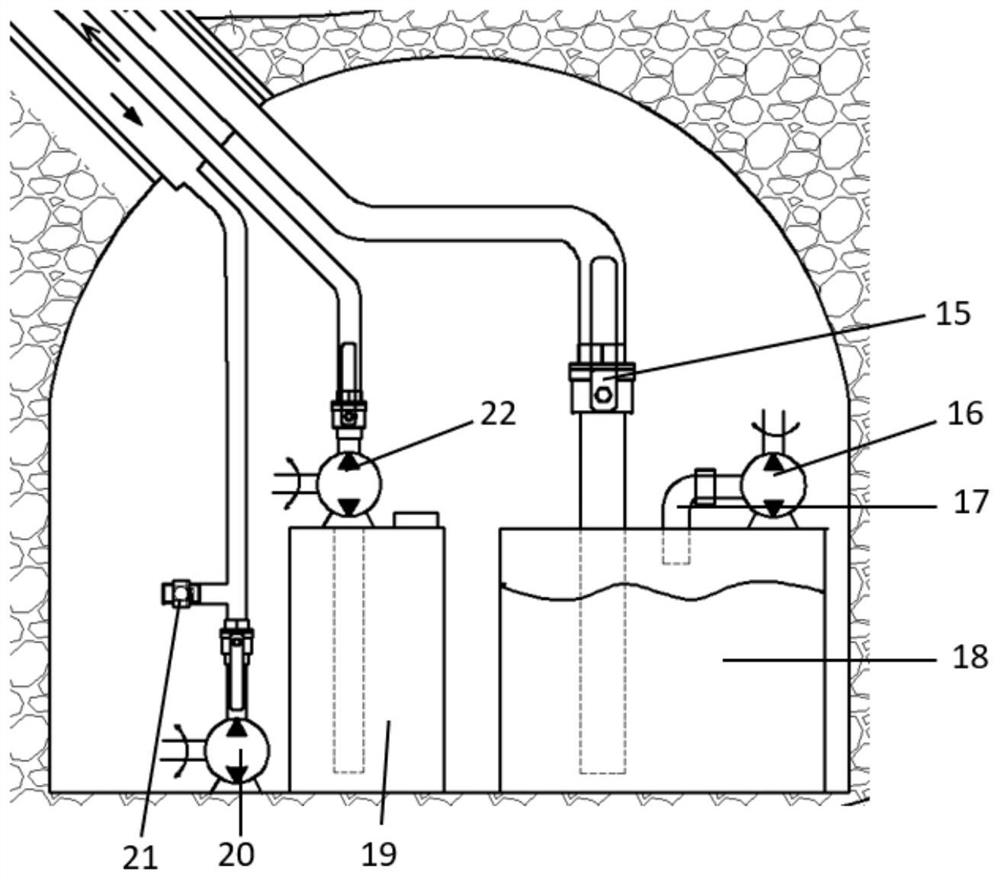

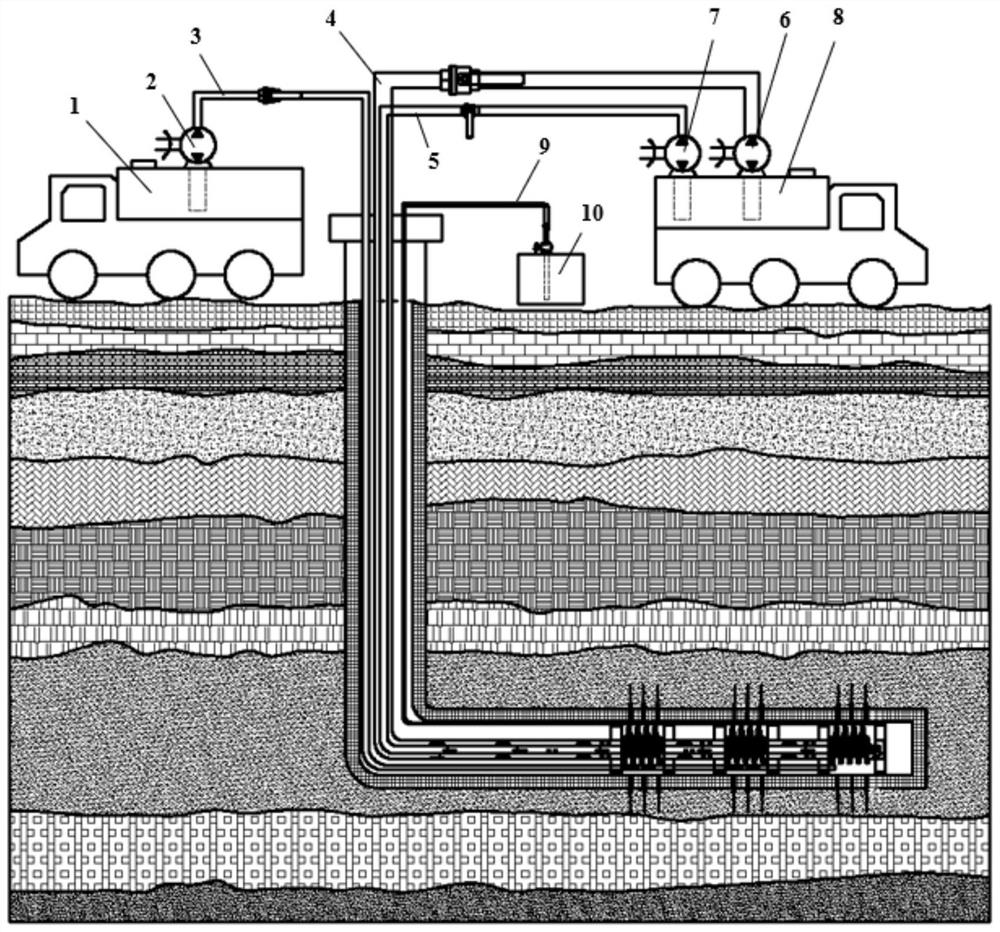

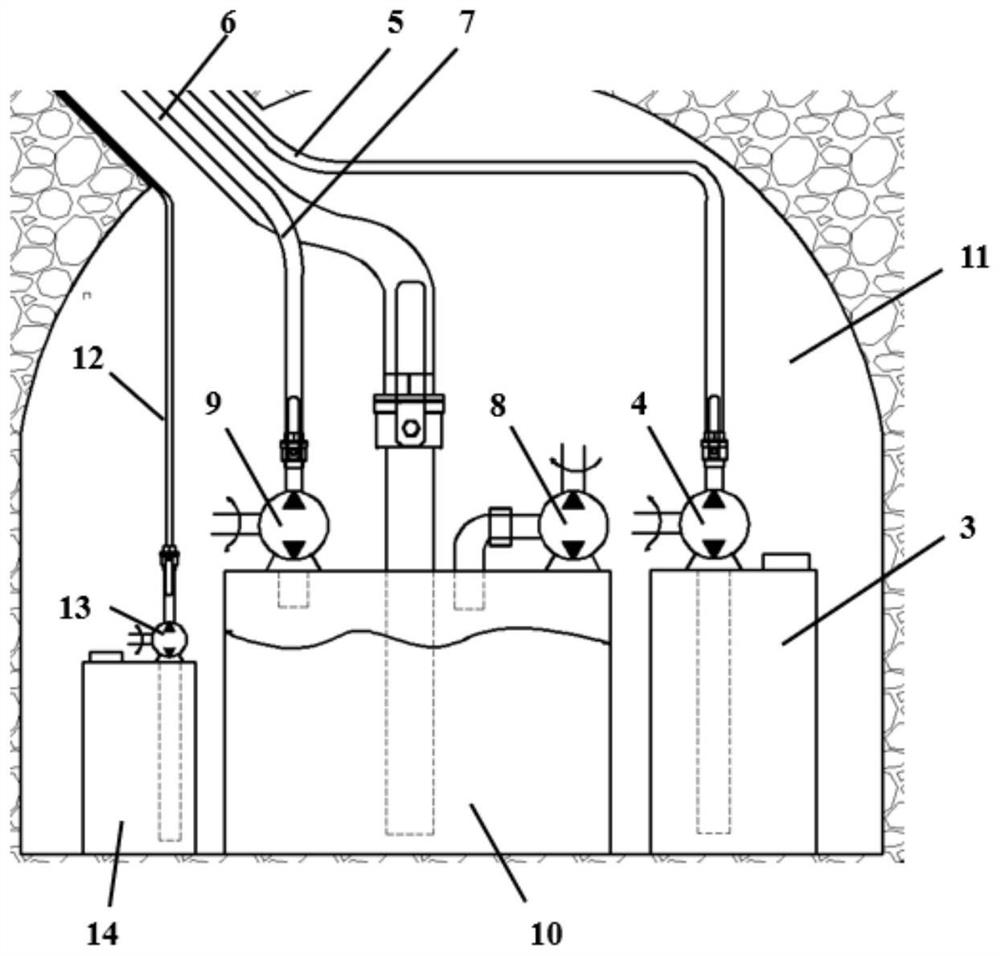

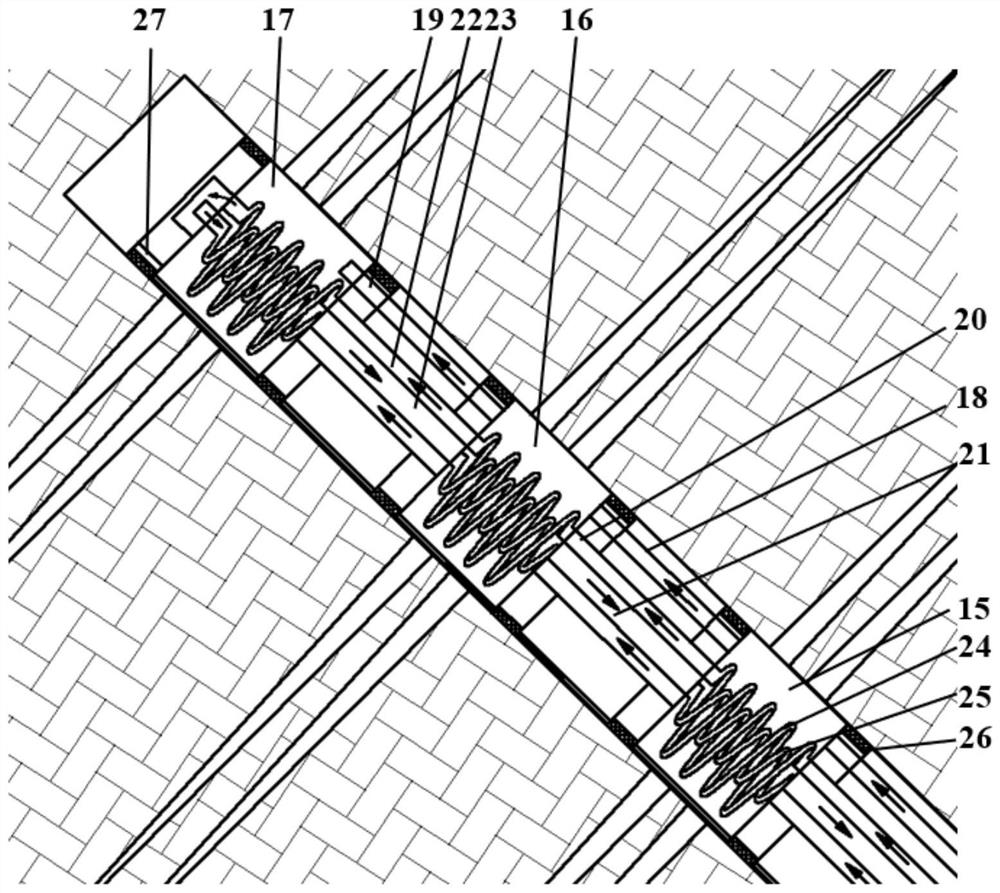

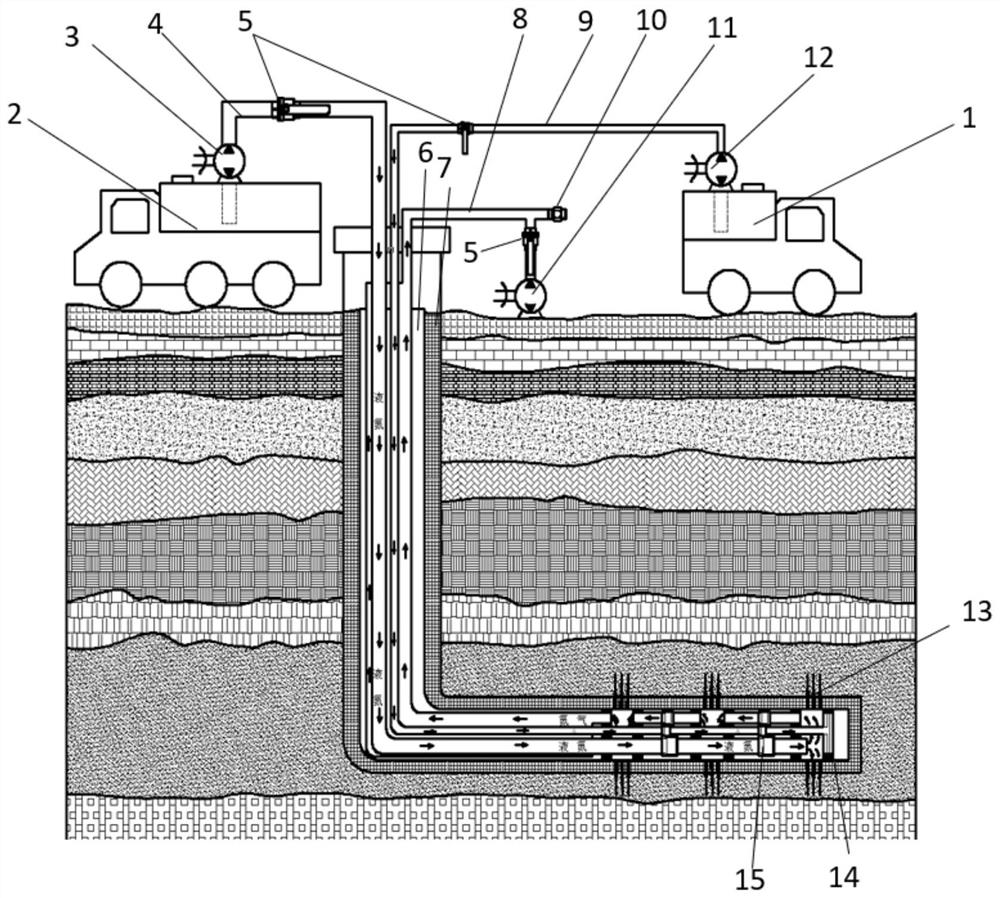

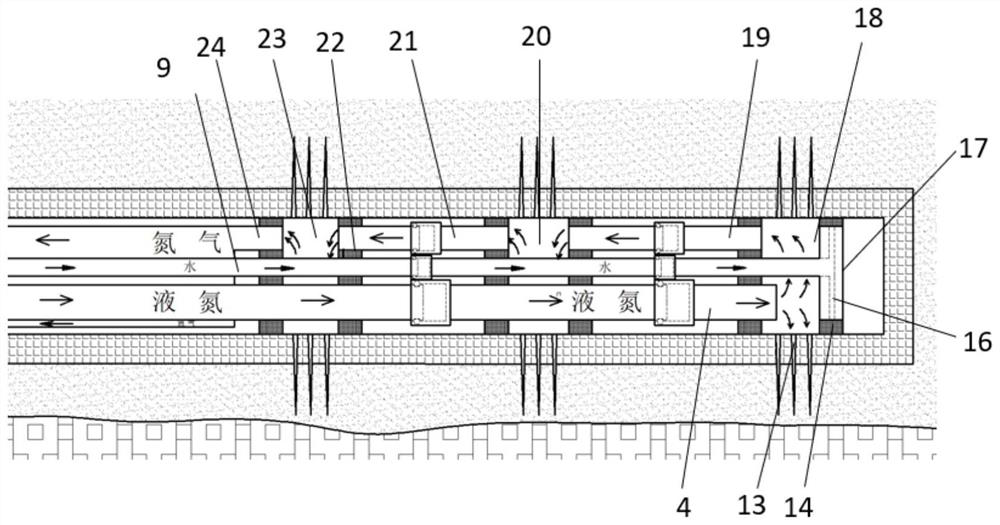

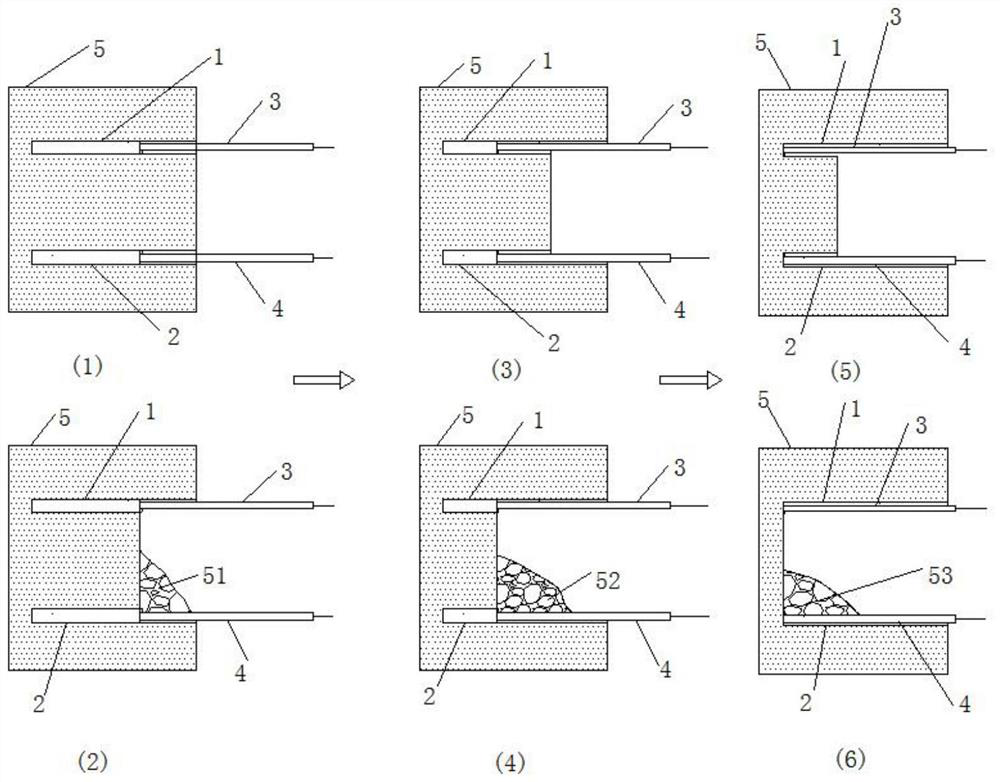

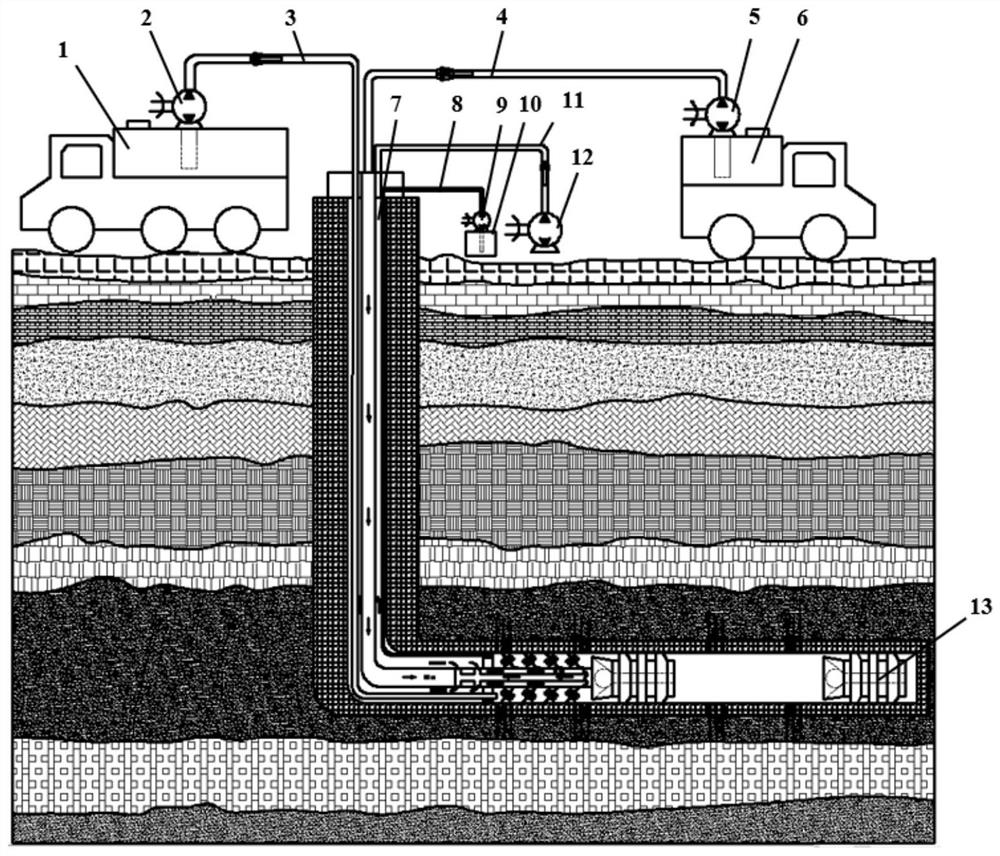

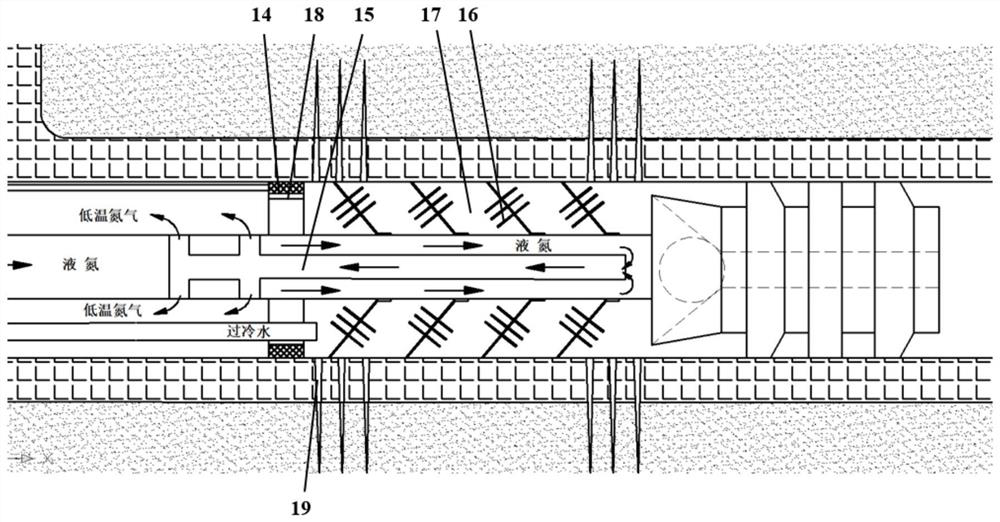

Uphole negative-pressure advancing-type cryogenic fluid injection segmented cyclic fracturing method

The invention discloses an uphole negative-pressure advancing-type cryogenic fluid injection segmented cyclic fracturing method. According to the method, firstly, water jet slotting equipment is adopted for arranging three fracture areas; water is injected through a water injection pipe so that hydraulic plugging devices can be filled up to form three hermetic fracturing chambers, the three hermetic fracturing chambers are put in a negative-pressure state, and the cryogenic fluid is injected in the hermetic fracturing chambers to fill the hermetic fracturing chambers in sequence and conduct cold shock fracturing on the fracture areas in the three hermetic fracturing chambers; as the cryogenic fluid in the hermetic fracturing chambers is heated up and gasified under the influence of terrestrial heat, a safety relief valve is opened to exhaust the phase-change gas after gas pressure inside a cryogenic fluid exhaust pipe exceeds an opening threshold value of the safety relief valve, thusthe gas pressure inside the cryogenic fluid exhaust pipe and all the hermetic fracturing chambers is lowered, and through the repetitive cycle, the hermetic fracturing chambers are subject to multipletimes of fracturing under gas expansion force. By means of the method, rapid injection of the cryogenic fluid and the fracturing effect on coal and rock mass can be effectively guaranteed, and pollution to the surrounding environment can also be avoided.

Owner:CHINA UNIV OF MINING & TECH

Cauliflower vegetable root cleaning device for clean vegetable processing

ActiveCN108835668AGuaranteed effective cleaningPlay a fixed effectFood treatmentDrive motorEngineering

The invention discloses a cauliflower vegetable root cleaning device for clean vegetable processing, and relates to the technical field of vegetable processing. The cauliflower vegetable root cleaningdevice for clean vegetable processing comprises a machine body, the left side of the machine body is in inserted connection with a feeding frame, the feeding frame is communicated with an inner cavity of the machine body, the machine body is internally, transversely and movably provided with a conveyor belt, the conveyor belt is located under the right side of the feeding frame, the right end ofthe conveyor belt is driven by a driving motor, the driving motor is fixedly arranged at the right side of the bottom in the machine body, and a cleaning box is arranged under the right side of the conveyor belt. The cauliflower vegetable root cleaning device for clean vegetable processing fixes cauliflowers located on the conveyor belt through barbs, cuts vegetable roots through a blade, and thecauliflowers after roots are removed and fall into the cleaning box for cleaning along with the transmission of the conveyor belt, thereby effectively ensuring effective cleaning in the cauliflowers and solving the problem that an existing cauliflower cleaning device cannot fully clean the inner portions of the cauliflowers.

Owner:澄果制药(山东)股份有限公司

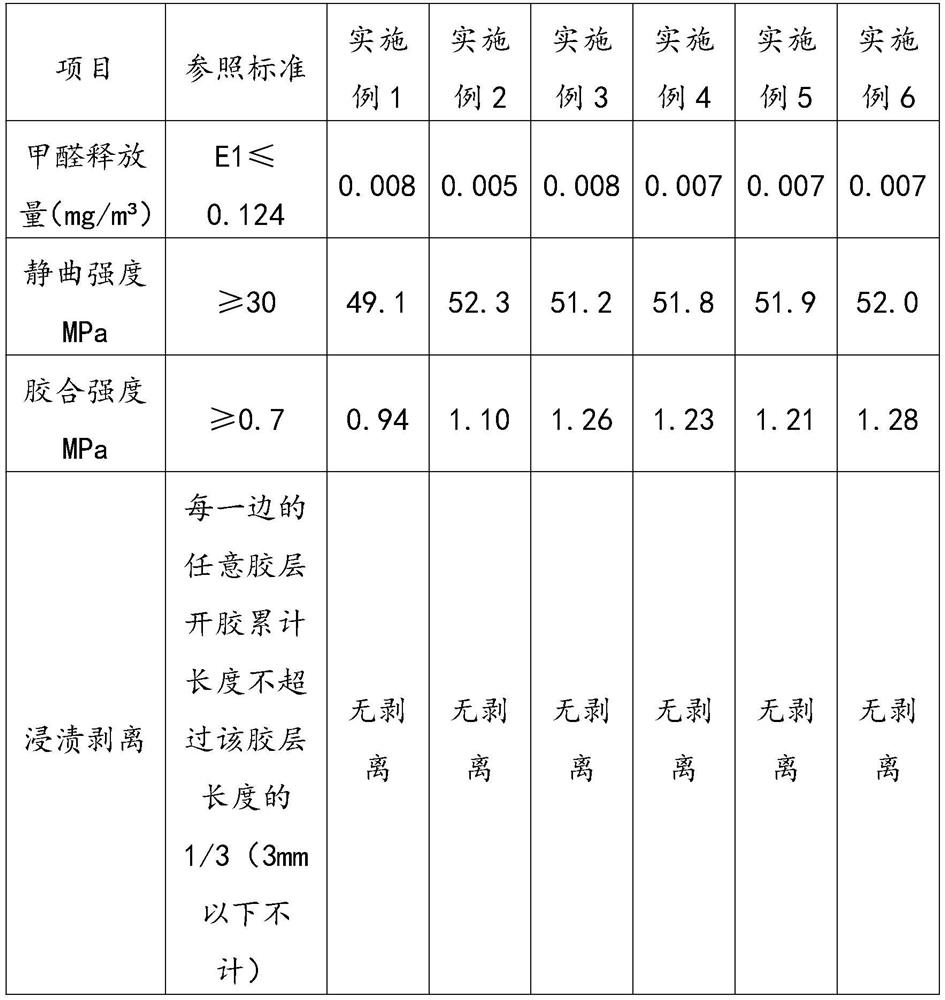

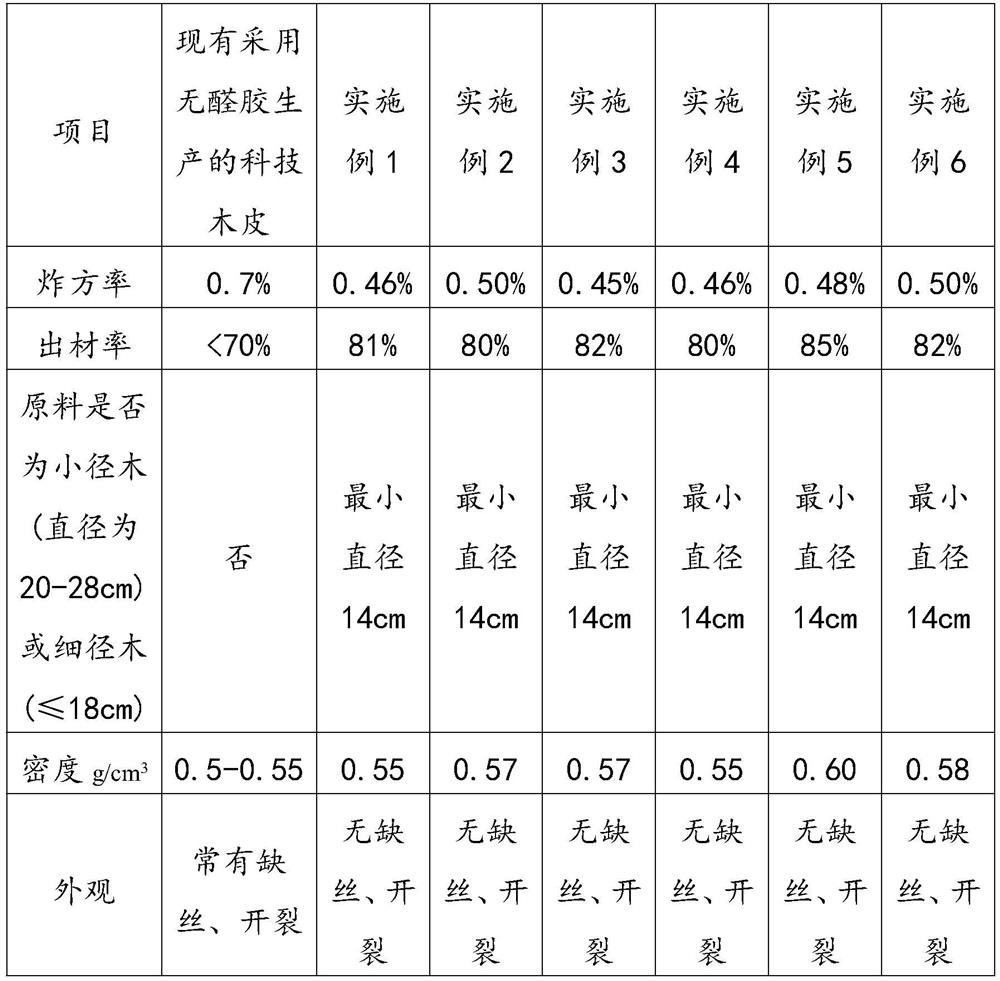

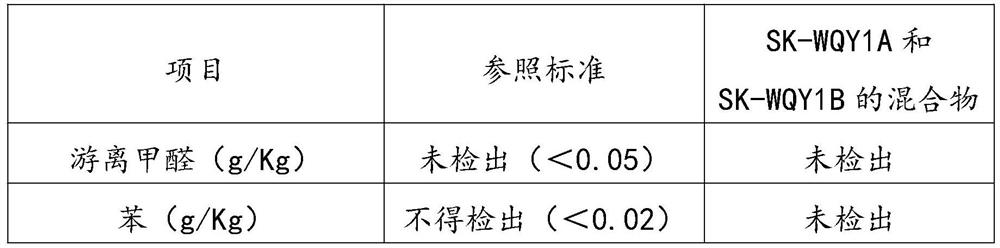

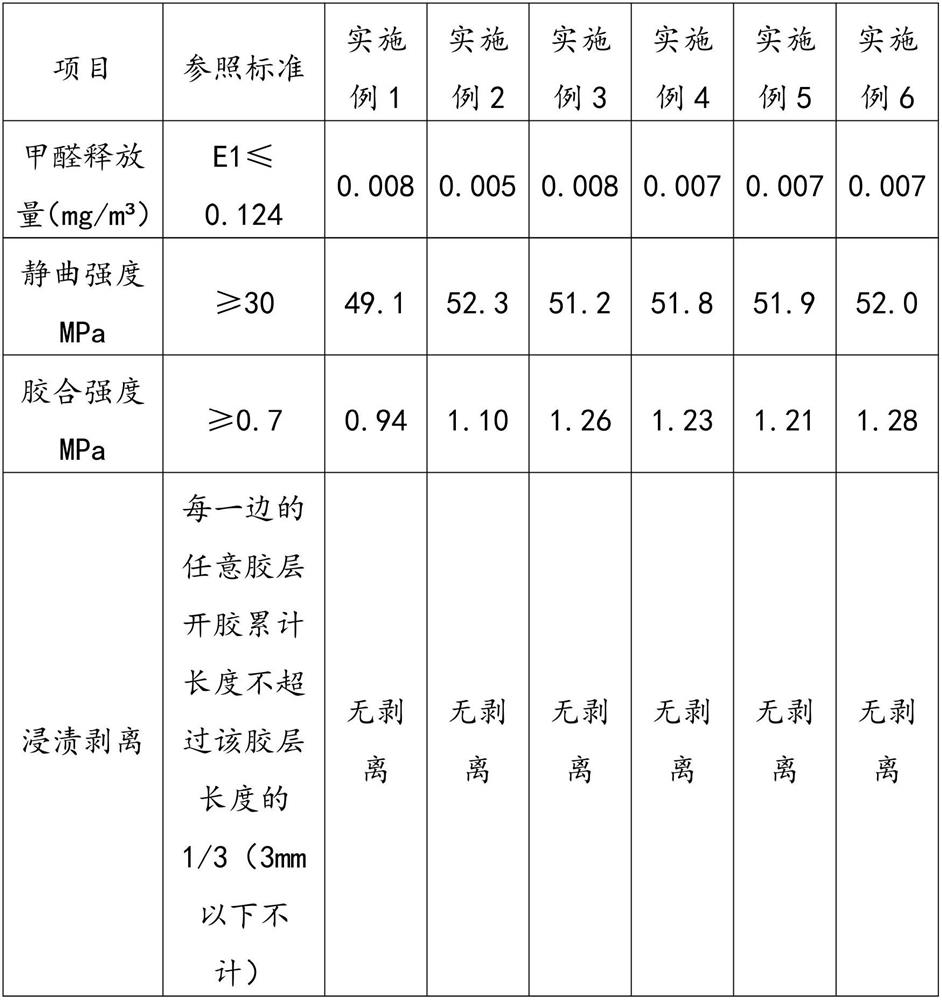

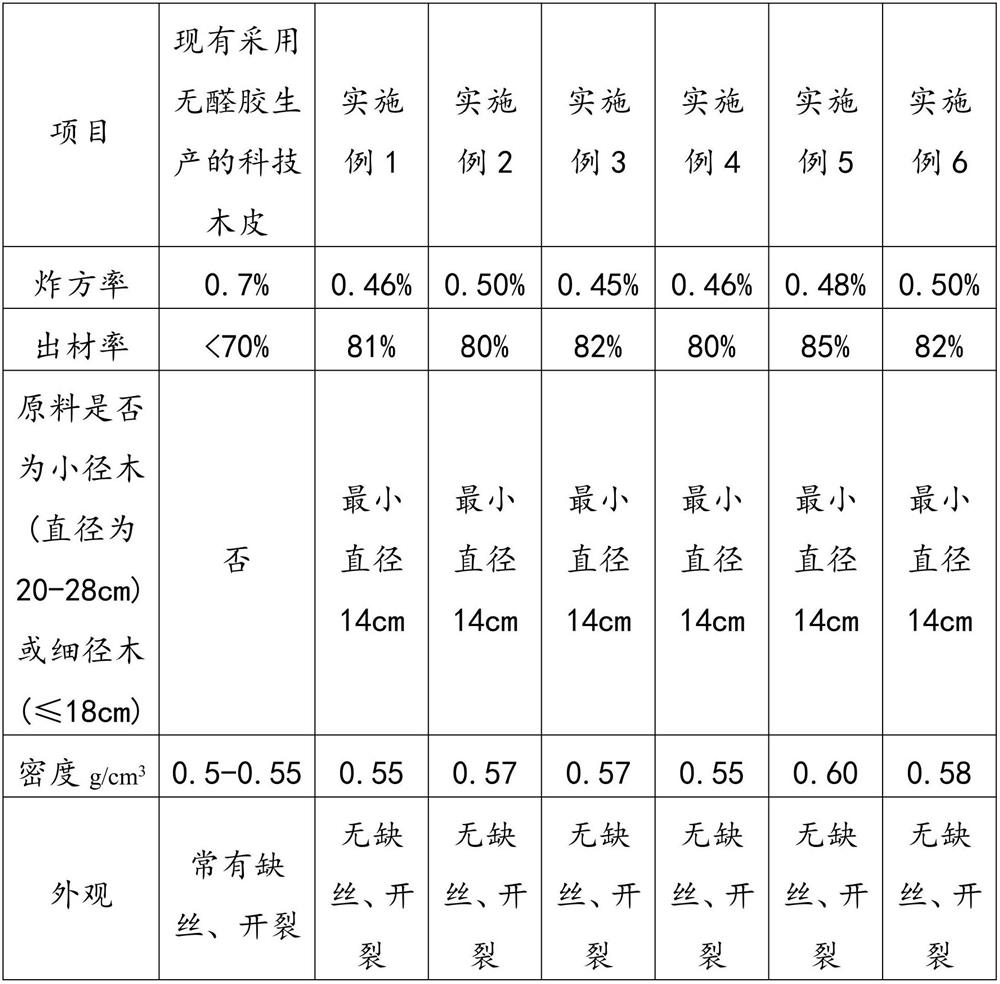

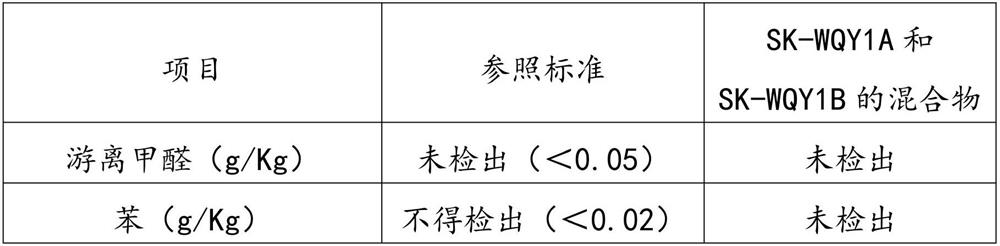

Production method of aldehyde-free technical wood veneer used for veneer solid wood multilayer board assembly

ActiveCN111823336AImprove performanceGood sizingWood treatment detailsThermal wood treatmentAdhesive glueEnvironmentally friendly

The invention relates to a production method of an aldehyde-free technical wood veneer used for a veneer solid wood multilayer board assembly. The production method sequentially comprises the steps of(1) drying and repairing an economical fast-growing wood wet veneer; (2) assembling the processed economical fast-growing wood wet veneer, coating aldehyde-free glue, and carrying out cold pressing to form a board blank; (3) carrying out pressure maintaining and high-frequency microwave heating on the board blank; (4) carrying out primary maintenance; (5) carrying out secondary maintenance; and (6) milling the board blank to remove burrs, and planing and cutting the board blank into the aldehyde-free technical wood veneer. According to the production method, the defects that existing small-diameter wood and thin-diameter wood can only be used for manufacturing shaving boards, and the use amount of glue is large, so that the shaving boards are not environmentally friendly are overcome; through the cooperation of the aldehyde-free glue of the optimized type, the optimized glue amount and the optimized assembly production process, the aldehyde-free technical wood veneer with good performance can be produced by using the small-diameter wood and the thin-diameter wood; and not only is the aldehyde-free technical wood veneer low in harmful substance content and environmentally friendly,but also the problems of breakage, burrs, cracks and the like in the production process can be effectively reduced.

Owner:小森新材料科技有限公司

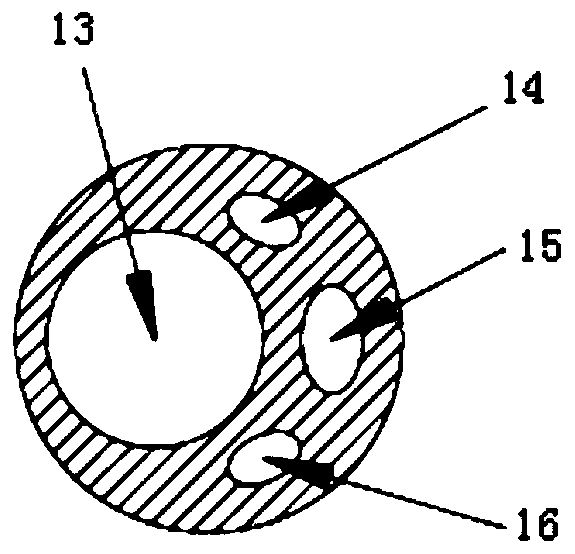

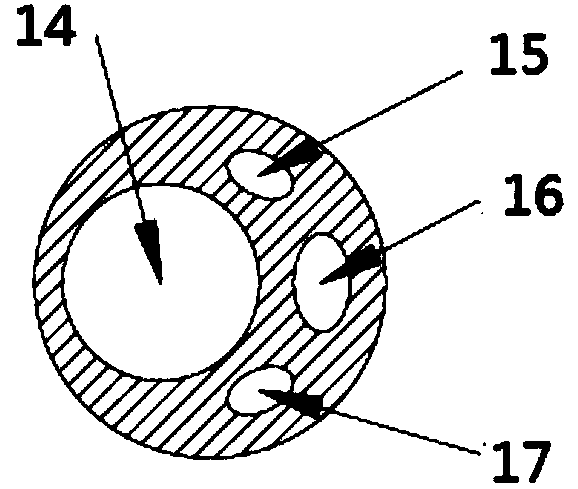

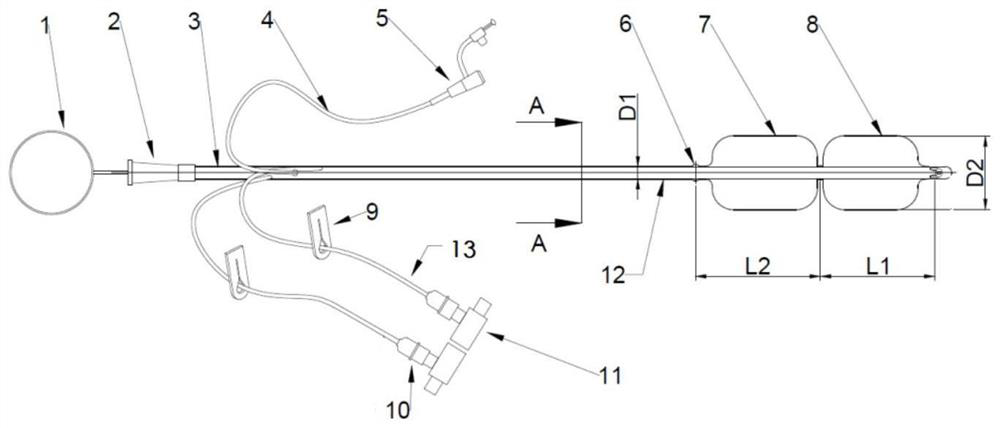

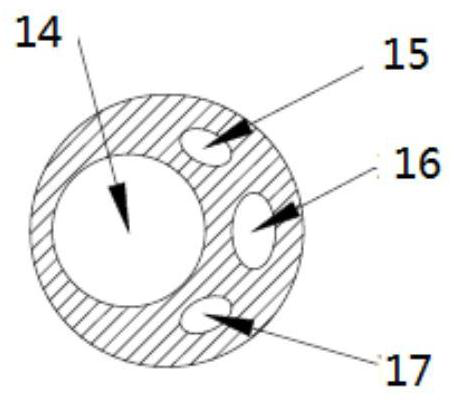

Traditional Chinese medicine composition for medical catheter

InactiveCN109700895APrevent urinary incontinencePrevent bleedingAntibacterial agentsAntipyreticMagnolia bark extractUrinary incontinence

The invention relates to the field of traditional Chinese medicine, in particular to a traditional Chinese medicine composition for a medical catheter. The traditional Chinese medicine composition forthe medical catheter comprises officinal magnolia bark extract, taiwan beautyberry leaf extract, dyers woad leaf extract and baical skullcap root extract. The traditional Chinese medicine compositionfor the medical catheter of the invention has the functions of resisting bacteria, inhibiting bacteria, stop bleeding, relieving inflammation, calming mind and relieving pain, and is applied to a prostatic expanding cracking catheter. Compared with catheters in the current market, the catheter of the invention not only ensures the expanding cracking effect, but also has an effect of hemostasis with compression, relieves the compression on external sphincter, does not excessively damage the external sphincter, and prevents urinary incontinence and major bleeding. In addition, the catheter of the present invention can effectively avoid the damage that blood coagulates during surgery to generate thrombus cuased by the addition of foreign materials, and the tolerance of the size of a water bladder after free expansion and in a natural state is not large, thereby relieving the pain of the patient during the surgery.

Owner:江苏长寿棒科技有限公司

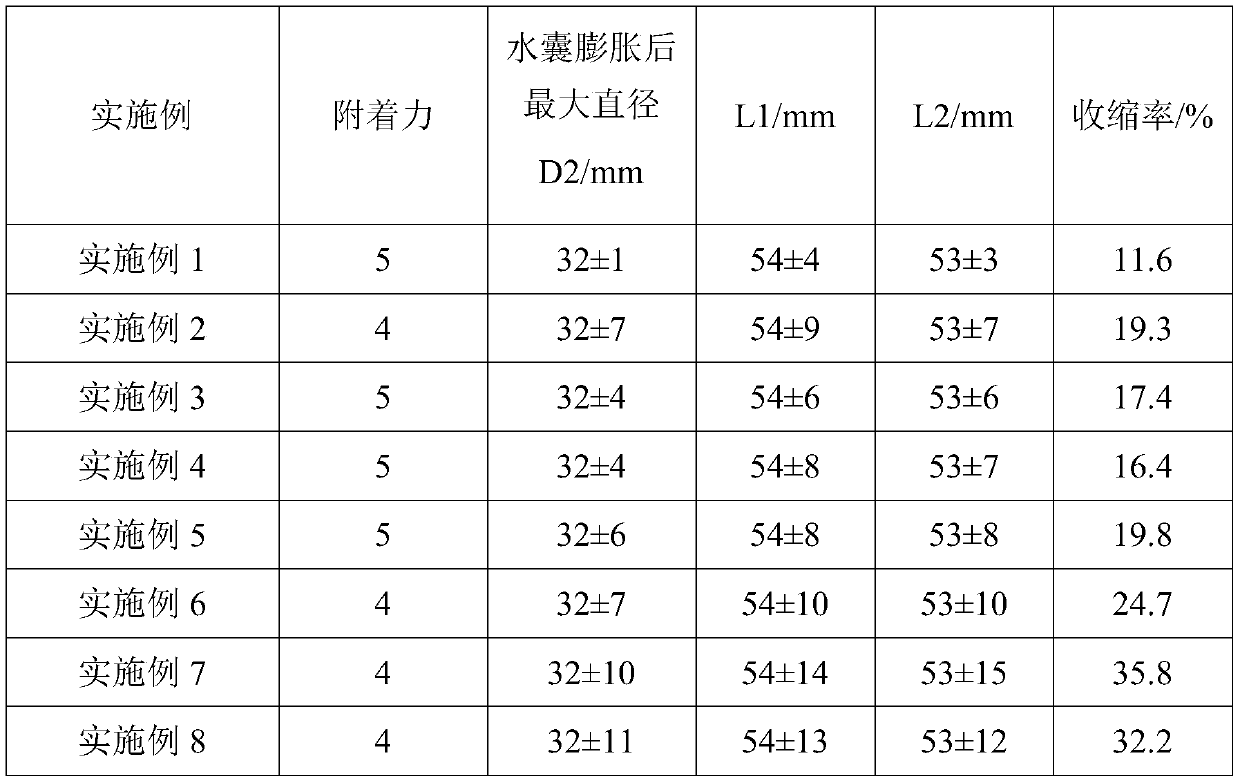

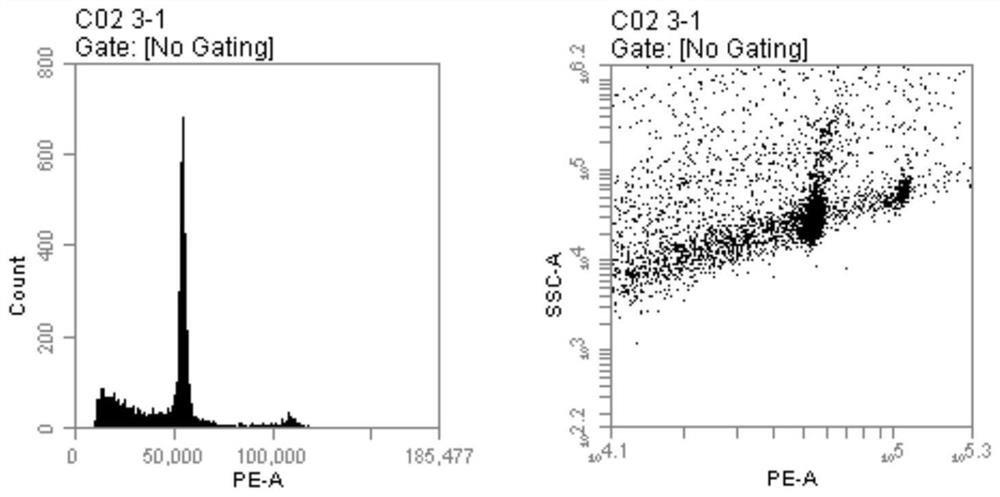

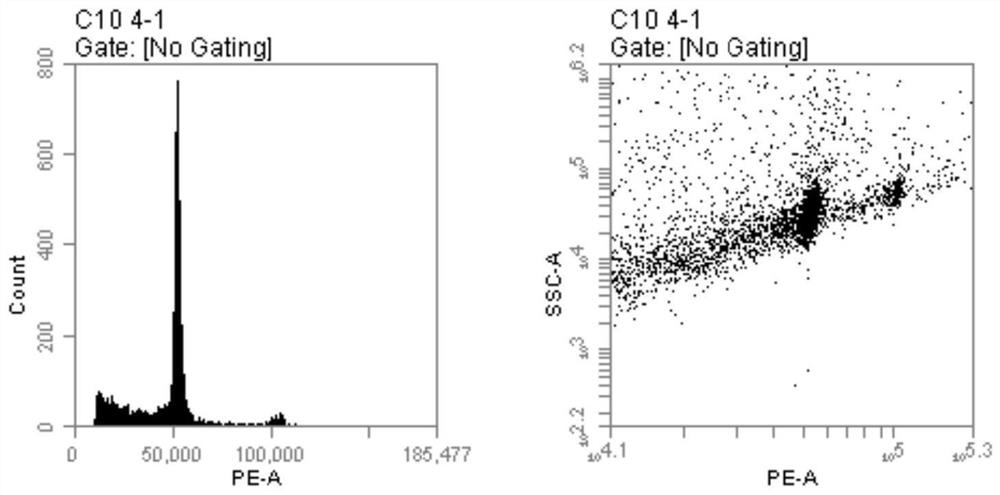

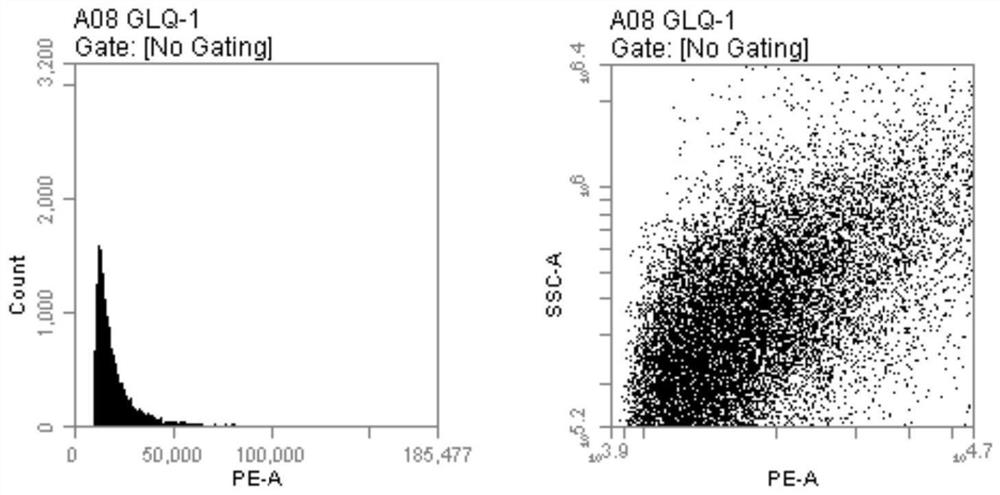

Preparation method suitable for mandulapalka flow cytometry sample and cell lysis solution

PendingCN114279786AGuaranteed cracking effectLess miscellaneous peaksPreparing sample for investigationIndividual particle analysisTissue sampleCytoplasm

The invention relates to the field of plant flow cytometry detection, in particular to a preparation method of a flow cytometry sample suitable for cyperus esculentus and a cell lysis solution. According to the preparation method, the cell lysis solution is added twice in the leaf slurry preparation process, so that the cell lysis effect is ensured, the number of obtained single cell nucleuses and the integrity of the cell nucleuses are improved, impure peaks detected and analyzed by a flow cytometer are reduced, and the detection accuracy is improved. Meanwhile, the improved cell lysis buffer solution suitable for preparation of the cyperus esculentus flow cytometry sample provided by the invention is used for treating a tissue sample, and all the components have a synergistic effect in a limited dosage range, so that complete cell nucleuses can be effectively released, residual cytoplasm fragments can be removed, and the influence of a phenol mixture on a result is reduced; the stability of cell nucleuses in the suspension liquid is kept, the agglutination is prevented, and the accuracy of flow cytometry analysis and detection is improved.

Owner:INST OF IND CROPS HENAN ACAD OF AGRI SCI

Camellia fruit crushing equipment for grain and oil processing

ActiveCN111495467BEfficient crushingNo manual operationFatty-oils/fats productionHuskingOil processingSilo

The invention relates to the technical field of grain and oil processing, in particular to camellia husk crushing equipment for grain and oil processing. The technical problem of the present invention is how to design a kind of camellia fruit crushing equipment for grain and oil processing with high crushing efficiency and no need for manual operation. A camellia fruit crushing equipment for grain and oil processing, including a frame, a silo, a crushing frame, a feeding mechanism, a crushing mechanism, a guide sleeve, a pallet, etc., the top of the frame is equipped with a silo, and one side of the lower part of the frame is fixed. The crushing frame is connected, and the other side of the lower part of the frame is equipped with a feeding mechanism. The side of the crushing frame close to the feeding mechanism has a material inlet. The frame above the crushing frame is equipped with a crushing mechanism. A guide sleeve is connected, and a supporting plate is slidably arranged in the guide sleeve. The invention can effectively crush the camellia fruit through the cooperation of the feeding mechanism and the crushing mechanism without manual operation and saves manpower.

Owner:邓志杰

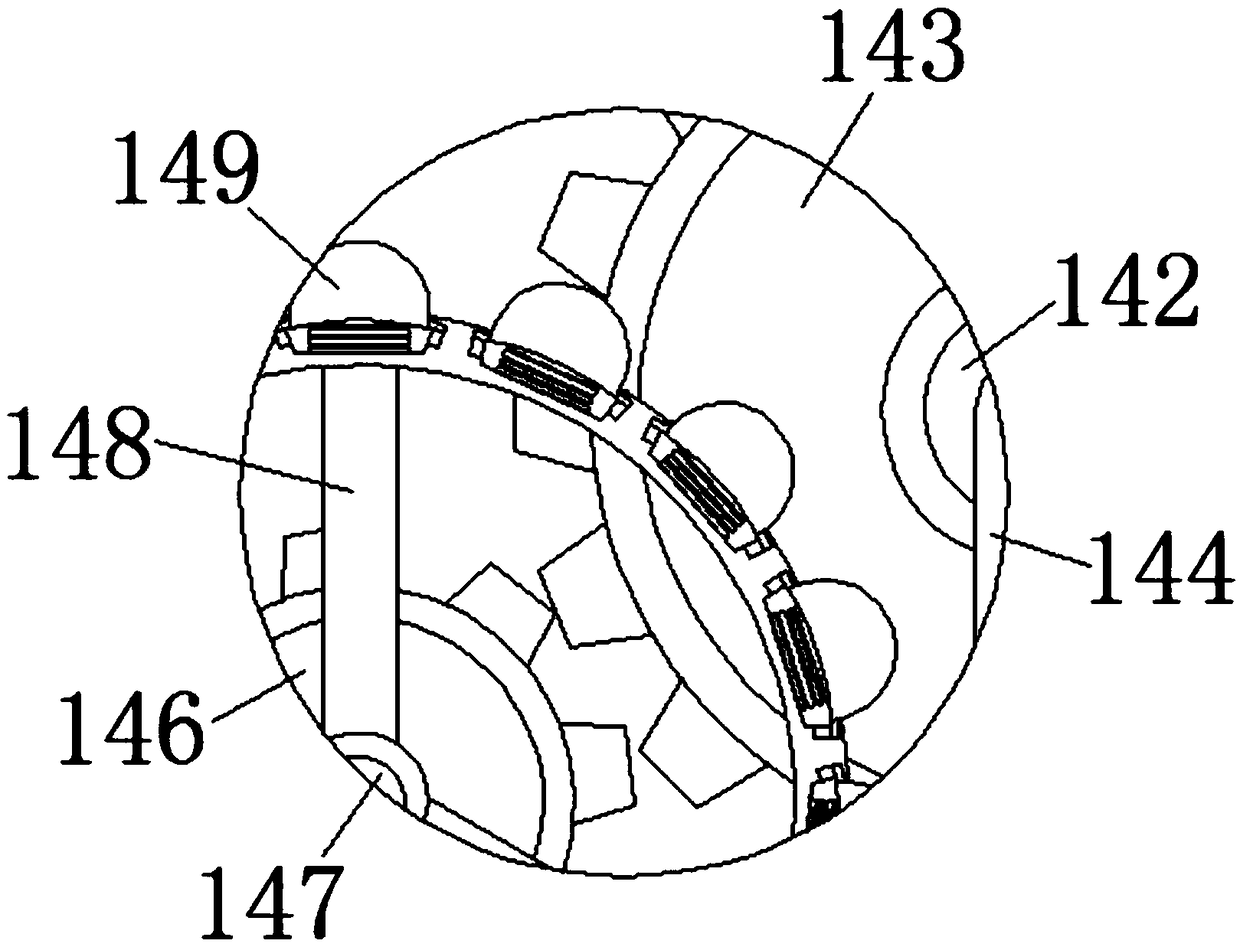

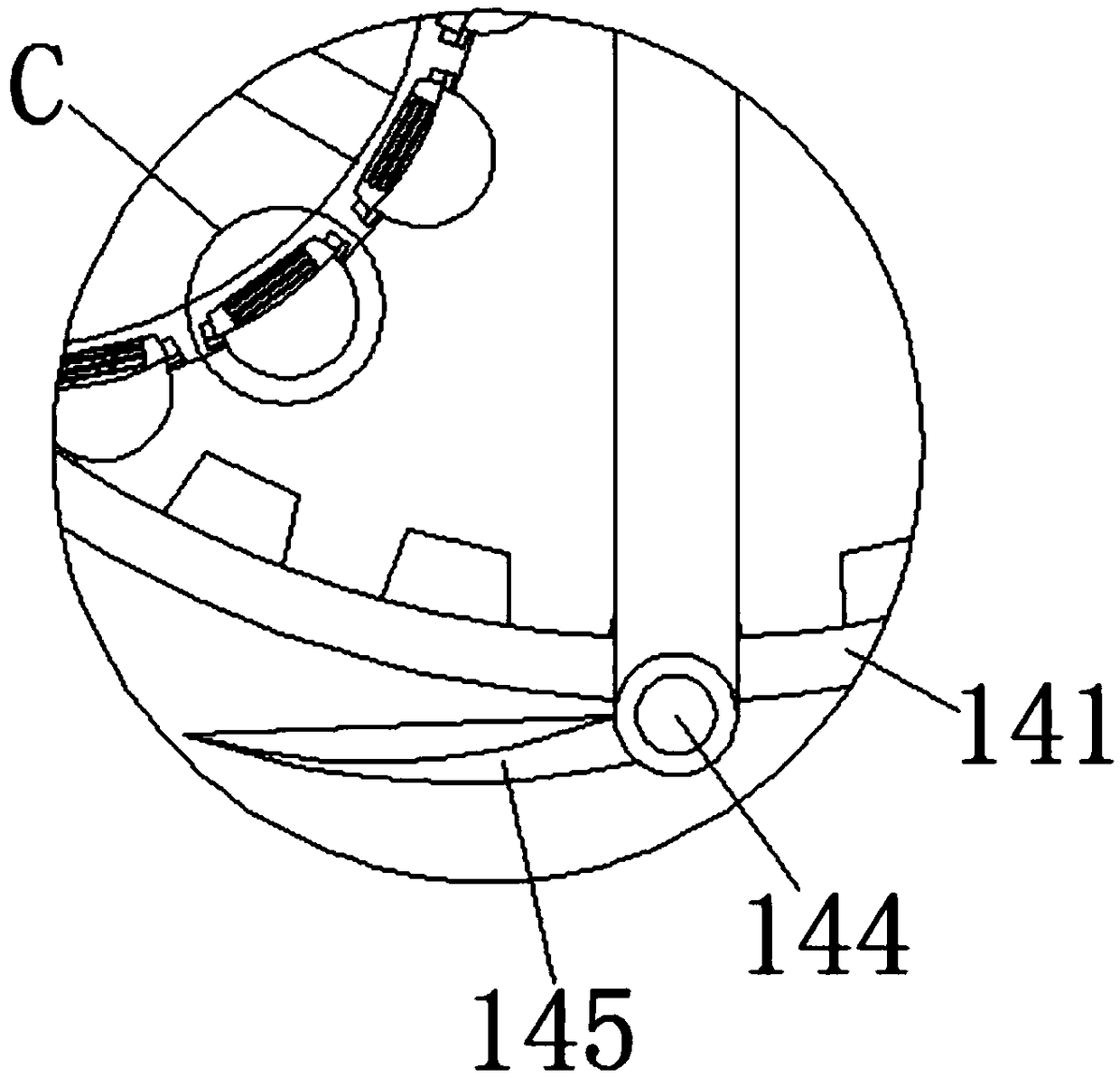

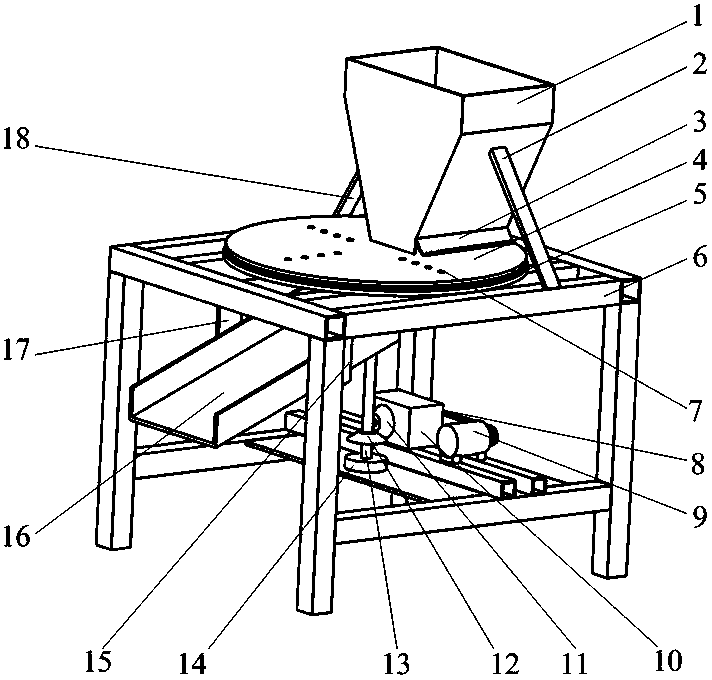

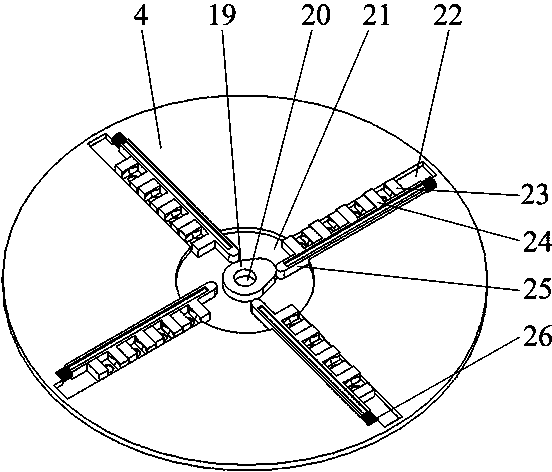

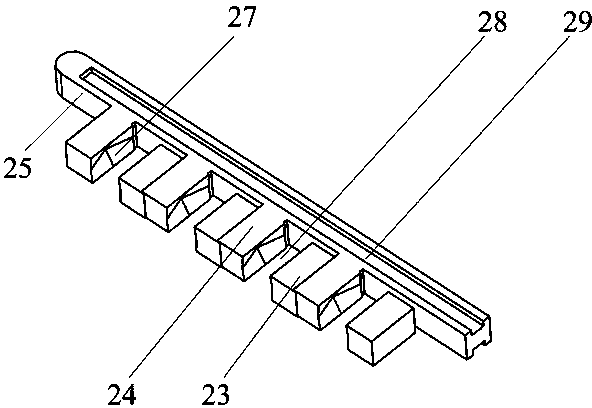

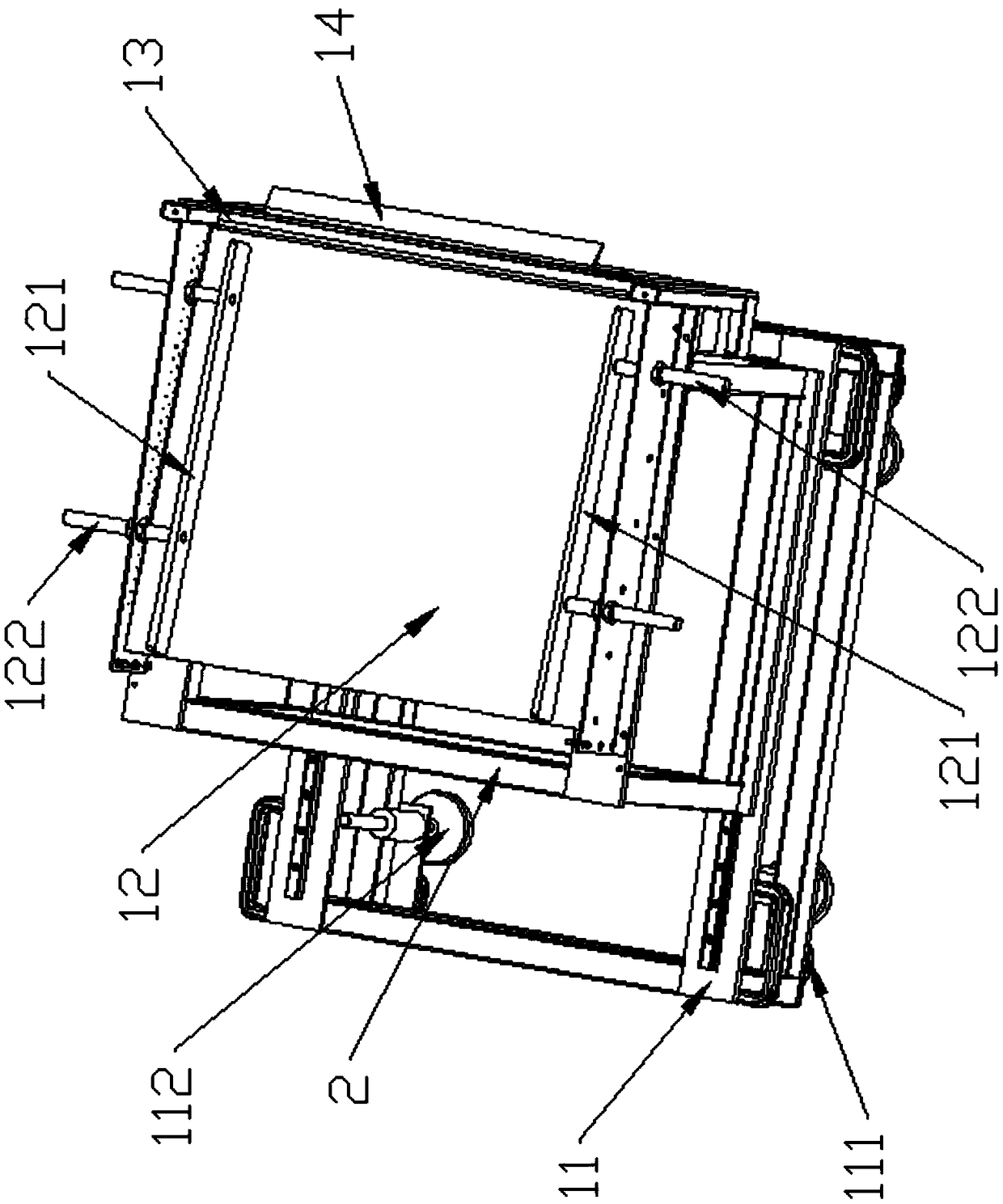

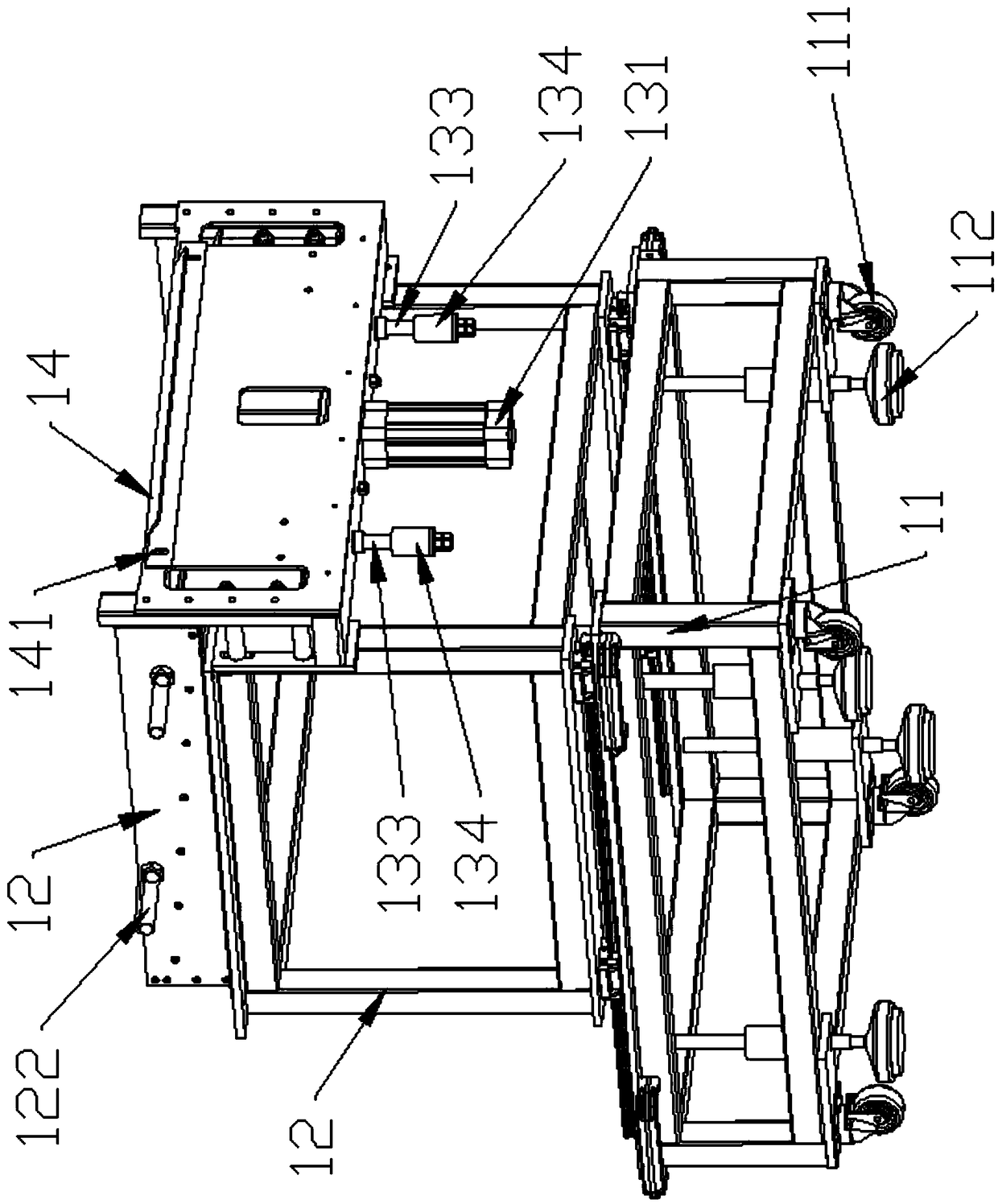

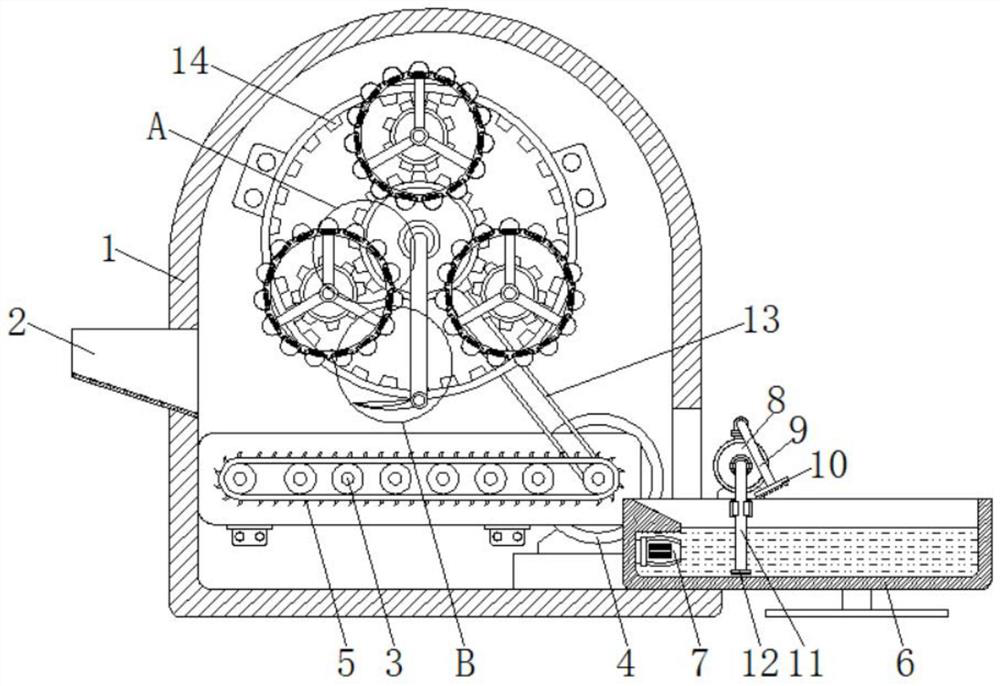

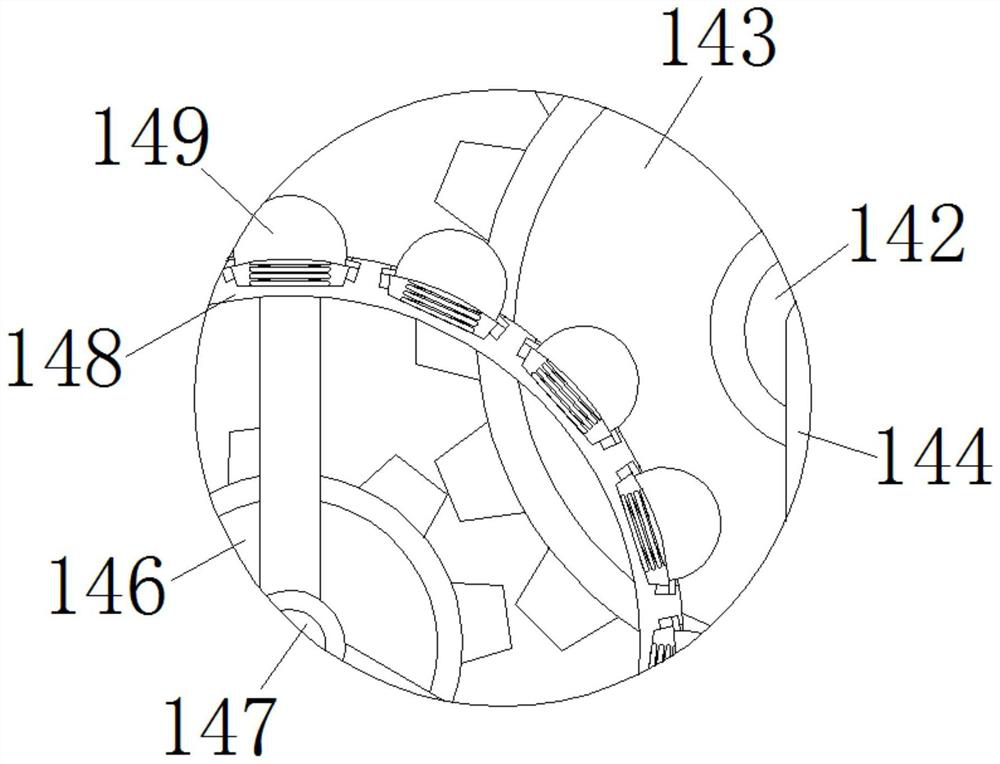

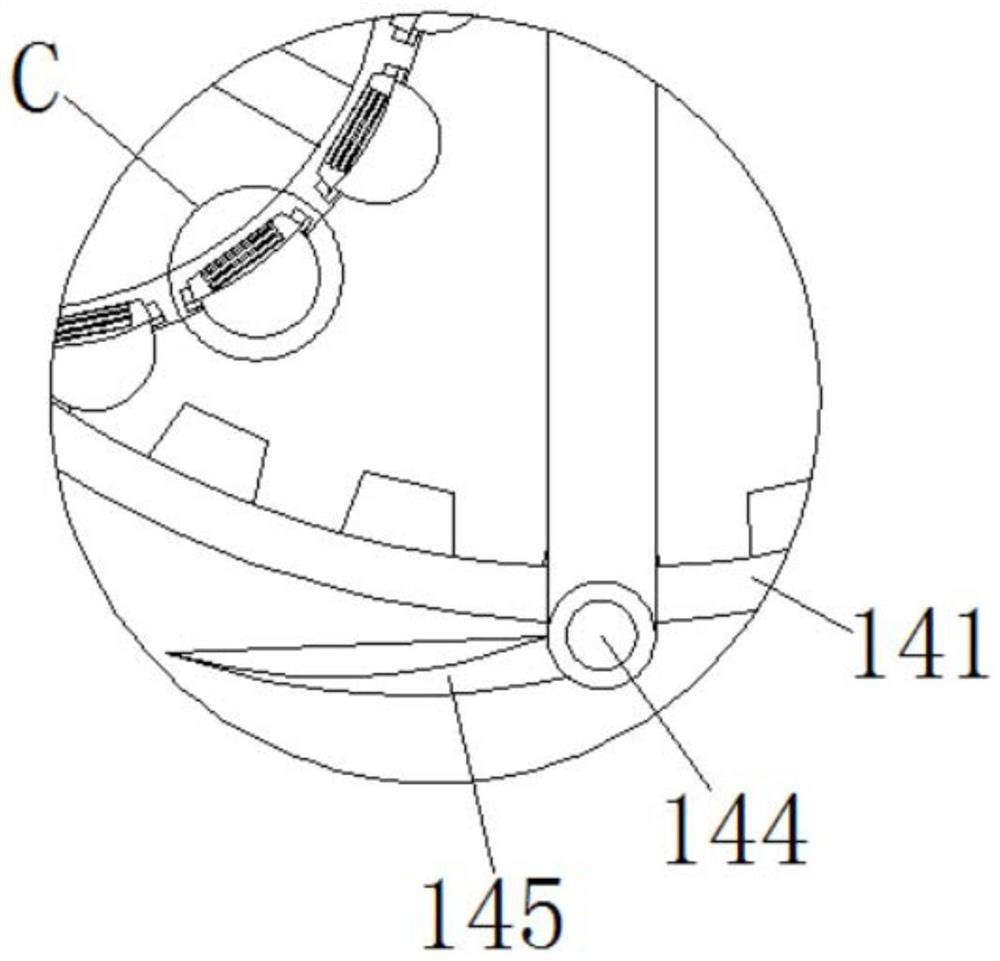

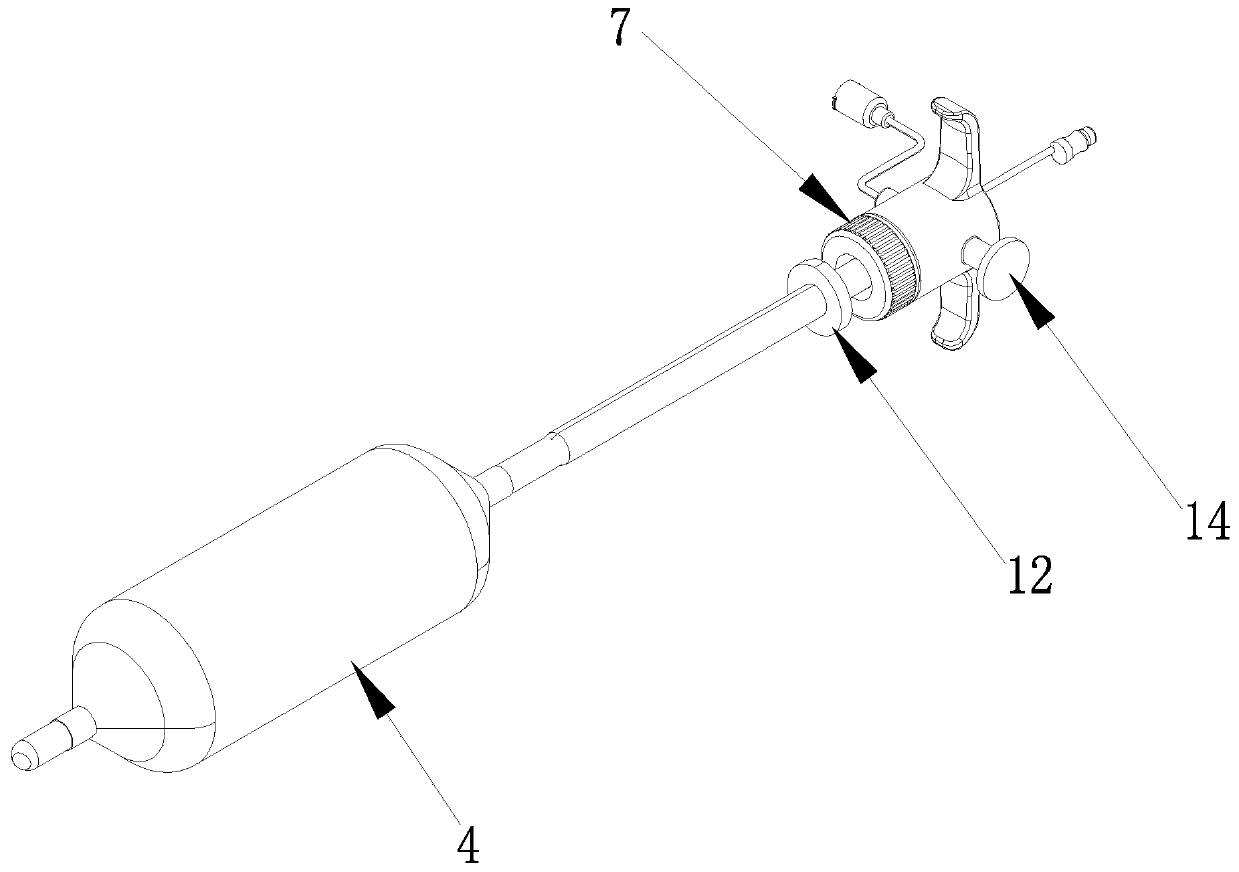

Staggered-pliers-type hazel shell cracking machine

The invention discloses a staggered-pliers-type hazel shell cracking machine consisting of a rack as well as a hazel feeding device, a hazel shell cracking device, a hazel discharging device and a power drive device arranged on the rack. The staggered-pliers-type hazel shell cracking machine is characterized in that a material taking turntable is combined with a feeding hopper and a cleaning brush to take hazels one by one, thereby effectively avoiding the phenomena of material feeding blockage and cracking repeatability; a cam is utilized to control a sliding extrusion arm to realize the staggered-pliers-type shell cracking between a sliding extrusion block and a fixed extrusion block, so that the shells of the hazels can be cracked efficiently and singly one by one, the stroke in the shell cracking process is controllable, and the damage rate of hazelnuts can be effectively reduced; an extrusion chamber is designed to simulate the hazel in shape and is not limited by the size of the hazel, so that the hazel is stressed uniformly, and the shell cracking effect is ensured; and the hazel shell cracking device is simple in structure and reliable in work mode and can be used for cracking the shells of other spherical or oval nut materials such as walnuts and almonds, thus being strong in transformation feasibility. The staggered-pliers-type hazel shell cracking machine is simple in structure, high in shell cracking efficiency, low in nut damage rate, reliable in work mode and convenient to promote and apply.

Owner:SHANDONG UNIV OF TECH

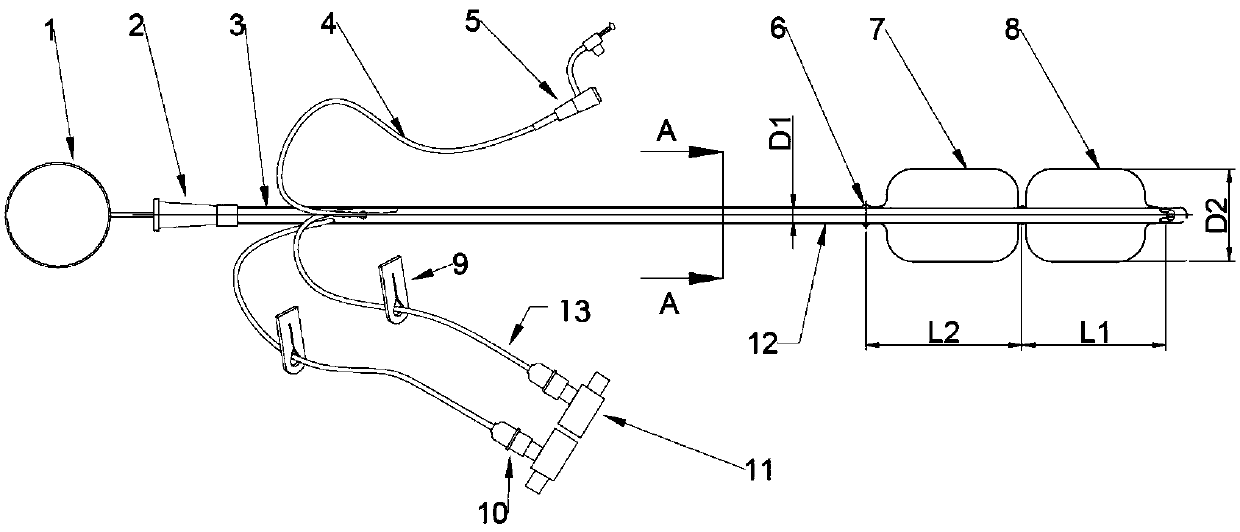

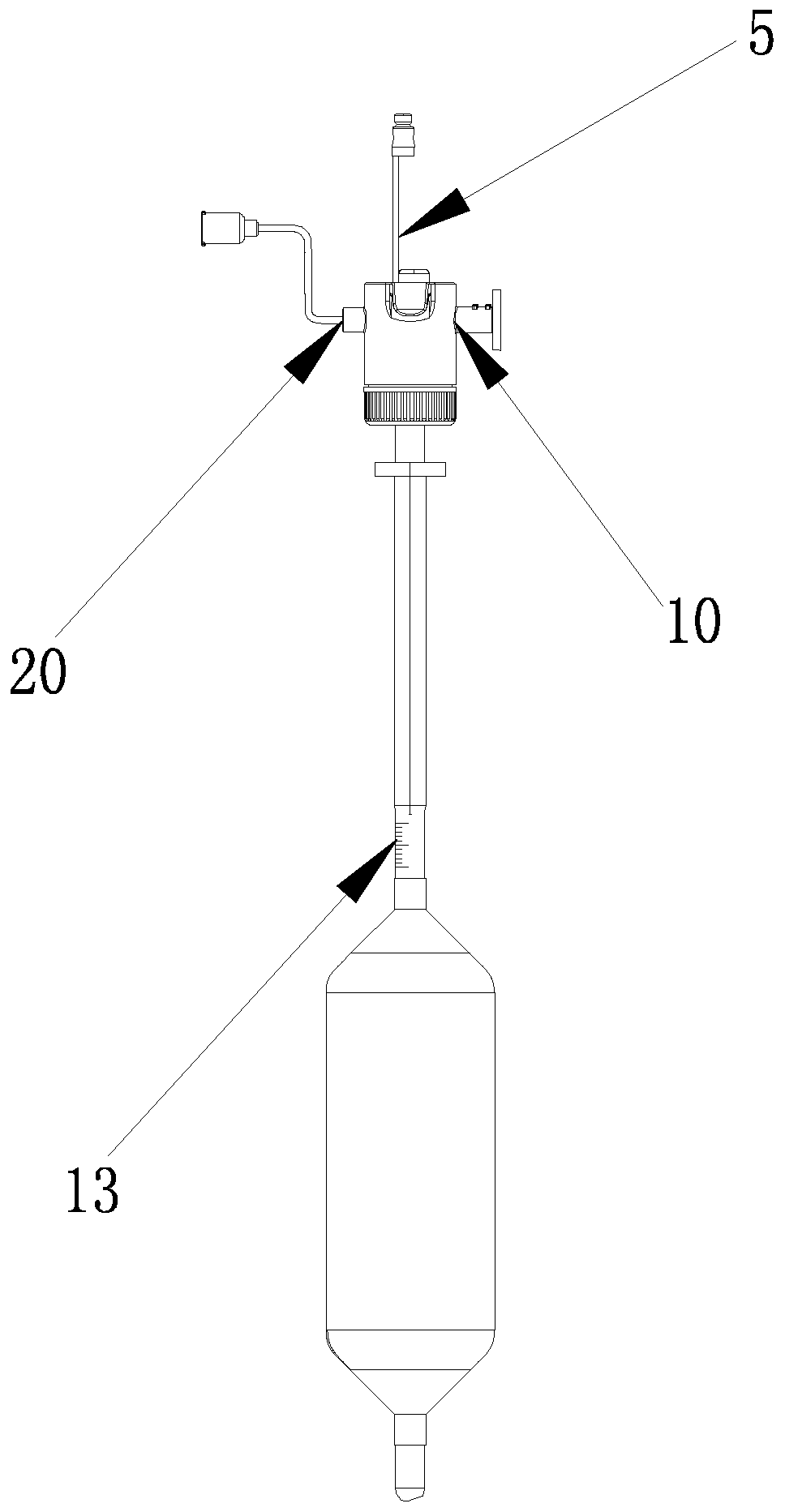

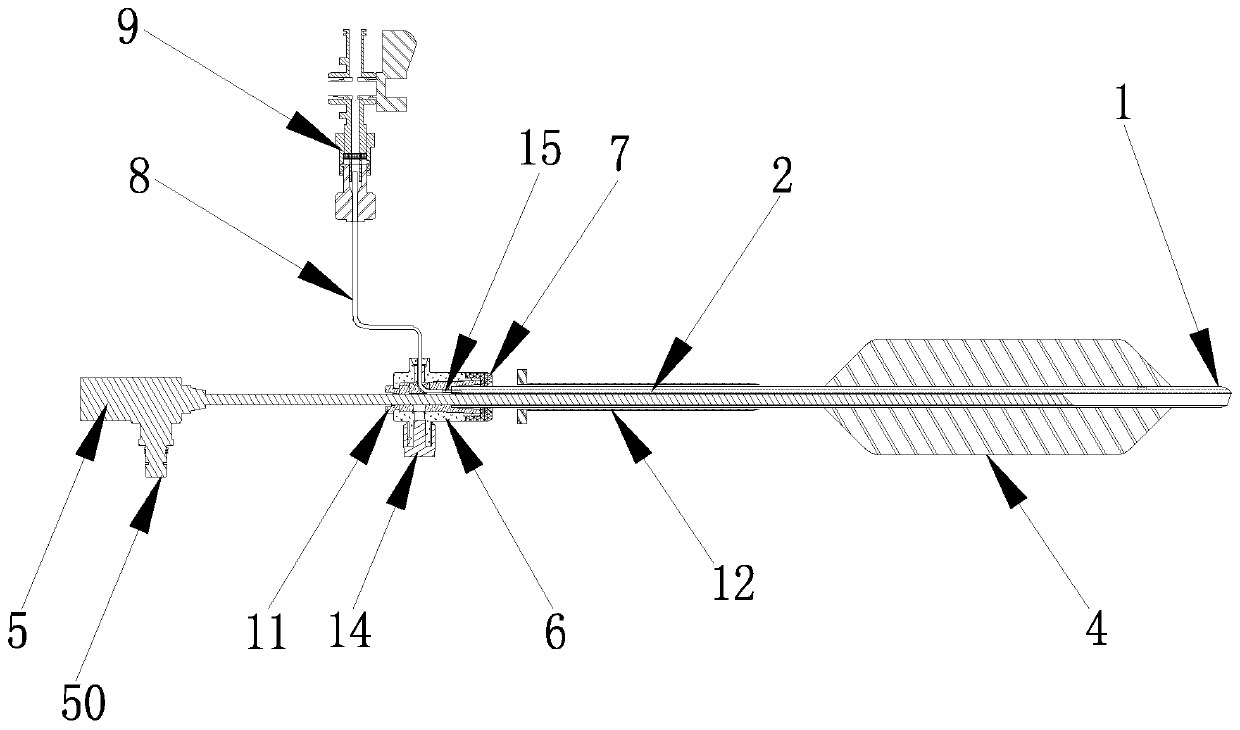

Transurethral prostatic dilatation catheter and method thereof

PendingCN109646793AConvenient and accurate positioningRelieve painSurgeryDilatorsThrombusNatural state

The invention relates to the field of medical instruments for prostate dilatation surgery, in particular to a transurethral prostatic dilatation catheter and method thereof. A TPU material is a hyperbranched polyurethane material. Compared with catheters in the current market, the prostatic dilatation catheter has the advantages that positioning of the catheter is more accurate and convenient, thecatheter can be kept fixed after the prostate is dilated, the dilatation effect is ensured, the hemostasis effect based on compression is achieved, the compression of the external sphincter is relieved, and the external sphincter cannot be excessively damaged, so that urinary incontinence and massive hemorrhage are prevented. In addition, the catheter can effectively avoid the situation that blood coagulation is caused in surgery due to the addition of foreign materials and correspondingly results in danger of thrombus. Moreover, the size of a water bag in a freely expanded state is almost the same as that in a natural state, so that the pain of a patient is relieved in a surgery process.

Owner:江苏长寿棒科技有限公司

A fracturing method for sub-stage circulation of low-pressure forward injection of low-temperature fluid in upward drilling

ActiveCN111894540BGuaranteed continuous injectionReduce air pressureFluid removalEngineeringExhaust pipe

The invention discloses an upward drilling negative pressure advancing type injection low-temperature fluid staged cycle fracturing method. First, water jet slotting equipment is used to set up three crack areas, and water is injected through a water injection pipe to fill up a hydraulic plugging device. In this way, three sealed fracturing chambers are formed, and the three sealed fracturing chambers are placed in a negative pressure state. Cryogenic fluid is injected into the three sealed fracturing chambers, and the cryogenic fluid fills each sealed fracturing chamber in turn, and the three sealed fracturing chambers are filled with low-temperature fluid. The fracture area in the fracturing chamber is subjected to cold impact fracturing. As the low-temperature fluid in the sealed fracturing chamber is heated and gasified by the geothermal heat, the internal pressure of the low-temperature fluid exhaust pipe exceeds the opening threshold of the safety pressure relief valve, and the safety pressure relief valve opens to make the corresponding The variable gas is discharged, thereby reducing the air pressure inside the low-temperature fluid exhaust pipe and each sealed fracturing chamber, so that the cycle is repeated, and the gas expansion force fracturing is performed on each sealed fracturing chamber multiple times. It can effectively ensure the rapid injection of low-temperature fluid and the cracking effect on coal and rock mass, and will not cause pollution to the surrounding environment.

Owner:CHINA UNIV OF MINING & TECH

Blast furnace slag liquid surface crust breaking device

ActiveCN107858462BEasy to operateSimple structureRecycling and recovery technologiesSlagLiquid surfaces

Owner:PANGZHIHUA PANGANG GROUP DESIGN & RES INST

A kind of sunflower seed shelling machine

ActiveCN105852157BGuaranteed cracking effectArranged horizontally evenlySievingScreeningEngineeringBrush device

The invention relates to a hulling machine for sunflower seeds. The hulling machine comprises a feeding hopper, a lifting conveying belt, a large and small seed separating sieve, an upper sieve vibrating device and a lower sieve vibrating device which are arranged below a material outlet at the top of the lifting conveying belt, grinding conveying belts arranged below the upper sieve vibrating device and the lower sieve vibrating device respectively, grinding rollers arranged in middles of the grinding conveying belts, brush devices arranged above the grinding conveying belts, arc-shaped collecting plates arranged at tail ends of the grinding conveying belts obliquely downwards, a rotating centrifugal barrel arranged below material outlets of the arc-shaped collecting plates, a centrifugal barrel discharging port arranged at the lower part of the rotating centrifugal barrel, a triple separating sieve arranged below the centrifugal barrel discharging port and multiple collecting tanks arranged at material outlets of all layers of the triple separating sieve, wherein the large and small seed separating sieve comprises an upper sieve and a lower sieve; the upper sieve extends obliquely downwards to above the upper sieve vibrating device; the lower sieve extends obliquely downwards to above the lower sieve vibrating device; sieve holes are formed in the upper sieve corresponding to the lower sieve.

Owner:巴彦淖尔市永明机械制造有限公司

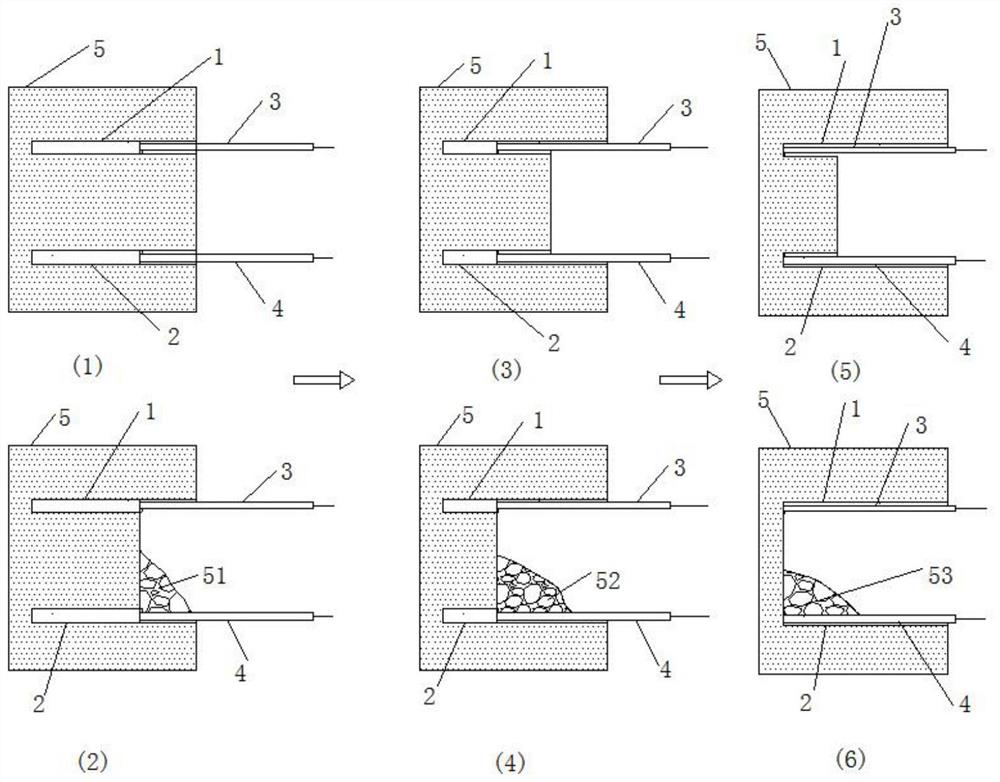

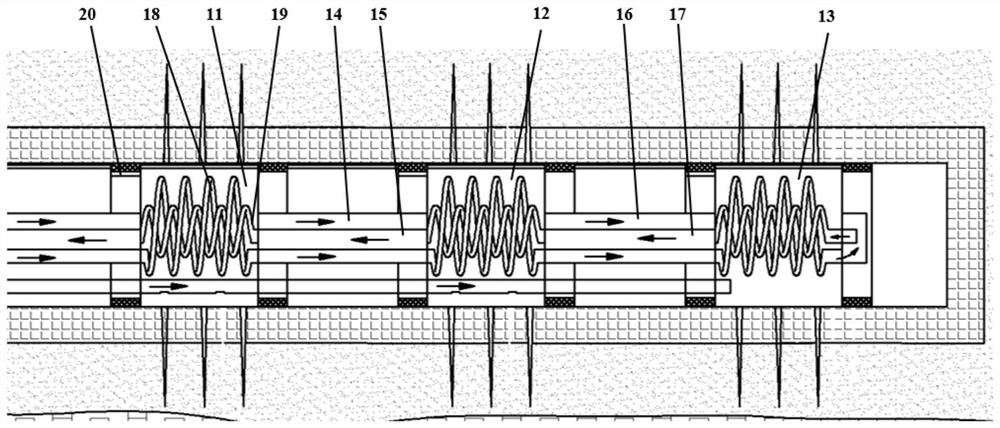

A method for staged fracturing with cryogenic fluid in horizontal wells

ActiveCN111980651BHigh frost heaving forceGuaranteed cracking effectFluid removalDirectional drillingHorizontal wellsEngineering

The invention discloses a method for grading fracturing with low-temperature fluid in a horizontal well. Firstly, three fracture areas are prefabricated by using a perforating gun, and then a water pressure plugging device is filled by injecting water through a water pipe, thereby forming three sealed fracturing chambers; The three sealed fracturing chambers are filled with supercooled water, and finally the low-temperature fluid flows through the internally threaded heat exchange tubes and externally threaded heat exchange tubes in the three sealed fracturing chambers in sequence. When the low temperature fluid flows through each sealed fracturing chamber, each The supercooled water in the sealed fracturing chamber exchanges heat with the low-temperature fluid. At this time, the temperature of the supercooled water drops rapidly, turning the water phase into ice and increasing its volume, so that each sealed fracturing chamber is fractured by using its ice swelling force, and the continuous After a certain period of time, stop and cycle for many times to complete the process of supercooled water ice expansion fracturing; not only can effectively ensure the fracturing effect of coal and rock mass and reduce the high pressure required for hydraulic fracturing, but also because the supercooled water has no chemical agents added, so It will not pollute the surrounding environment after leakage.

Owner:CHINA UNIV OF MINING & TECH

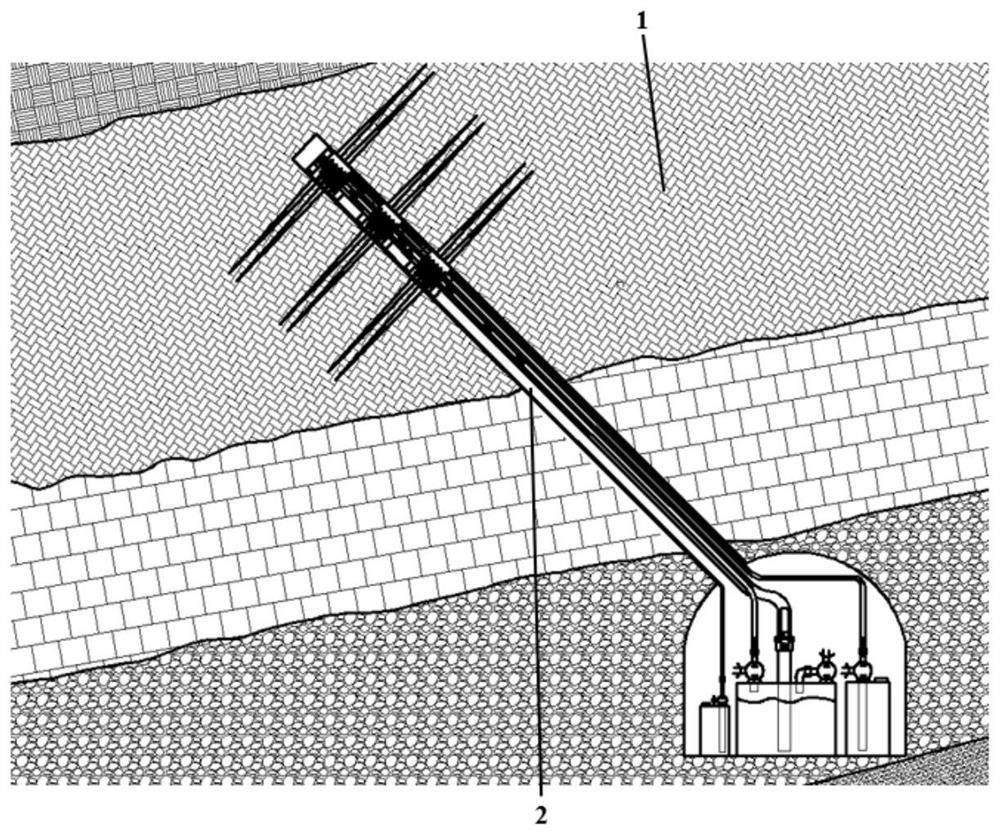

A staged fracturing method of cryogenic fluid for upward drilling

ActiveCN111980650BGuaranteed cracking effectCreate pollutionFluid removalDirectional drillingEngineeringHydraulic fracturing

The invention discloses a method for grading fracturing by low-temperature fluid in upward drilling. Firstly, three fracture areas are prefabricated by using a perforating gun, and then water is injected through a water pipe to fill up a hydraulic occluder, thereby forming three sealed fracturing chambers. ; Fill the three sealed fracturing chambers with supercooled water in turn, and finally the low-temperature fluid flows through the internal threaded heat exchange tubes and external threaded heat exchange tubes in the three sealed fracturing chambers in turn, and the low temperature fluid flows through each sealed fracturing chamber At this time, the supercooled water in each sealed fracturing chamber exchanges heat with the low-temperature fluid. At this time, the temperature of the supercooled water drops rapidly, making the water phase change into ice and increasing in volume, so that the ice expansion force is used to compress each sealed fracturing chamber. After a certain period of time, stop and cycle multiple times to complete the process of supercooled water ice swelling and fracturing; not only can effectively ensure the fracturing effect of coal and rock mass and reduce the high pressure required for hydraulic fracturing, but also because the supercooled water has no chemical agents Added, so there will be no pollution to the surrounding environment after leakage.

Owner:CHINA UNIV OF MINING & TECH

A new type of prostate dilatation catheter

ActiveCN109925589BConvenient and accurate positioningGuaranteed cracking effectBalloon catheterSurgeryUrinary incontinenceSphincter muscle

The invention relates to the field of medical equipment for dilatation of the prostate, in particular to a novel catheter for dilation of the prostate. A novel prostatic fissure catheter is provided with a catheterization cavity, a flushing cavity, and a high-pressure water bladder cavity. Compared with the catheters currently on the market, the prostate expansion catheter described in the present invention is more accurate and convenient in positioning, and can be kept fixed after the prostate is expanded to ensure the expansion effect, play the role of compression and hemostasis, and relieve the compression of the external sphincter , will not excessively damage the external sphincter, and prevent urinary incontinence and hemorrhage; in addition, the catheter of the present invention can effectively avoid blood coagulation during the operation due to the addition of foreign materials, resulting in the danger of thrombus, and the water bladder can be expanded freely and naturally The tolerance of the size in the state is not large, so that the pain of the patient is reduced during the operation.

Owner:江苏长寿棒科技有限公司

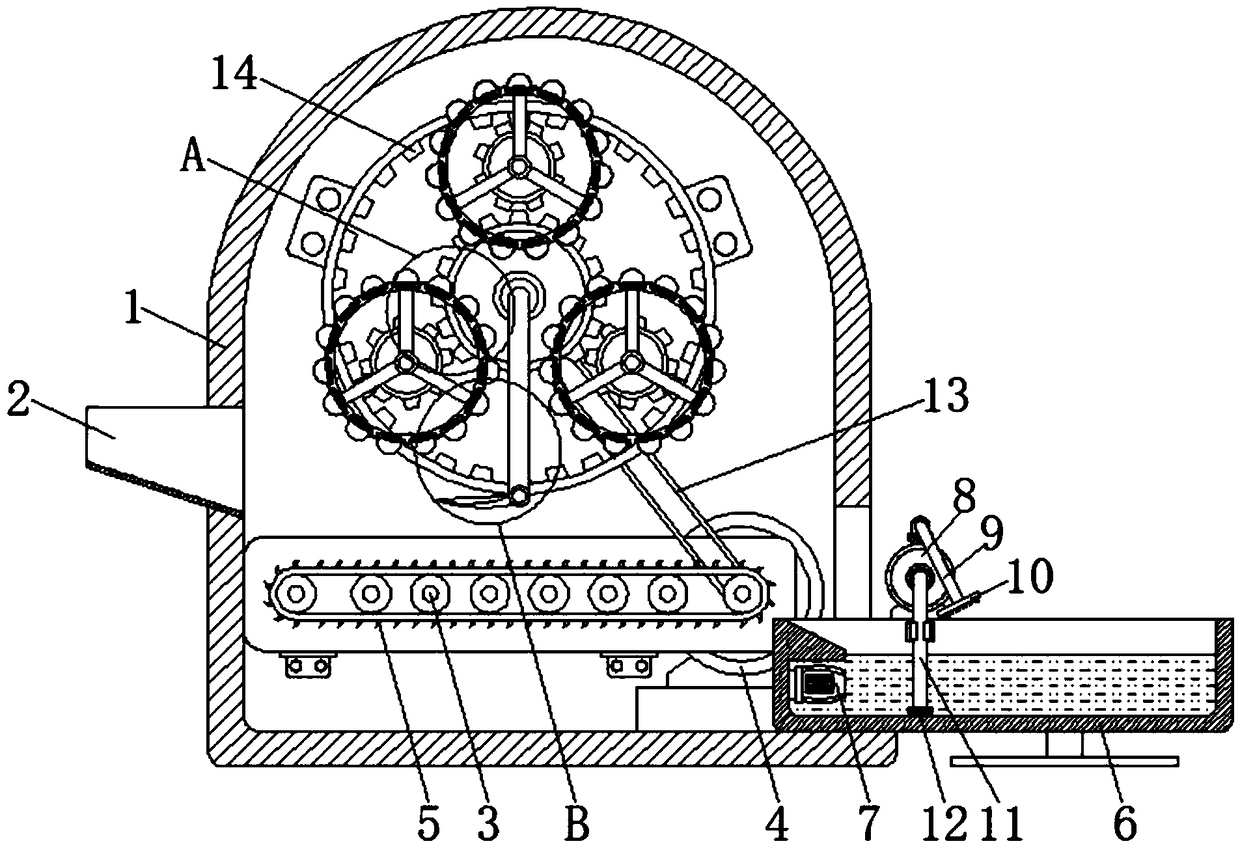

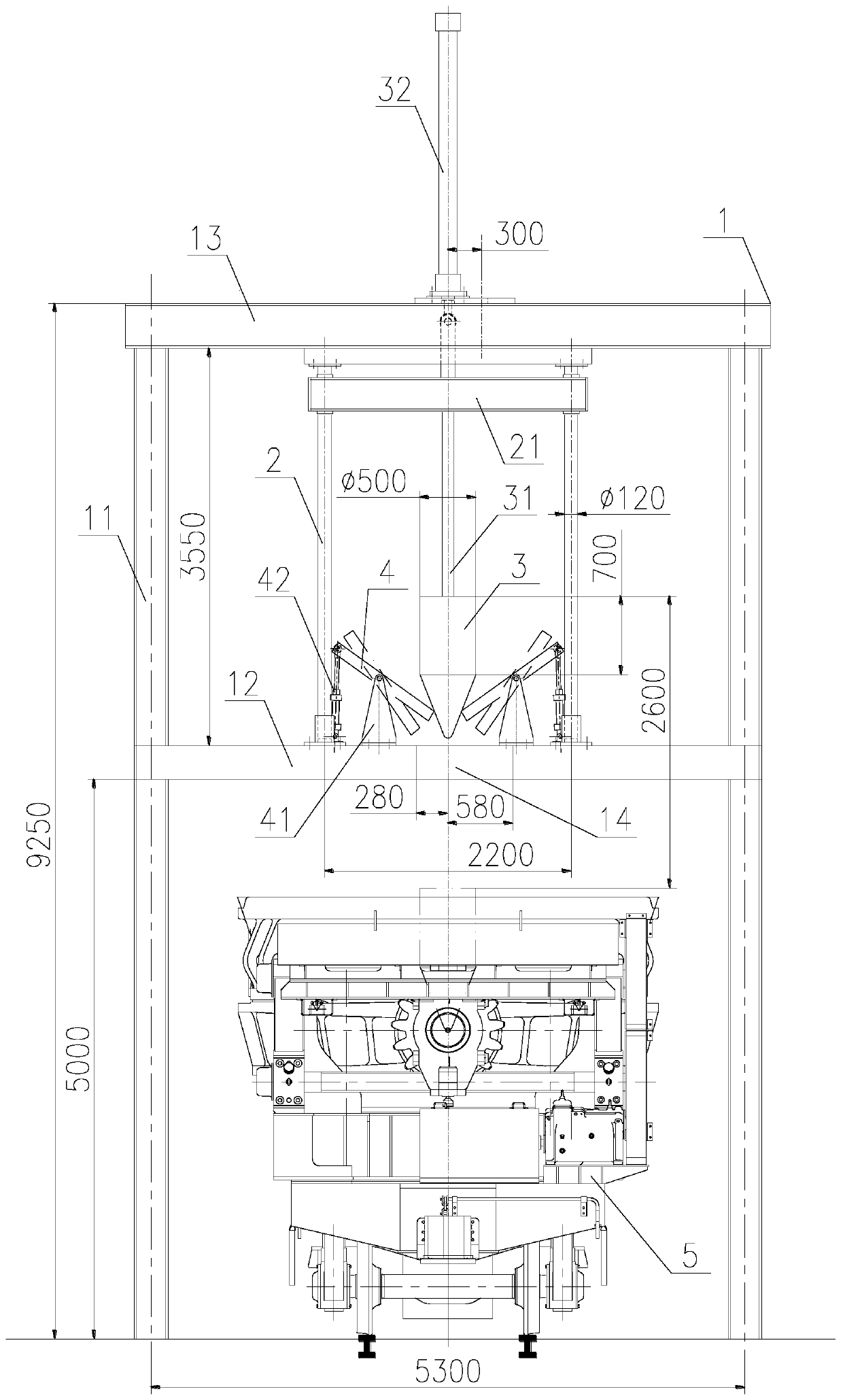

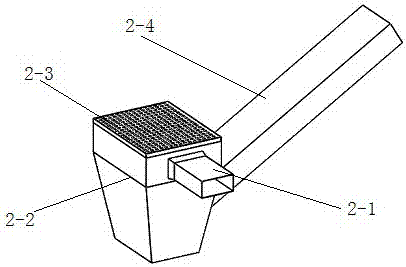

Eucommia ulmoides key-fruit shelling and automatic separating system

PendingCN114009800AGuaranteed cracking effectReasonable structural designMagnetic separationHuskingBiotechnologyMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to an eucommia ulmoides key-fruit shelling and automatic separating system, which comprises a vibration feeder, wherein a first hopper is fixed above the higher end of the vibration feeder, the lower end of the vibration feeder is connected with a collector in a flexible connection mode, the collector is in a duckbilled shape, and an electromagnet is fixed on the lower surface of the collector. The system has the beneficial effects that the system is reasonable in structural design and high in automation degree, shells, pulp and carpopodium of eucommia ulmoides key-fruits can be automatically separated, the labor consumption is reduced, and the working efficiency is improved; the raw materials do not need to be pretreated in the early stage, separated coarse eucommia ulmoides gum threads are complete, a large amount of materials are conveyed through wind power, separated kernels are pure, and a guarantee is provided for development and utilization of eucommia ulmoides gum in eucommia ulmoides key-fruits and further extraction of effective components of the kernels; and the fruits can be crushed one by one after being automatically arranged, so that shell jamming and omission can be avoided, and the shell breaking effect of the eucommia ulmoides key-fruits is ensured.

Owner:NANYANG INST OF TECH +1

Spiral feeder of cracking furnace for plastic garbage

InactiveCN107446608AGuaranteed cracking effectSolve Wobble ProblemsProductsReagentsWear resistantEngineering

A screw feeder for a plastic waste pyrolysis furnace, which is connected with a lower shaft seat through a connecting rod at the lower part of the feeder outer cover, the lower shaft seat is connected with the lower end of the feed shaft through a bearing, and the lower shaft seat supports the feed shaft The lower end, the upper end of the feed shaft and the upper cover are connected by bearings, realizing the up and down support of the feed shaft, which can effectively solve the swing problem of the feed shaft in the existing suspension setting during the rotation process, and avoid the feed shaft and the feed shaft. The friction between the outer covers of the feeder ensures the service life of the equipment. The upper part of the outer cover of the feeder of the present invention is a straight barrel, and the lower part is a flared conical barrel. The inner wall of the straight barrel is provided with a heat-resistant and wear-resistant inner lining. The lining can effectively reduce the friction between the material and the feeder cover during the feeding process, ensuring the service life of the feeder cover.

Owner:HENAN DIZHILV ENVIRONMENTAL PROTECTION TECH CO LTD

A method for producing formaldehyde-free technological veneer for veneer solid wood multi-layer board assembly

ActiveCN111823336BImprove performanceGood sizingWood treatment detailsThermal wood treatmentWood veneerSolid wood

The present invention relates to a kind of formaldehyde-free technology veneer production method that is used for veneer assembly of multi-layer solid wood board, which comprises the following steps in sequence: (1) drying and repairing the wet veneer of economical fast-growing wood; (2) After treatment, wet veneer of economical fast-growing wood is assembled and coated with formaldehyde-free glue and cold-pressed into a slab; (3) The slab is kept under pressure and heated by high-frequency microwave; (4) Primary curing; (5) Secondary curing ; (6) Milling and deburring, sliced into formaldehyde-free technology veneer. This invention overcomes the shortcomings of the existing small-diameter wood and thin-diameter wood that can only be used to make particleboards, consumes a large amount of glue, and is not environmentally friendly. It cooperates with the optimal type of formaldehyde-free glue, the optimal amount of glue, and the optimized embryonic production process. , realized the use of small-diameter wood and small-diameter wood to produce formaldehyde-free technology veneer with good performance. The formaldehyde-free technology veneer not only has low content of harmful substances, is green and environmentally friendly, but also can effectively reduce problems such as fried squares, burrs, and cracks during the production process. occur.

Owner:小森新材料科技有限公司

A method for fracturing with sub-stage circulation of negative pressure back-injection low-temperature fluid

ActiveCN111894541BGuaranteed continuous injectionNo high air pressureFluid removalAir pumpEngineering

The invention discloses a negative pressure retreat type injecting low-temperature fluid staged circulation fracturing method. Firstly, three crack areas are prefabricated by using a perforating gun, and then the rubber plugging device is filled with water through a water pipe, thereby forming three sealing pressure zones. The three sealed fracturing chambers are placed in a negative pressure state through the air pump, and low-temperature fluid is injected into the three sealed fracturing chambers. The low-temperature fluid fills each sealed fracturing chamber in turn. The fracture area is subjected to cold impact fracturing, and as the low-temperature fluid in the sealed fracturing chamber is heated and gasified by the geothermal heat, after the internal pressure of the low-temperature fluid exhaust pipe exceeds the opening threshold of the safety pressure relief valve, the safety pressure relief valve opens to discharge the gas, thereby The air pressure inside the low-temperature fluid exhaust pipe and each sealed fracturing chamber is reduced, and the cycle is repeated, and the gas expansion force fracturing is performed on each sealed fracturing chamber multiple times. It can effectively ensure the rapid injection of low-temperature fluid and the cracking effect on coal and rock mass, and will not cause pollution to the surrounding environment.

Owner:CHINA UNIV OF MINING & TECH

A method of pre-damage and fracture of hard rock based on high-voltage pulse electric explosion

ActiveCN111912309BGuaranteed cracking effectAvoid edge flashoverBlastingHigh voltage pulseGeophysics

The invention discloses a hard rock pre-damage and fracture method based on high-voltage pulse electric explosion, which is applied to the technical field of rock mass crushing and includes the following steps: 1. Drilling two holes in the rock mass to be broken, the first drilling hole and the second drilling hole. Two drill holes; 2. insert the first discharge electrode bottom of the first discharge electrode into the first drill hole, and insert the second discharge electrode bottom of the second discharge electrode into the second drill hole; 3. if the first discharge electrode and When the second discharge electrode is inserted into the first borehole and the second borehole for the first time, it is inserted into the bottom of the hole first, and the rock mass pre-damage operation is performed; if the first discharge electrode and the second discharge electrode are inserted into the first borehole and the second borehole for the first time , first insert the edge of the orifice to carry out the rock mass crushing operation. The invention is safe, reliable, green and efficient, and can be applied to many scenarios such as pre-damage of rocks encountered by hard boulders during excavation of shield machines, mining in mines, and breaking of large rocks in mines.

Owner:NORTHEASTERN UNIV LIAONING

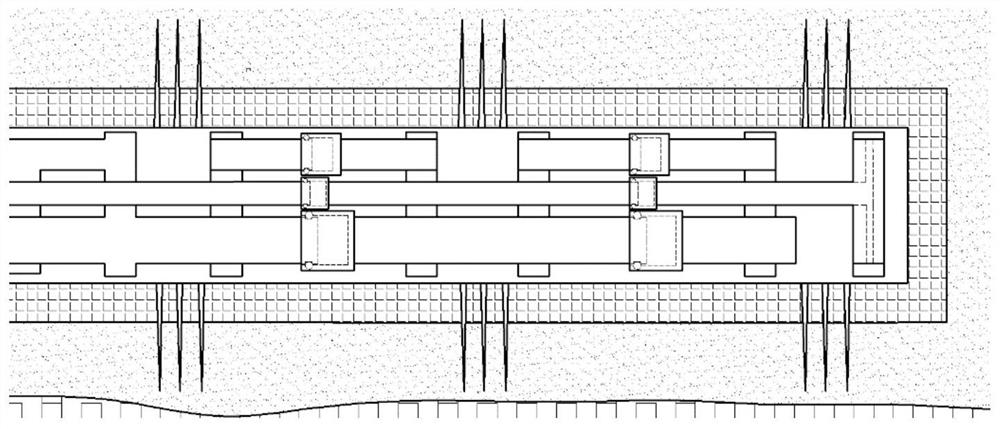

Rail disassembling device

The invention discloses a rail disassembling device and belongs to the field of steel machining equipment. The rail disassembling device comprises a feed component, a hammer-pressing component and a discharging component which are connected in sequence; the hammer-pressing component comprises a conveying track, a hammer-pressing plate, a hammer-pressing cylinder, a hammer-pressing box body and a crosser; the conveying track is arranged in a manner of penetrating through the hammer-pressing box body; the hammer-pressing cylinder is arranged at the two ends of the lower end face of the hammer-pressing plate; the hammer-pressing plate is fixedly connected with a force applying shaft of the hammer-pressing cylinder; one end, far away from the hammer-pressing plate, of the hammer-pressing cylinder is fixedly arranged on the bottom surface; the longitudinal center line of the hammer-pressing plate is arranged in parallel with that of the conveying track; the crosser is arranged at the internal top end of the hammer-pressing box body; the crosser and the hammer-pressing plate are arranged in a manner of corresponding to each other in the vertical direction; the conveying track is providedwith a plurality of rotating wheels; the rotating wheels are driven to rotate by the same motor and chain mechanism; each rotating wheel is provided with a positioning groove; and each positioning groove is arranged corresponding to a third profile of the rail. The rail disassembling device disclosed by the invention can realize automatic feeding, fracturing and discharging of the rail and is high in automation degree, high in work efficiency and low in labor intensity.

Owner:TIANJIN DAQIANG STEEL

A fracturing method for enhanced heat transfer with low-temperature fluid in horizontal wells

ActiveCN111980649BStrong pressing forceGuaranteed tightnessFluid removalDirectional drillingHorizontal wellsEngineering

The invention discloses a method for intensifying heat exchange and fracturing of horizontal wells with low temperature fluid. A perforating gun is used to set up multiple fracture areas, and water is injected through a water injection pipe to fill up a hydraulic plug to form a sealed fracturing chamber. The room is filled with supercooled water, and then low-temperature fluid is injected into the heat exchange section in the sealed fracturing chamber. The supercooled water exchanges heat with the low-temperature fluid through the heat exchange fins. Ice, after the phase change, the volume increases to use its ice expansion force to fracturing the sealed fracturing chamber. At the same time, after heat exchange, the low-temperature fluid will phase change to form gas, and the gas will pass through the gas discharge pipe and the well in turn under the influence of negative pressure. The annulus and the exhaust pipe are discharged, and the ice swelling and cracking process is completed after a period of time. Not only can it effectively ensure the fracturing effect of coal and rock mass and reduce the high pressure required for hydraulic fracturing, but also because no chemicals are added to the supercooled water, it will not pollute the surrounding environment after leakage.

Owner:CHINA UNIV OF MINING & TECH

A cauliflower vegetable cleaning device for cleaning vegetables

ActiveCN108835668BPlay a fixed effectGuaranteed cleaning effectFood treatmentAgricultural scienceVegetable processing

The invention discloses a cleaning device for cauliflower vegetables for cleaning vegetables, and relates to the technical field of vegetable processing. The cauliflower vegetable cleaning device for cleaning vegetables includes a machine body. A feeding frame is inserted into the left side of the body, and the feeding frame communicates with the inner cavity of the body. A conveyor belt is installed laterally in the body, and the conveyor belt is located at Below the right side of the feeding frame, the right end of the conveyor belt is driven by a drive motor, and the drive motor is fixedly installed on the right side of the bottom of the body, and a cleaning box is arranged under the right side of the conveyor belt. The cauliflower vegetable cleaning device for cleaning vegetables uses the barb to fix the cauliflower on the conveyor belt, and the blade cuts off the root of the cauliflower. The effective cleaning of the inside of the cauliflower solves the problem that the existing cauliflower cleaning device cannot fully clean the inside of the cauliflower.

Owner:澄果制药(山东)股份有限公司

Screw feeder for plastic garbage cracking furnace

InactiveCN107418610AUniform feedingPrevent leakageLiquid hydrocarbon mixture productionHydrocarbon oils treatmentEngineeringMechanical engineering

A screw feeder for a plastic waste pyrolysis furnace, which is connected with a lower shaft seat through a connecting rod at the lower part of the feeder outer cover, the lower shaft seat is connected with the lower end of the feed shaft through a bearing, and the lower shaft seat supports the feed shaft The lower end, the upper end of the feed shaft and the upper cover are connected by bearings, realizing the up and down support of the feed shaft, which can effectively solve the swing problem of the feed shaft in the existing suspension setting during the rotation process, and avoid the feed shaft and the feed shaft. The friction between the outer covers of the feeder ensures the service life of the equipment. The pitch of the feeding screw is related to the feeding speed and efficiency. If the feeding screw pitch is large, the feeding efficiency will be high, but the resistance to the rotation of the feeding screw will be large. If the feeding screw pitch is small, the feeding efficiency will be low, which will easily lead to cracking of the cracking furnace. The efficiency is low, but the present invention limits the pitch of the feeding screw to 1 / 3 of the outer diameter of the feeding screw, which can not only ensure the feeding efficiency, but also reduce the feeding resistance and save energy.

Owner:HENAN DIZHILV ENVIRONMENTAL PROTECTION TECH CO LTD

Use method of prostate dilation catheter

PendingCN110975116AConvenience guaranteedIdeas for Improving Observation Field of ViewBalloon catheterMulti-lumen catheterSurgical riskCatheter

The invention relates to a prostate dilation catheter, which comprises a main catheter, a balloon water injection cavity and a catheter main cavity are formed in the main catheter; a balloon water injection connector and a catheter water inlet connector are sequentially arranged at the rear end of the balloon water injection cavity and the rear end of the catheter main cavity respectively. The balloon water injection connector and the catheter water inlet connector are respectively communicated with the balloon water injection cavity and the catheter main cavity in sequence; a balloon is arranged at the front ends of the balloon water injection cavity and the catheter main cavity; the balloon and the main catheter at the front end of the balloon are made of transparent materials; the prostate dilation catheter is simple in structure and convenient in use, the balloon and the main catheter at the front end of the balloon are made of transparent materials, an endoscope is inserted into the main catheter in a penetrating mode, the main catheter and the balloon are matched with the endoscope, the use convenience of the endoscope is guaranteed, the thought of the observation view fieldof the endoscope is improved, the discomfort of the product in use is greatly reduced, the endoscope is used in cooperation, and the operation risk is reduced.

Owner:杭州汉士医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com