A method for fracturing with sub-stage circulation of negative pressure back-injection low-temperature fluid

A low-temperature fluid, retreating technology used in fluid production, earthmoving, wellbore/well components, etc., to solve problems such as weakening thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below.

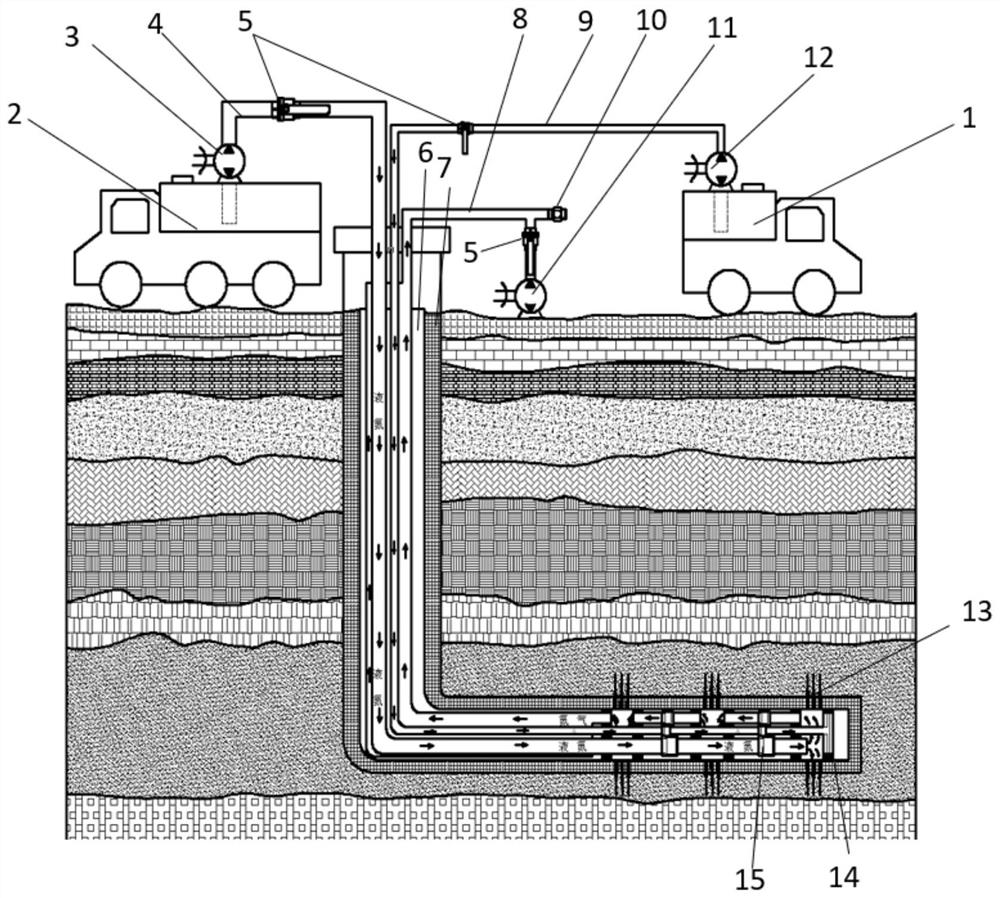

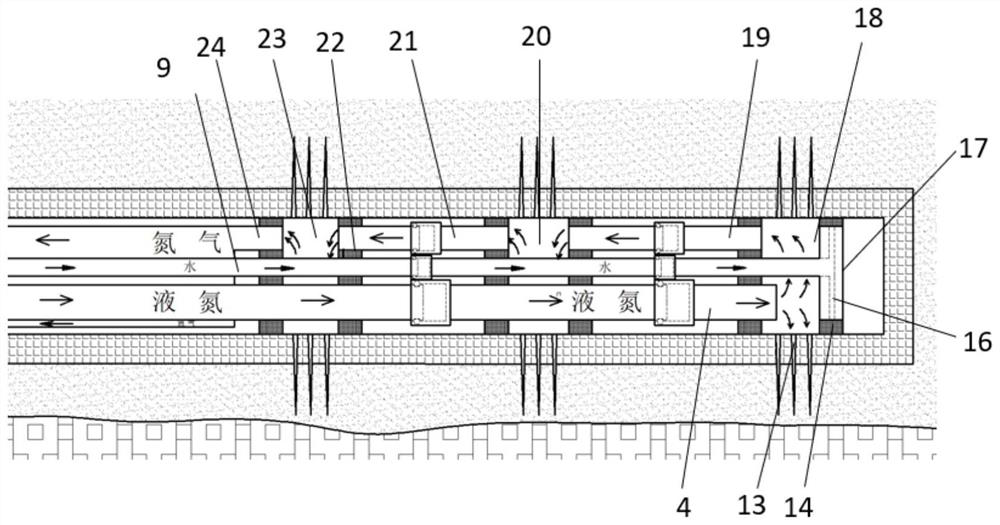

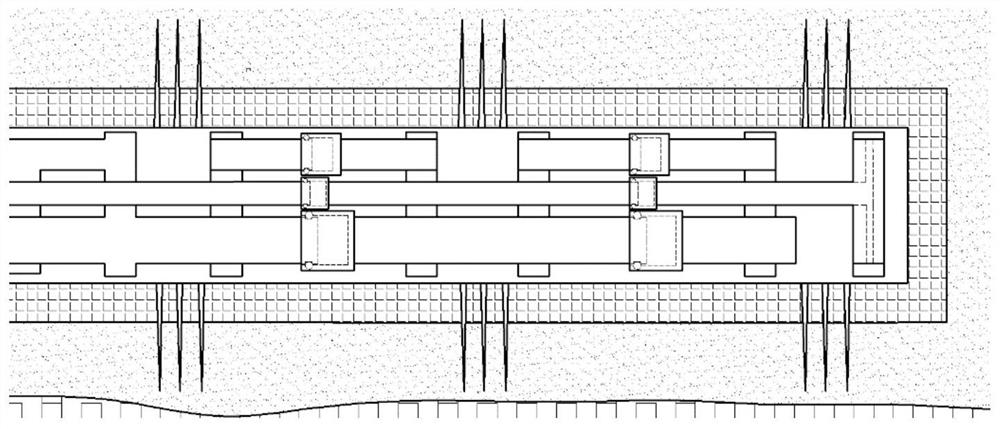

[0023] Such as Figure 1 to Figure 3 Shown, the concrete steps of the present invention are:

[0024]A. Drilling from the ground first, extend the perforating gun into the horizontal drilling, and prefabricate three fractured areas 13 at equal intervals along the direction perpendicular to the horizontal drilling with the axis of the horizontal drilling as the center, which are respectively the first fractured area and the second fractured area. The second crack zone and the third crack zone;

[0025] B. Choose a plurality of low-temperature fluid pipes to be connected end to end and form a low-temperature fluid channel 4 through quick-plug connectors 15. The low-temperature fluid channel 4 is divided into a horizontal section and a vertical section. Three sets of rubber sealing devices are installed in the horizontal section of the low-temperature fluid channel 4. They are respectively the first rubber plugging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com