Self damaging safe injector with blocking mechanism

A syringe and safety technology, which is applied in the field of self-destructing syringes, can solve the problems of difficult to achieve clogging, low production yield, and difficult process, and achieve the effects of reducing residual amount, reasonable structure and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

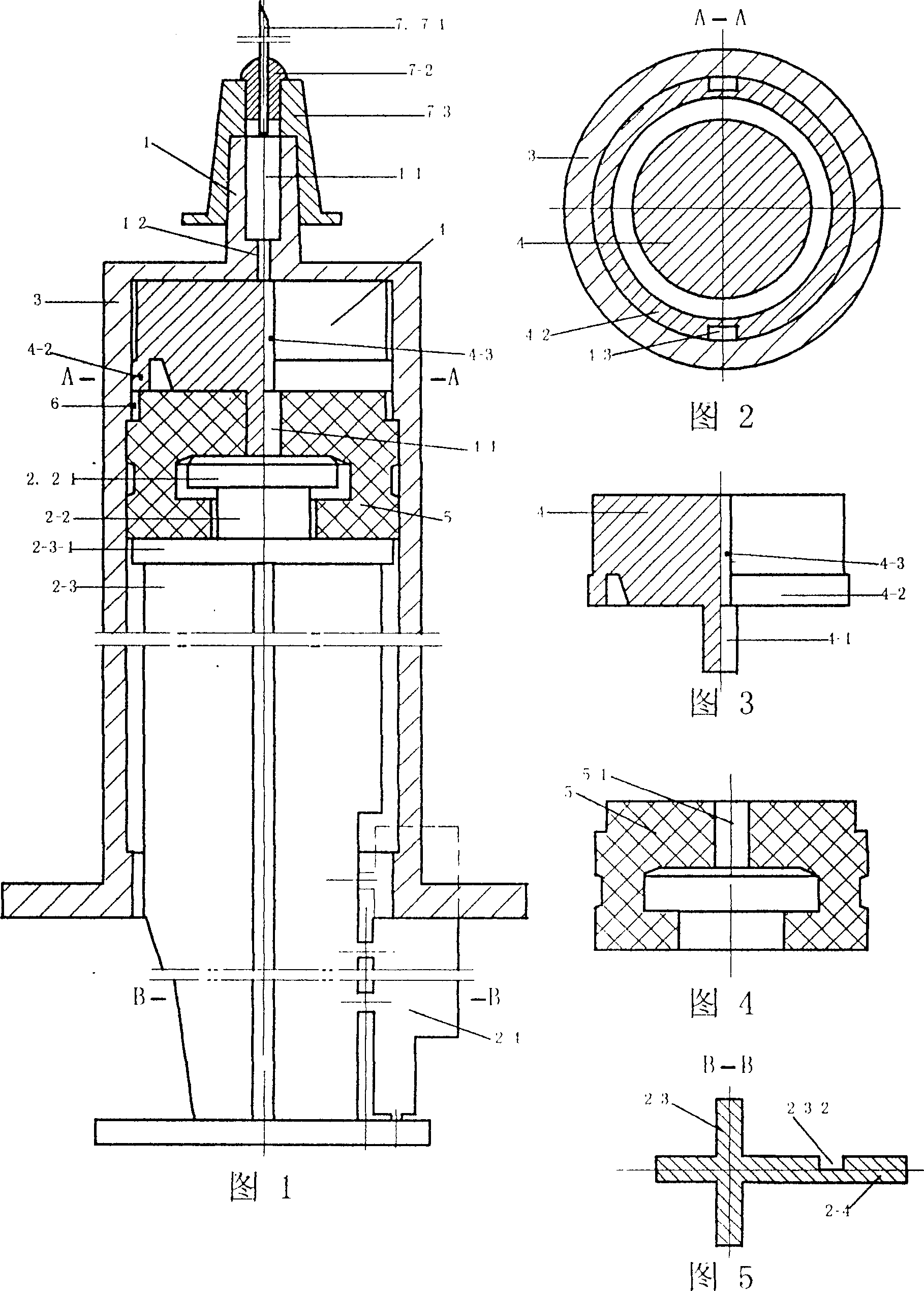

Embodiment 1

[0057] See Fig. 1 to Fig. 6, the material used in the syringe of this embodiment complies with the national standard. The applicable specification of the syringe of this embodiment is 10 milliliters and below 10 milliliters. The syringe of this embodiment has a cone head 1, a core rod 2, an outer jacket 3, and a piston 5. The cone head 1 has a cone head hole 1-1, and the cone head 1 and the outer jacket 3 are one piece. 1. An integral part of the neck 2-2 and the shaft 2-3, the piston 5 is sleeved on the head 2-1 of the core rod 2; see Fig. The locking card 4 is provided with an airtight positioning part 4-1, and the piston 5 is provided with a joint positioning part 5-1, and the airtight positioning part 4-1 of the blocking lock card 4 and the joint positioning part 5-1 of the piston 5 are inserted into each other to form an airtight combination Positioning, the airtight positioning part 4-1 of the blocking lock card 4 is a convex column, and the joint positioning part 5-1 o...

Embodiment 2

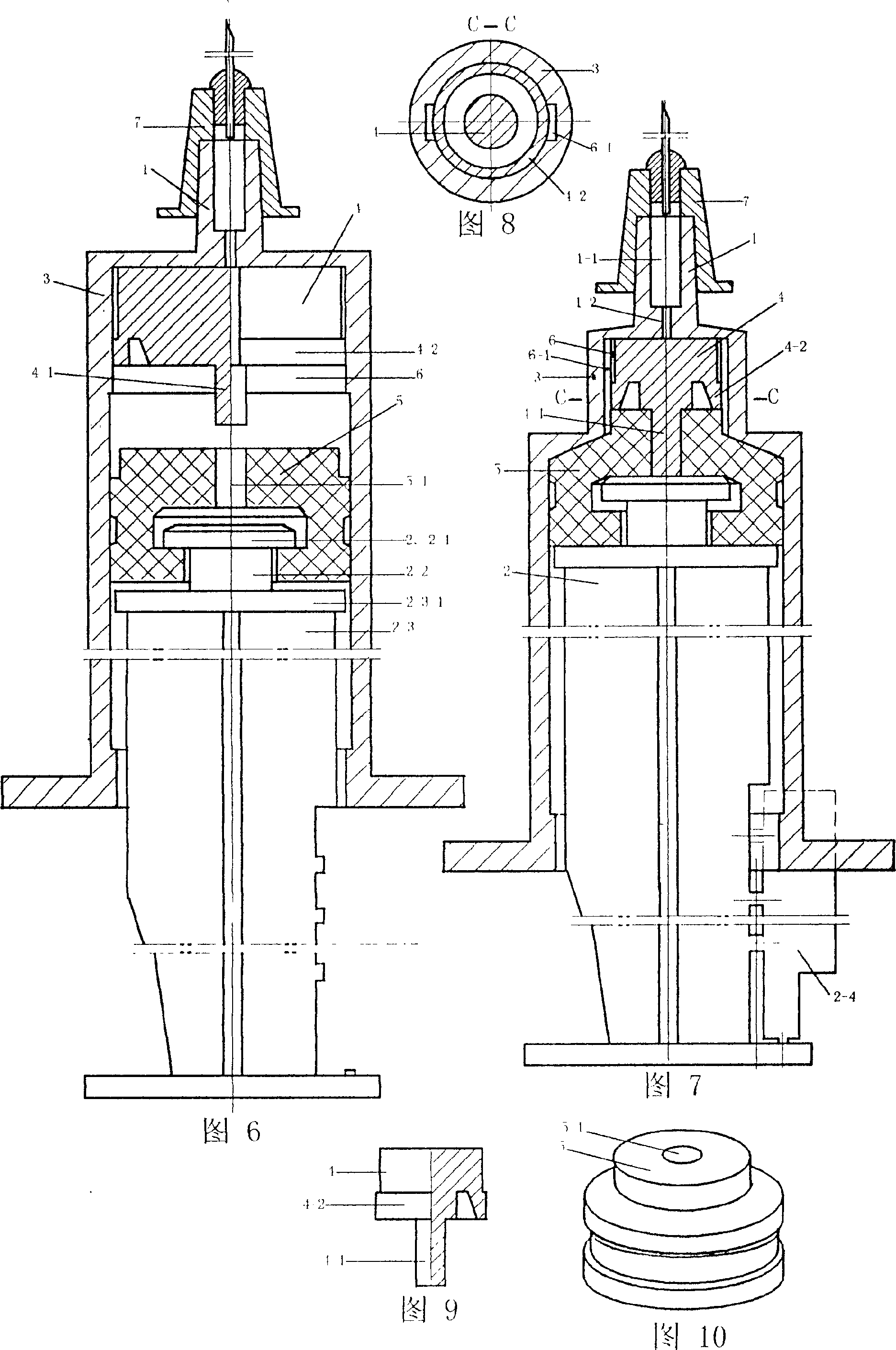

[0061] See Fig. 7 to Fig. 10, the applicable specification of the syringe of this embodiment is 5 milliliters and more than 5 milliliters. The overcoat 3 of the syringe of this embodiment is a stepped overcoat with a small top and a large bottom, and the stepped section at the upper end of the inside of the stepped overcoat 3 is used as a blocking cavity 6; the inner diameter of the blocking cavity 6 of the syringe of this embodiment is smaller than that of the overcoat 3 The inner diameter of the cavity is 8.5 mm; the two sides of the inner wall of the blocking cavity 6 are provided with an axial liquid guide groove 6-1; the blocking ring 4-2 of the blocking card 4 can cooperate with the blocking cavity 6, and the blocking card The outer diameter of the joint between the ring 4-2 and the blocking chamber 6 is 0.45 mm larger than the inner diameter of the blocking chamber 6; see FIG. 8, the blocking card 4 does not have an axial liquid guide groove 4-3. All the other are ident...

Embodiment 3

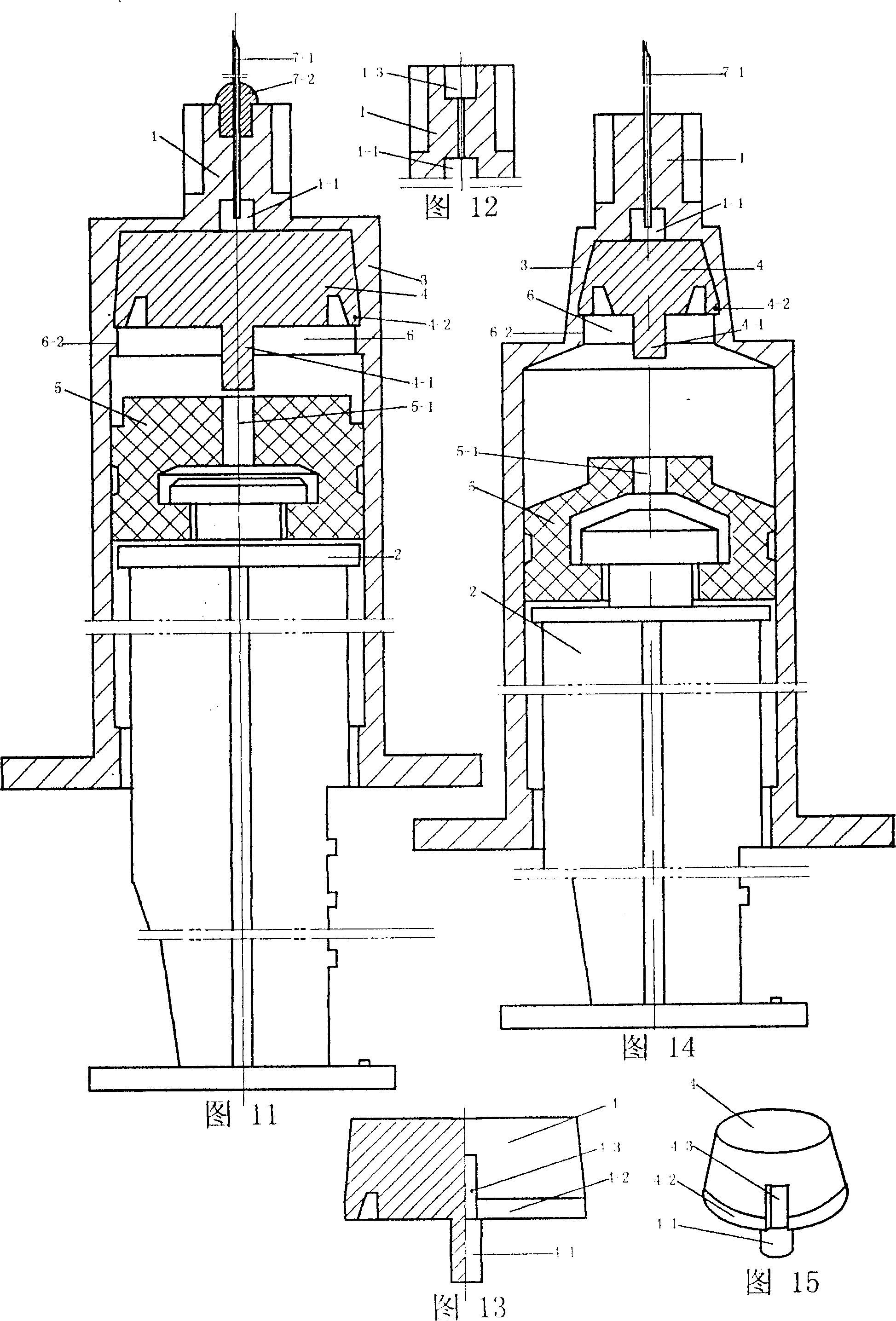

[0063] See Fig. 11 to Fig. 13, the specification that the syringe of this embodiment is applicable is 10 milliliters and below 10 milliliters. The needle tube 7-1 of the syringe of this embodiment is fixed on the cone head 1 by bonding the inner wall of the connecting hole 1-3 provided on the cone head 1 through the connecting part 7-2; the inner wall of the cone head hole 1-1 has no Anti-poking part 1-2; see Fig. 11, the inner wall of the upper section of the blocking chamber 6 has a taper that is small at the top and large at the bottom, and the upper section of the blocking card 4 has a corresponding taper that is small at the top and large at the bottom. The inner wall of the inner wall is provided with the blocking boss 6-2, and the inner diameter of the blocking boss 6-2 is less than the inner diameter of the junction of the upper section of the blocking cavity 6 and the blocking boss 6-2. The outer diameter of the locking snap ring 4-2 is greater than the inner diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com